The Ultimate Guide to Air Compressors and Accessories

Introduction

Air compressors are versatile tools that find applications in various industries and everyday tasks. Whether you're looking to power pneumatic tools, inflate tires, or manage compressed air systems, choosing the right air compressor and accessories is crucial. In this guide, we'll explore the world of air compressors, their different types, applications, and the essential accessories that enhance their performance. We'll also go over maintenance tips and signs that you need air compressor repairs or replacement. Finally, we'll dive into a bit of the history of Air Compressors.

1. Air Compressor Discharge Hoses

Overview

Air compressor discharge hoses are essential components that connect your compressor to pneumatic tools or other devices. They ensure a steady flow of compressed air, making them critical for efficient operation.

Top 5 Applications

- Pneumatic Tools: Connect hoses to power pneumatic tools like nail guns and impact wrenches.

- Tire Inflation: Ideal for inflating car and bicycle tires.

- Spray Painting: Used with paint sprayers for even and efficient coating.

- HVAC Systems: Hoses facilitate air transfer in heating, ventilation, and air conditioning systems.

- Automotive Maintenance: Essential for various automotive repair tasks.

Typical Characteristics

- Material: Rubber or PVC

- Length: Varies from a few feet to longer hoses for extended reach

- Diameter: Different hose diameters are available for specific applications

- End Fittings: Equipped with connectors for easy attachment

2. Air Compressor Motors

Overview

Air compressor motors are the heart of your compressor system. They provide the power needed to compress air and drive various pneumatic tools and equipment.

Top 5 Applications

- Compressor Operation: Motors drive the air compressor's pump, compressing air.

- Industrial Machinery: Used in various industrial applications requiring compressed air.

- Automotive Garages: Power pneumatic tools for automotive repairs.

- Construction Sites: Operate air-powered construction equipment.

- Manufacturing Processes: Support automated manufacturing with compressed air.

Typical Characteristics

- Horsepower (HP): Range from 1 HP for small compressors to 100+ HP for industrial units.

- Voltage: Available in various voltage options to suit different settings.

- Motor Type: Can be single-phase or three-phase, depending on the application.

- Enclosure: Motors come in open or enclosed designs for protection.

3. Air Compressor Accessories

Overview

Air compressor accessories are a diverse category of components that enhance the functionality and efficiency of your compressor system. These accessories include filters, regulators, lubricators, and more.

Top 5 Accessories

- Air Filters: Ensure clean and dry compressed air for pneumatic tools.

- Pressure Regulators: Control and adjust the air pressure to suit specific tasks.

- Lubricators: Provide lubrication to pneumatic tools for extended lifespan.

- Air Gauges: Monitor and display air pressure levels in the system.

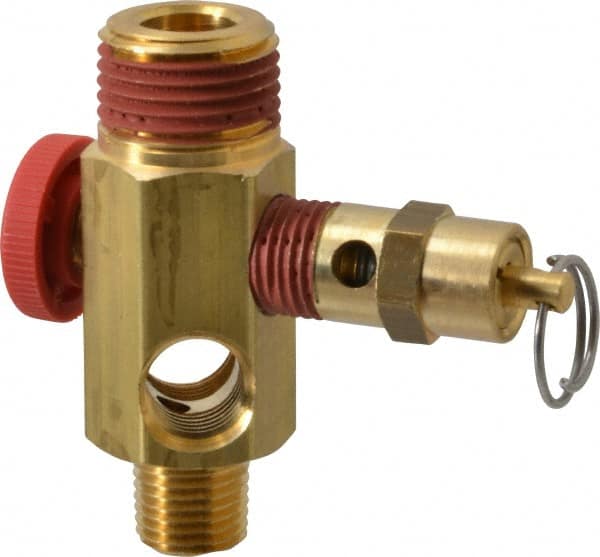

- Drain Valves: Remove excess moisture and condensation from the air.

Typical Characteristics

- Material: Accessories are constructed from materials resistant to corrosion and wear.

- Compatibility: Designed to work with a range of air compressor models.

- Easy Installation: Most accessories are easy to install and maintain.

- Customization: Allows you to tailor your compressor system to your needs.

4. Air Compressor Oil

Overview

Air compressor oil is specially formulated to lubricate and cool the compressor's internal components. Proper lubrication is vital for the longevity and performance of your air compressor.

Top 5 Applications

- Compressor Lubrication: Keeps moving parts lubricated to reduce wear and heat.

- Prevents Rust: Protects against corrosion and rust formation inside the compressor.

- Enhances Efficiency: Proper lubrication ensures the compressor operates at peak efficiency.

- Reduces Maintenance: Regular oil changes prolong the life of the compressor.

- Noise Reduction: Lubrication helps reduce friction and noise during operation.

Typical Characteristics

- Viscosity Grade: Varies depending on the compressor type and operating conditions.

- Oil Type: Mineral, synthetic, or semi-synthetic oils are available.

- Packaging: Comes in different container sizes, from quarts to gallons.

- Compatibility: Ensure the oil is compatible with your compressor's requirements.

5. Air Compressor Penetrants and Lubricants

Overview

Penetrants and lubricants designed for air compressors play a vital role in maintaining the system's integrity. They help prevent rust, reduce friction, and ensure smooth operation.

Top 5 Applications

- Prevent Corrosion: Lubricants protect compressor components from rust and corrosion.

- Extend Lifespan: Regular lubrication reduces wear and extends the compressor's life.

- Improve Efficiency: Lubricants minimize friction, enhancing overall efficiency.

- Silence Operation: Reduces noise by eliminating squeaks and creaks.

- Ensure Smooth Startup: Lubricants help prevent startup issues due to component sticking.

Typical Characteristics

- Lubrication Type: Available as oils, greases, and specialized lubricants.

- Temperature Range: Some lubricants are designed for specific temperature conditions.

- Application Method: Aerosol sprays, tubes, and cans for easy application.

- Compatibility: Ensure compatibility with your air compressor model.

6. Air Compressor Protective Covers

Overview

Protective covers for air compressors are essential for shielding your equipment from dust, debris, and the elements. They help maintain the compressor's performance and prolong its life.

Top 5 Applications

- Dust and Debris Protection: Prevents dust and debris buildup on the compressor.

- Weather Resistance: Shields the compressor from rain, snow, and UV rays.

- Outdoor Storage: Ideal for compressors stored outdoors or in harsh environments.

- Long-Term Storage: Protects compressors during extended periods of inactivity.

- Aesthetic Appeal: Enhances the appearance of your compressor setup.

Typical Characteristics

- Material: Made from durable, weather-resistant materials.

- Design: Custom-fit or universal covers available.

- Fastening: Elastic bands, zippers, or drawstrings for secure attachment.

- Ventilation: Some covers have ventilation to prevent condensation.

7. Air Compressor System Controller

Overview

Air compressor system controllers are advanced devices that manage and optimize the operation of your compressor system. They help ensure energy efficiency and performance.

Top 5 Applications

- Energy Efficiency: Controllers optimize compressor operation to reduce energy consumption.

- Pressure Control: Maintain precise air pressure levels for specific applications.

- Remote Monitoring: Some controllers offer remote monitoring and control capabilities.

- Fault Detection: Detect and diagnose system issues for timely maintenance.

- Data Logging: Collect and analyze performance data for system optimization.

Typical Characteristics

- Control Type: Can be simple on/off controllers or advanced digital systems.

- Connectivity: Ethernet, Wi-Fi, or cellular connectivity for remote access.

- User Interface: Touchscreens or digital displays for easy configuration.

- Compatibility: Controllers are designed for specific compressor models.

8. Stationary Air Compressor Accessories

Overview

Stationary air compressors have specific accessory needs. These accessories enhance their performance and convenience in industrial and commercial settings.

Top 5 Accessories

- Receiver Tanks: Increase air storage capacity for peak demand periods.

- Air Dryers: Remove moisture from compressed air to prevent damage to tools and equipment.

- Air Filters: Ensure clean and dry air for sensitive applications.

- Pressure Switches: Control and maintain desired air pressure levels.

- Piping and Fittings: Quality piping and fittings ensure efficient air distribution.

Typical Characteristics

- Accessory Type: Varied, depending on the specific accessory category.

- Material: High-quality materials for durability.

- Compatibility: Accessories designed to work seamlessly with stationary compressors.

- Installation: Some accessories may require professional installation.

9. Air Compressors and Vacuum Pumps

Overview

Air compressors and vacuum pumps are versatile machines used in various industries for generating compressed air or creating a vacuum. They come in different types and sizes to suit diverse applications.

Top 5 Applications

- Industrial Manufacturing: Compressed air powers tools and machinery.

- Construction: Used for pneumatic tools and equipment on job sites.

- Medical Devices: Provide vacuum for medical instruments and procedures.

- Automotive: Used in auto repair shops for pneumatic tools and tire inflation.

- Food Processing: Compressors help with packaging and processing.

Typical Characteristics

- Type: Reciprocating, rotary screw, centrifugal, or vacuum pumps.

- Power Source: Electric, gas, or diesel engines.

- Tank Size: Varies from small portable tanks to large industrial ones.

- CFM (Cubic Feet per Minute): Determines air output capacity.

- Pressure Rating: Indicates maximum air pressure generated.

10. Air Compressor Pumps

Overview

Air compressor pumps are the heart of any air compression system. They come in various types, and choosing the right pump is crucial for optimal performance.

Top 5 Applications

- Industrial Use: Power pneumatic tools, machinery, and equipment.

- Home Garage: Run air tools for DIY projects and car maintenance.

- Construction: Power nail guns, sanders, and paint sprayers on job sites.

- Automotive Shops: Inflating tires and operating air tools.

- HVAC Systems: Provide compressed air for heating and cooling systems.

Typical Characteristics

- Type: Single-stage, two-stage, or rotary screw pumps.

- Horsepower: Determines the pump's power output.

- Oil-Lubricated or Oil-Free: Oil-free pumps are low-maintenance.

- Tank Size: Pumps can be mounted on tanks for additional air storage.

11. Gas Engine Air Compressor Combination Units

Overview

Gas engine air compressor combination units provide the convenience of a portable power source and compressed air in one package. They are commonly used in remote or outdoor settings.

Top 5 Applications

- Construction Sites: Provide power and compressed air for tools.

- Agriculture: Run pneumatic equipment in the field.

- Off-Roading: Inflating tires and running air tools on off-road trips.

- Emergency Backup: Backup power and air supply during outages.

- Outdoor Events: Ideal for powering equipment at festivals and fairs.

Typical Characteristics

- Engine Type: Gasoline or diesel engines.

- Air Compressor Type: Single-stage or two-stage.

- Portability: Equipped with wheels for easy transport.

- Tank Capacity: Varies based on the unit's size and purpose.

12. Laboratory Air Compressors

Overview

Laboratory air compressors are designed for precision and reliability, making them suitable for scientific and research applications. They provide clean and oil-free compressed air.

Top 5 Applications

- Scientific Research: Power laboratory equipment and experiments.

- Medical Laboratories: Supply clean compressed air for medical devices.

- Pharmaceuticals: Used in pharmaceutical production processes.

- Quality Control: Ensure precise air pressure for testing and calibration.

- Dental Clinics: Provide compressed air for dental tools and equipment.

Typical Characteristics

- Oil-Free: These compressors are oil-free to maintain air purity.

- Quiet Operation: Designed for minimal noise in laboratory environments.

- Precision Control: Ensure accurate air pressure regulation.

- Compact Design: Space-saving and suitable for laboratory settings.

13. Piston Air Compressors and Vacuum Pumps

Overview

Piston air compressors and vacuum pumps are versatile machines used in various applications. They are known for their durability and reliability.

Top 5 Applications

- Auto Repair Shops: Power pneumatic tools and tire inflation.

- Woodworking: Run nail guns, sanders, and paint sprayers.

- Manufacturing: Supply compressed air for assembly lines and machinery.

- Dental Clinics: Provide clean and dry compressed air for dental tools.

- Medical Equipment: Used in medical devices and laboratory equipment.

Typical Characteristics

- Single or Two-Stage: Offered in single or two-stage configurations.

- Tank Size: Varies from small portable tanks to larger ones for industrial use.

- Power Source: Electric or gas engines.

- Maintenance: Some models require regular oil changes.

14. Portable Electric Air Compressors

Overview

Portable electric air compressors are convenient and versatile tools suitable for various applications, from DIY projects to professional use.

Top 5 Applications

- DIY Enthusiasts: Power pneumatic tools for home projects.

- Tire Inflation: Easily inflate car and bicycle tires.

- Outdoor Sports: Inflate sports equipment like basketballs and soccer balls.

- Camping: Run air mattresses and inflate camping gear.

- Light Construction: Suitable for small construction tasks.

Typical Characteristics

- Portability: Compact and lightweight for easy transport.

- Tank Size: Varies from small tanks for portability to larger ones for more air capacity.

- Power Source: Electric, making them suitable for indoor and outdoor use.

- Pressure Output: Adequate pressure for various applications.

15. Portable Gas Engine Air Compressors

Overview

Portable gas engine air compressors are ideal for remote locations and outdoor applications where electrical power may not be readily available.

Top 5 Applications

- Construction Sites: Power pneumatic tools in remote areas.

- Agriculture: Run air tools and equipment in the field.

- Off-Roading: Inflating large tires on off-road vehicles.

- Emergency Backup: Provide compressed air and power during outages.

- Outdoor Events: Run equipment at festivals and outdoor gatherings.

Typical Characteristics

- Gasoline or Diesel Engines: Reliable power sources for remote use.

- Portability: Equipped with wheels and handles for easy transport.

- Tank Size: Varies based on the unit's size and intended use.

- Pressure Output: Adequate for various pneumatic tools.

16. Rotary Screw Air Compressors

Overview

Rotary screw air compressors are powerful and efficient machines commonly used in industrial and commercial settings for continuous compressed air supply.

Top 5 Applications

- Manufacturing Plants: Power pneumatic machinery and assembly lines.

- Automotive Manufacturing: Use for painting, welding, and more.

- Medical Facilities: Provide compressed air for medical devices.

- Food Processing: Used for packaging and production.

- Oil and Gas Industry: Support drilling and pneumatic tools.

Typical Characteristics

- Type: Rotary screw compressors with twin screws for air compression.

- Capacity: Suitable for high-demand applications.

- Energy Efficiency: Designed for efficient, continuous operation.

- Maintenance: Regular maintenance is essential for optimal performance.

17. Stationary Electric Air Compressors

Overview

Stationary electric air compressors are designed for heavy-duty, continuous use in industrial settings. They provide a reliable source of compressed air.

Top 5 Applications

- Manufacturing Facilities: Power machinery and pneumatic tools.

- Auto Repair Shops: Operate a wide range of air-powered tools.

- Construction Sites: Support various construction equipment.

- Large-scale Production: Ideal for high-demand applications.

- Energy Plants: Provide compressed air for power generation.

Typical Characteristics

- Electric Motor: Reliable power source for continuous operation.

- Tank Size: Large tanks for ample air storage.

- High CFM Output: Capable of meeting heavy air demands.

- Industrial-Grade: Designed for durability and performance.

18. Stationary Gas Engine Air Compressors

Overview

Stationary gas engine air compressors provide reliable compressed air in locations without access to electricity. They are commonly used in remote industrial settings.

Top 5 Applications

- Oil and Gas Exploration: Support drilling operations.

- Mining: Power pneumatic tools for mining operations.

- Agriculture: Run air equipment in rural areas.

- Construction: Compressed air for construction sites without power.

- Emergency Backup: Provide backup power and compressed air.

Typical Characteristics

- Gasoline or Diesel Engines: Reliable power sources.

- Large Tanks: For extended use in remote locations.

- Heavy-Duty Construction: Designed for rugged environments.

- Versatile Use: Suitable for various industrial applications.

19. Air Compressor Separator Kits

Overview

Air compressor separator kits are essential for maintaining clean and efficient compressed air systems. They remove moisture and contaminants from the air.

Top 5 Applications

- Industrial Manufacturing: Ensure clean and dry compressed air for production.

- Automotive Painting: Prevent moisture and particles in paint applications.

- Medical and Pharmaceutical: Maintain air purity for critical processes.

- Food and Beverage: Keep compressed air free from contaminants.

- Instrumentation: Ensure precise air quality for testing and calibration.

Typical Characteristics

- Filter Type: Different kits include coalescing and particulate filters.

- Size: Various sizes to match different compressor systems.

- Installation: Professional installation may be required.

- Maintenance: Regular filter replacement is essential.

20. Air Compressor & Vacuum Pump Accessories

Overview

Air compressor and vacuum pump accessories enhance the functionality and efficiency of these machines. They include various components and parts.

Top 5 Accessories

- Air Hoses: Connect compressors to pneumatic tools.

- Pressure Regulators: Control air pressure for specific applications.

- Filters and Lubricators: Maintain air quality and compressor health.

- Fittings and Couplers: Connect hoses and tools securely.

- Replacement Parts: Ensure smooth operation with spare components.

Typical Characteristics

- Compatibility: Accessories are designed to fit specific compressor models.

- Materials: Durable materials for long-lasting performance.

- Easy Installation: Most accessories are user-installable.

- Regular Maintenance: Keep accessories in good condition for optimal results.

21. Air Compressor Repair Kits

Overview

Air compressor repair kits contain essential components for repairing and maintaining your compressor, extending its lifespan and efficiency.

Top 5 Components

- Gaskets and Seals: Prevent air leaks and maintain compression.

- Valve Kits: Replace worn or damaged valves for proper operation.

- Piston Rings: Ensure airtight seals within the compressor.

- Oil and Lubricants: Keep moving parts well-lubricated.

- Filters and Belts: Replace worn-out filters and belts for efficiency.

Typical Characteristics

- Compatibility: Kits are designed for specific compressor models.

- Easy Installation: Components come with clear installation instructions.

- Regular Maintenance: Proper maintenance ensures compressor longevity.

- Cost-Effective: Repairing is often more cost-effective than replacement.

22. Air Compressors

Overview

Air compressors come in various types and sizes to cater to different applications. Choosing the right compressor is essential for efficiency and performance.

Top 5 Applications

- Industrial Use: Power machinery, tools, and equipment.

- Construction: Run pneumatic tools on job sites.

- Automotive Repair: Inflating tires and operating air tools.

- Manufacturing: Supply compressed air for production lines.

- Home Use: For DIY projects, painting, and inflation.

Typical Characteristics

- Type: Reciprocating, rotary screw, centrifugal, or others.

- Power Source: Electric, gas, or diesel engines.

- Tank Size: Varies from small portable tanks to large industrial ones.

- CFM (Cubic Feet per Minute): Determines air output capacity.

- Pressure Rating: Indicates maximum air pressure generated.

23. Supplied Air Compressors and Ambient Air Pumps

Overview

Supplied air compressors and ambient air pumps are critical for providing clean and breathable air in hazardous environments.

Top 5 Applications

- Hazardous Jobs: Protect workers in environments with low oxygen or contaminants.

- Confined Spaces: Ensure air supply in tight and enclosed work areas.

- Chemical Handling: Prevent exposure to harmful gases.

- Emergency Response: Provide clean air in rescue operations.

- Industrial Safety: Essential in safety programs and compliance.

Typical Characteristics

- Portable: Designed for easy transport to job sites.

- Filtering: Filters and purifies incoming air.

- Airflow Rate: Provides a sufficient supply of clean air.

- Safety Features: Equipped with alarms and gauges for monitoring.

This comprehensive guide has covered a wide range of air compressors and accessories, helping you make informed decisions when purchasing these essential tools and equipment. Whether you're a professional in an industrial setting or a DIY enthusiast working on home projects, understanding the various types and applications of air compressors is key to achieving your goals efficiently and effectively. Make sure to explore the specific categories and products that match your needs on GoVets.com to find the perfect fit for your requirements.

Top 10 Signs That Your Air Compressor Needs Maintenance or Component Repairs

- Decreased Performance: If you notice a drop in the performance of your air compressor, such as reduced air pressure or slower operation, it's a clear sign that maintenance is required. This could be due to worn-out components like valves or pistons.

- Unusual Noises: Unusual or loud noises coming from the compressor, such as knocking or hissing sounds, can indicate issues with internal components. These noises may be a sign of leaks or worn parts.

- Leakage: Any visible air or oil leaks from the compressor are definite red flags. Leaks not only waste energy but also indicate potential problems with seals, fittings, or hoses that need attention.

- Excessive Heat: If your compressor becomes unusually hot during operation, it could signify problems with cooling mechanisms or inadequate lubrication. Overheating can lead to component failure.

- Inconsistent Pressure: Fluctuations in air pressure can be frustrating and are often a sign of pressure switch problems or air leaks within the system.

- Longer Run Cycles: If your compressor runs for extended periods to reach the desired pressure, it may be struggling due to issues with valves, air filters, or the motor.

- Oil Contamination: If you have an oil-lubricated compressor and notice that the discharged air contains oil mist or particles, it's an indication that the oil separator or filters need replacement.

- Frequent Tripping: Frequent trips of the motor overload or circuit breaker are a clear sign of electrical issues or motor problems. This should be addressed promptly to avoid motor burnout.

- Visible Wear: Visual inspection is crucial. If you see signs of wear, corrosion, or damage on critical components like belts, hoses, or pulleys, it's time for replacements.

- High Moisture Content: If the compressed air contains excessive moisture, it can damage downstream equipment and lead to corrosion. This suggests problems with the air dryer or moisture separator.

Addressing these signs promptly through regular maintenance can extend the lifespan of your air compressor and ensure it operates efficiently.

Top 10 Signs That Your Air Compressor Needs to Be Replaced

- Age: The age of your air compressor matters. If it's approaching the end of its expected lifespan, investing in a new one might be more cost-effective than frequent repairs.

- Frequent Breakdowns: If your compressor requires frequent repairs, it may be a sign that it's becoming unreliable and inefficient. Frequent downtime can impact productivity.

- Obsolete Technology: Older compressors may lack energy-efficient features and the latest technology. Upgrading to a newer model can result in energy savings and improved performance.

- Inadequate Capacity: If your current compressor can't meet your growing air demands, it's time for an upgrade. Running a compressor beyond its capacity can lead to premature wear.

- High Energy Consumption: Energy-efficient compressors have become the norm. If your compressor is consuming excessive energy, replacing it with a more efficient model can reduce operating costs.

- Lack of Spare Parts: If it's challenging to find spare parts for your old compressor due to discontinuation, it's a strong indicator that replacement is necessary.

- Low Air Quality: If your compressor struggles to maintain clean, dry air, it can affect product quality and damage downstream equipment. Newer models offer better air treatment capabilities.

- Safety Concerns: Older compressors may lack modern safety features. If safety is a concern in your facility, upgrading to a compressor with advanced safety measures is advisable.

- Increased Noise: Older compressors tend to be noisier. If noise levels are a concern for your workspace, a quieter and more modern compressor is a sensible choice.

- Environmental Regulations: Newer compressors often comply with stricter environmental regulations. Upgrading can help ensure compliance and reduce environmental impact.

When considering replacement, it's essential to assess your current needs, budget, and the available options to choose the most suitable compressor for your application.

History of Air Compressors

The history of air compressors is a fascinating journey that stretches back through the annals of time. It's a story of human ingenuity, innovation, and the relentless pursuit of harnessing the power of compressed air for a myriad of applications. Let's embark on this historical voyage, exploring the origins and evolution of air compressors over the centuries.

Ancient Origins:

Our tale begins in ancient civilizations, where rudimentary tools were employed to generate compressed air. Among the earliest known uses of compressed air was the creation of fire. Imagine ancient Egyptians and Greeks, wielding bellows, which were essentially air pumps, to blow air into a fire. This seemingly simple act had a profound impact, intensifying flames and serving as an early display of the potential of compressed air.

The Industrial Revolution:

The true journey of air compressors, however, gained momentum during the Industrial Revolution in the 18th century. This period of technological upheaval witnessed inventors and engineers actively seeking ways to harness the power of compressed air for an array of industrial applications. It was an era marked by the pursuit of efficiency, and air compressors were poised to play a pivotal role.

George Medhurst's Innovation:

In 1799, a significant milestone was reached when George Medhurst unveiled his pioneering invention – the air compressor. Medhurst's contraption employed a water-wheel-driven air pump to compress air, which was then stored in a reservoir. This innovation marked a critical turning point in the development of air compressors and laid the foundation for the modern machines we rely on today.

The 19th Century Advances:

The 19th century witnessed a flurry of advancements in air compressor technology. Notably, the introduction of piston compressors and rotary screw compressors heralded a new era of efficiency and versatility. These machines found applications in factories, mines, and workshops, driving various industrial processes with their reliable and consistent output.

The 20th Century Boom:

As the 20th century dawned, the demand for compressed air surged dramatically. Air compressors transitioned from being niche tools to becoming integral components of various industries. They powered pneumatic tools, ensuring that construction sites hummed with productivity. In healthcare, air compressors played a vital role in medical equipment like ventilators, highlighting their significance in saving lives.

Today's Diversity:

Fast forward to the present day, and air compressors have evolved into a diverse array of types and sizes, tailored to meet the demands of a wide range of applications. From compact and portable compressors suitable for household tasks to colossal industrial compressors capable of supplying air to entire factories, the scope of their utility has never been broader.

The history of air compressors is not just a tale of technological advancement; it's a testament to human curiosity and the relentless pursuit of progress. As industries continue to evolve and diversify, air compressors stand ready to adapt, providing the vital compressed air that powers our modern world. Their journey is far from over, as they continue to propel us forward into an era of innovation and efficiency.

How Air Compressors Work

Air compressors are ingenious devices that convert power, typically from an electric motor or a combustion engine, into compressed air. This compressed air can then be used for a wide range of applications across various industries. Understanding how air compressors work is essential for appreciating their versatility and importance in our modern world.

The Basic Operation:

At its core, an air compressor operates on a simple principle: it draws in air from the surrounding environment and compresses it to increase its pressure. This compressed air is then stored in a tank or used directly for various tasks.

The key components of an air compressor include:

- Air Intake: Air compressors have an intake valve or filter that draws in atmospheric air.

- Compression Chamber: Once the air is inside, it enters a compression chamber where the magic happens. Here, the air is squeezed into a smaller volume, which increases its pressure. This is typically done using a piston or a rotating screw mechanism.

- Storage Tank: In many cases, the compressed air is stored in a tank, which acts as a reservoir. This allows for a steady supply of compressed air even when the compressor is not actively running.

- Pressure Regulator: Air compressors often feature a pressure regulator that allows users to adjust the output pressure as needed for specific applications.

The Compression Process:

Let's take a closer look at the compression process, which is the heart of any air compressor:

- Intake: The compressor's intake valve or filter draws in ambient air. This air contains a mixture of gases, primarily nitrogen and oxygen.

- Compression: Inside the compression chamber, the air is subjected to high pressure. If it's a reciprocating piston compressor, the piston moves downward, reducing the volume of the chamber and compressing the air. If it's a rotary screw compressor, two interlocking helical screws compress the air as they rotate. As the volume decreases, the pressure increases significantly.

- Heat Generation: Compressing air generates heat due to the increased pressure. This heat is typically removed using a cooling system to prevent overheating of the compressor.

- Storage: Once compressed, the air is stored in a tank. The tank allows for a steady supply of compressed air even when the compressor is not actively running. It also helps smooth out pressure fluctuations.

Applications of Compressed Air:

Compressed air is incredibly versatile and finds application in various industries and tasks, including:

- Pneumatic Tools: One of the most common uses is powering pneumatic tools like impact wrenches, nail guns, and paint sprayers. The high-pressure air allows these tools to perform tasks efficiently.

- Industrial Processes: Compressed air is used in manufacturing processes, such as packaging, labeling, and material handling. It's also vital in controlling pneumatic systems in machinery.

- Construction: Air compressors power jackhammers, sandblasters, and concrete vibrators on construction sites.

- HVAC Systems: Air compressors are used in air conditioning and refrigeration systems for cooling and refrigerant circulation.

- Medical Equipment: Compressed air plays a critical role in medical devices like ventilators and dental equipment.

- Aerospace: In the aerospace industry, compressed air is used for cabin pressurization, aircraft braking systems, and pneumatic actuators.

Understanding how air compressors work provides a foundation for using them effectively and maintaining them for optimal performance. Whether you're a professional relying on compressed air in your work or simply interested in the mechanics behind these machines, the knowledge of their operation is both fascinating and practical.

Conclusions

In this comprehensive exploration of air compressors and winches, we've delved into the intricacies of these versatile tools that have shaped industries and powered countless applications. From their historical origins to practical applications, maintenance considerations, and the signs that indicate when it's time for maintenance or replacement, we've covered a wide spectrum of information to help consumers make informed decisions.

Air compressors, with their rich history dating back to ancient civilizations, have come a long way, evolving into a diverse array of machines that cater to the needs of modern industries. Their journey showcases human ingenuity and the constant quest for innovation, with each era contributing to the development of more efficient and versatile compressors.

On the other hand, winches, often underappreciated but indispensable, serve diverse roles in lifting, pulling, and securing loads. We've explored their various types and applications, highlighting their critical roles in industries ranging from construction and marine operations to theatre rigging and cable pulling.

Understanding the signs that indicate maintenance or replacement is crucial for ensuring the longevity and efficiency of these tools. Knowing when to address issues can prevent costly breakdowns and downtime, keeping operations running smoothly.

As we wrap up this informative journey, one thing is clear: both air compressors and winches are integral components of various industries and applications. Whether you're considering a new purchase, conducting maintenance, or evaluating signs of wear and tear, the knowledge gained here can serve as a valuable resource for making informed decisions.

In the ever-evolving landscape of technology and industry, these tools continue to adapt, proving their resilience and importance. As we look ahead, it's certain that air compressors and winches will remain steadfast allies in powering our world, both in the workplace and at home.