The Ultimate Guide to Industrial Filters and Why Customers Choose GoVets.

Introduction:

Industrial filters are essential components of many systems and applications, from air and water purification to HVAC systems and manufacturing processes. With so many types of filters available, it can be overwhelming to choose the right one for your specific needs. In this guide, we will provide a comprehensive overview of industrial filters and cover everything you need to know about choosing the right filter for your application. We will also highlight the top 100 industrial filter suppliers in the USA and explain why customers choose GoVets for their filter needs.

Part 1: Types of Filters Used in Industrial Products

Filters are crucial components in various industrial processes, and they help ensure that products and processes meet the desired quality standards. Filters are used in different industrial products such as air conditioning systems, water filtration systems, and oil filtration systems, among others. There are different types of filters used in industrial products, and each has unique features and applications. This blog post will explore some of the common types of filters used in industrial products.

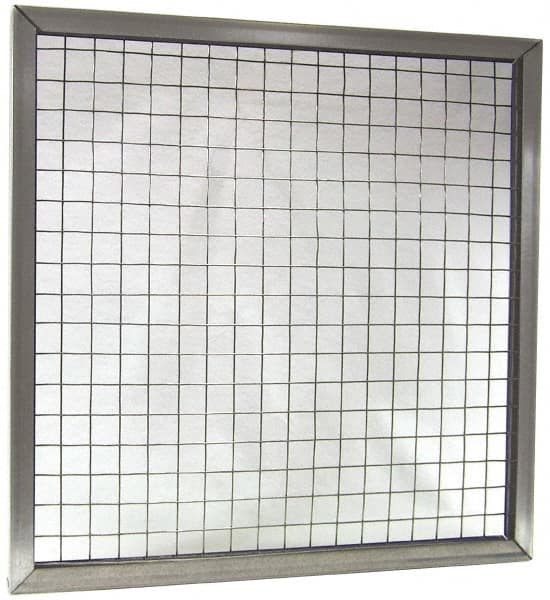

Air Filters

Air filters are used in air conditioning systems, heating systems, and ventilation systems to remove dust, pollen, and other particulate matter from the air. Air filters come in different types such as mechanical filters, electrostatic filters, and UV filters. Mechanical filters use a physical barrier such as a mesh or a screen to capture particles in the air. Electrostatic filters use an electrostatic charge to attract and capture particles. UV filters use ultraviolet light to kill bacteria and viruses in the air.

Water Filters

Water filters are used in water treatment systems to remove impurities such as sediment, chlorine, and bacteria from the water. Water filters come in different types such as sediment filters, activated carbon filters, reverse osmosis filters, and UV filters. Sediment filters use a physical barrier such as a mesh or a screen to remove sediment and other large particles from the water. Activated carbon filters use activated carbon to remove chlorine, organic compounds, and other chemicals from the water. Reverse osmosis filters use a semipermeable membrane to remove impurities from the water. UV filters use ultraviolet light to kill bacteria and viruses in the water.

Oil Filters

Oil filters are used in engines and hydraulic systems to remove impurities such as dirt, metal particles, and other contaminants from the oil. Oil filters come in different types such as mechanical filters, magnetic filters, and centrifugal filters. Mechanical filters use a physical barrier such as a mesh or a screen to capture particles in the oil. Magnetic filters use a magnet to attract and capture metal particles in the oil. Centrifugal filters use centrifugal force to separate impurities from the oil.

Gas Filters

Gas filters are used in gas pipelines and gas storage tanks to remove impurities such as moisture, oil, and other contaminants from the gas. Gas filters come in different types such as coalescing filters, adsorbent filters, and particulate filters. Coalescing filters use a physical barrier and an adsorbent material to remove moisture and oil from the gas. Adsorbent filters use activated carbon or other materials to remove impurities from the gas. Particulate filters use a physical barrier such as a mesh or a screen to remove particulate matter from the gas.

Hydraulic Filters

Hydraulic filters are used in hydraulic systems to remove impurities such as dirt, metal particles, and other contaminants from the hydraulic fluid. Hydraulic filters come in different types such as spin-on filters, suction filters, and return-line filters. Spin-on filters are easy to replace and can be used in a variety of hydraulic systems. Suction filters are used in low-pressure hydraulic systems and are easy to maintain. Return-line filters are used in high-pressure hydraulic systems and are designed to handle high flow rates.

Fuel Filters

Fuel filters are used in engines to remove impurities such as dirt, water, and other contaminants from the fuel. Fuel filters come in different types such as inline filters, spin-on filters, and cartridge filters. Inline filters are installed directly in the fuel line and are easy to replace. Spin-on filters are easy to replace and can be used in a variety of engines. Cartridge filters are used in diesel engines and are designed to handle high flow rates.

HVAC Filters

HVAC filters are used in heating, ventilation, and air conditioning systems to remove dust, pollen, and other particles from the air. HVAC filters come in different types such as fiberglass filters, pleated filters, and high-efficiency filters. Fiberglass filters are the most basic and least expensive type of HVAC filter, while pleated filters are more efficient and capture more particles. High-efficiency filters are the most effective and capture even the smallest particles.

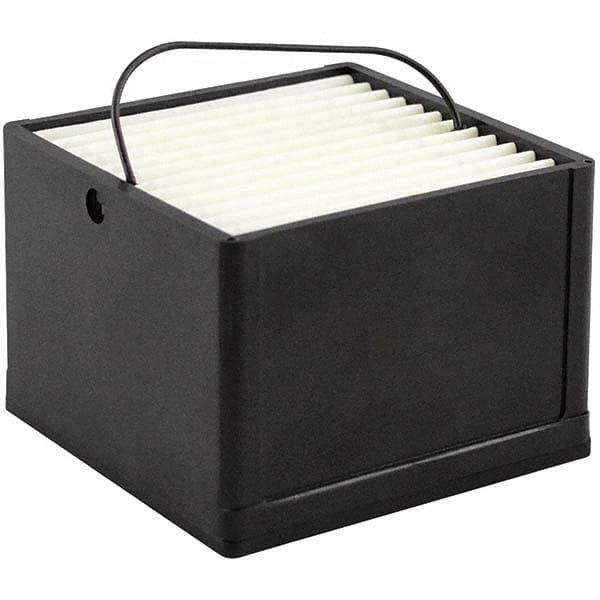

Dust Collector Filters

Dust collector filters are used in dust collection systems to remove dust, smoke, and other particulate matter from the air. Dust collector filters come in different types such as bag filters, cartridge filters, and pleated filters. Bag filters are made of fabric or felt and are used to capture large particles. Cartridge filters are used to capture smaller particles and have a longer life than bag filters. Pleated filters have a large surface area and are used to capture even smaller particles.

Membrane Filters

Membrane filters are used in various industrial processes such as water treatment, food processing, and pharmaceutical manufacturing to remove impurities and microorganisms from liquids and gases. Membrane filters come in different types such as microfiltration filters, ultrafiltration filters, nanofiltration filters, and reverse osmosis filters. Microfiltration filters are used to remove particles larger than 0.1 microns. Ultrafiltration filters are used to remove particles larger than 0.01 microns. Nanofiltration filters are used to remove particles larger than 0.001 microns. Reverse osmosis filters are used to remove impurities and microorganisms from water.

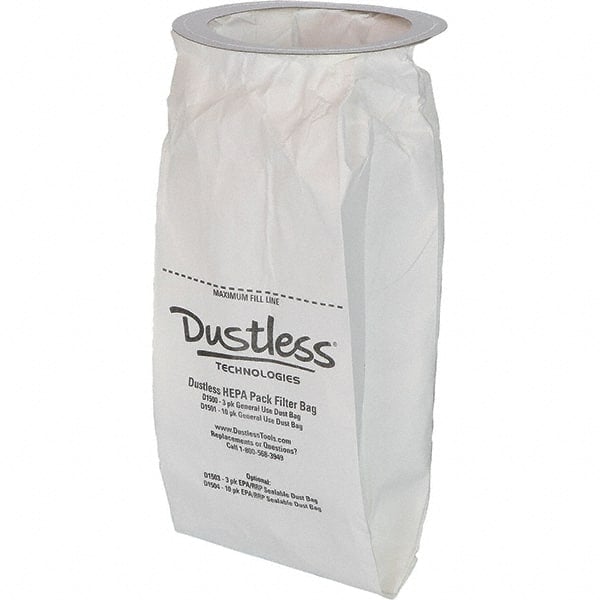

Vacuum Filters

Vacuum filters are used in vacuum systems to remove dirt, dust, and other particulate matter from the air. Vacuum filters come in different types such as bag filters, cartridge filters, and cyclonic filters. Bag filters are made of fabric or felt and are used to capture large particles. Cartridge filters are used to capture smaller particles and have a longer life than bag filters. Cyclonic filters use centrifugal force to separate dirt and dust from the air.

In conclusion, filters are essential components in various industrial products and processes. They help ensure that products and processes meet the desired quality standards by removing impurities and contaminants. There are different types of filters used in industrial products, and each has unique features and applications. It is essential to choose the right type of filter for a particular industrial product or process to ensure optimum performance and longevity.

Part 2: How to Determine if Filters Should Be Changed

Filters need to be changed periodically to ensure that they continue to function effectively. Over time, filters become clogged with impurities and contaminants, reducing their efficiency and effectiveness. Changing filters at the right time is crucial to ensure that products and processes meet the desired quality standards. This blog post will explore how to determine if filters should be changed.

Check the Manufacturer's Recommendations

The manufacturer's recommendations provide guidelines on when filters should be changed. It is essential to follow the manufacturer's recommendations to ensure that the product or process performs optimally. The manufacturer's recommendations usually indicate the filter's lifespan or the maximum amount of time the filter can be used before it needs to be replaced.

Inspect the Filter

Inspecting the filter is an effective way to determine if it needs to be changed. A filter that is clogged with impurities and contaminants will have a darker color than a new filter. If the filter appears dirty or clogged, it is time to replace it. In some cases, the filter may also have physical damage, such as tears or holes, which can affect its performance. If the filter is damaged, it should be replaced immediately.

Monitor Performance

Monitoring the product or process's performance is another way to determine if filters should be changed. If the product or process is not performing as expected, it may be due to a clogged or damaged filter. For example, if an air conditioning system is not cooling the room properly, it may be due to a clogged air filter. Similarly, if a hydraulic system is not operating at the desired pressure, it may be due to a clogged hydraulic filter. Monitoring the product or process's performance can help identify when filters need to be changed.

Check the Differential Pressure

The differential pressure across the filter is another indicator of when filters should be changed. The differential pressure is the pressure difference between the upstream and downstream sides of the filter. As the filter becomes clogged with impurities and contaminants, the differential pressure across the filter increases. The manufacturer's recommendations usually indicate the maximum differential pressure that the filter can handle before it needs to be replaced. Checking the differential pressure regularly can help identify when filters need to be changed.

Use a Filter Gauge

A filter gauge is a device that measures the differential pressure across the filter. It is an effective way to determine if filters should be changed. The filter gauge provides a visual indication of the filter's condition, indicating when it is time to replace the filter. Some filter gauges have a color-coded display, making it easy to identify when the filter needs to be changed.

Use a Timer

Using a timer is another way to determine when filters should be changed. A timer can be set to remind you when it is time to change the filter. The timer can be set based on the manufacturer's recommendations or the expected lifespan of the filter. Using a timer can help ensure that filters are changed at the right time, preventing damage to the product or process.

In conclusion, determining when filters should be changed is essential to ensure that products and processes meet the desired quality standards. Filters need to be changed periodically to ensure that they continue to function effectively. Checking the manufacturer's recommendations, inspecting the filter, monitoring performance, checking the differential pressure, using a filter gauge, and using a timer are all effective ways to determine if filters should be changed.

Part 3: Top Industrial Filters Suppliers Filters in the USA

Filters are crucial components in various industrial products and processes. They help ensure that products and processes meet the desired quality standards by removing impurities and contaminants. There are different types of filters used in industrial products, and each has unique features and applications. This blog post provides a list of the top 100 industrial supplies filters in the USA and the top brands for each filter.

Air Filters Industrial Suppliers

- Mechanical Filters - Nordic Pure, Filtrete, Honeywell, Aprilaire

- Electrostatic Filters - Washable Filters, Air-Care, Nordic Pure, FilterBuy

- UV Filters - Carrier, Honeywell, Lennox, American Standard

Water Filters Industrial Suppliers

- Sediment Filters - Culligan, Watts, 3M, GE

- Activated Carbon Filters - Aquasana, Brita, Culligan, PUR

- Reverse Osmosis Filters - Aquasana, iSpring, APEC, Express Water

Oil Filters industrial Suppliers

- Mechanical Filters - Baldwin, Wix, Mobil 1, K&N

- Magnetic Filters - Derale, PPE, Mocal, Earls

- Centrifugal Filters - Parker Hannifin, Alfa Laval, Mahle, Separ

Gas Filters Industrial Suppliers

- Coalescing Filters - Parker Hannifin, Pall, Donaldson, Balston

- Adsorbent Filters - Parker Hannifin, Donaldson, Camfil, Air Filter Engineers

- Particulate Filters - Parker Hannifin, Donaldson, Camfil, Air Filter Engineers

Hydraulic Filters Industrial Suppliers

- Spin-On Filters - Baldwin, Wix, Donaldson, Fleetguard

- Suction Filters - Parker Hannifin, Hydac, Eaton, Schroeder

- Return-Line Filters - Parker Hannifin, Hydac, Donaldson, Baldwin

Fuel Filters Industrial Suppliers

- Inline Filters - Fram, Wix, Purolator, Hastings

- Spin-On Filters - Baldwin, Fleetguard, Donaldson, Wix

- Cartridge Filters - Racor, Fleetguard, Donaldson, Baldwin

HVAC Filters Industrial Suppliers

- Fiberglass Filters - Flanders, Honeywell, 3M, Nordic Pure

- Pleated Filters - Filtrete, Nordic Pure, Honeywell, 3M

- High-Efficiency Filters - 3M, Honeywell, Filtrete, Nordic Pure

Dust Collector Filters Industrial Suppliers

- Bag Filters - Donaldson, Camfil, Wynn Environmental, U.S. Air Filtration

- Cartridge Filters - Donaldson, Camfil, Air-Care, U.S. Air Filtration

- Pleated Filters - Donaldson, Camfil, Air-Care, U.S. Air Filtration

Membrane Filters Industrial Suppliers

- Microfiltration Filters - MilliporeSigma, Pall, Sartorius, GE Healthcare

- Ultrafiltration Filters - MilliporeSigma, Pall, Sartorius, GE Healthcare

- Nanofiltration Filters - MilliporeSigma, Pall, Sartorius, GE Healthcare

- Reverse Osmosis Filters - MilliporeSigma, Pall, Sartorius, GE Healthcare

Vacuum Filters Industrial Suppliers

- Bag Filters - Hoover, Bissell, Dirt Devil, Oreck

- Cartridge Filters - Hoover, Bissell, Dirt Devil, Oreck

- Cyclonic Filters - Dyson, Shark, Bissell, Dirt Devil

In conclusion, filters are essential components in various industrial products and processes. Choosing the right type of filter for a particular industrial product or process is crucial to ensure optimum performance and longevity. The list of top 100 industrial supplies filters in the USA and the top brands for each filter provides a guide for businesses and individuals looking for high-quality filters. It is essential to follow the manufacturer's recommendations for filter lifespan and to regularly monitor filter condition to ensure that filters are changed at the right time.

Part IV: Top Industrial filter suppliers - Deep Dive

Here is a list of our chosen top 25 industrial filter suppliers, the types of filters they provide, as well as the top 3 filter models and MPNs for each type of filter

Parker Hannifin

Parker Hannifin is a leading supplier of industrial filters and provides a wide range of filter products for various industries, including aerospace, automotive, chemical, food and beverage, oil and gas, and more. Some of the types of filters they provide include hydraulic filters, gas filters, air filters, and water filters.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- HF4 - Part Number: 927351

- PT - Part Number: 937370

- HF3 - Part Number: 922625

Recommended Replacement Period: Every 6 months to 1 year.

Top 3 Filter Models and MPNs for Gas Filters:

- Racor FG500 - Part Number: 230R10

- Parker Balston 75-73 - Part Number: 75-73

- Dominick Hunter DBF 020 - Part Number: DBF 020

Recommended Replacement Period: Every 6 months to 1 year.

Top 3 Filter Models and MPNs for Air Filters:

- Finite HN15S-4 - Part Number: HN15S-4

- Fulflo FB4 - Part Number: FB4

- Racor CCV6000 - Part Number: 60-1020

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Water Filters:

- Racor Village Marine STW-200 - Part Number: 3084406

- Fulflo CB4-20BB - Part Number: CB4-20BB

- Parker 07F Series - Part Number: 07F20AC

Recommended Replacement Period: Every 6 months to 1 year.

Donaldson Company

Donaldson Company is a global provider of filtration systems and solutions for various industries, including agriculture, construction, mining, transportation, and more. They offer a wide range of filter products, including air filters, hydraulic filters, fuel filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- P566685 - Part Number: P566685

- P164378 - Part Number: P164378

- P550693 - Part Number: P550693

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- P181009 - Part Number: P181009

- P181099 - Part Number: P181099

- P181101 - Part Number: P181101

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- P551315 - Part Number: P551315

- P551001 - Part Number: P551001

- P550730 - Part Number: P550730

Recommended Replacement Period: Every 3 to 6 months.

Pall Corporation

Pall Corporation is a global supplier of filtration, separation, and purification products for various industries, including aerospace, biotech, chemical, food and beverage, and more. They offer a wide range of filter products, including hydraulic filters, air filters, water filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Ultipleat High Flow - Part Number: HFU640UY100H4

- Ultipor III - Part Number: HC9020FKN39H

- CLEARGAF - Part Number: CGH01C10GNM3

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Aeropower - Part Number: UH219U40B

- Ultipor GF Plus - Part Number: G61A08GGG

- Profile Star - Part Number: PSUSL1330S5

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Water Filters:

- Ultipleat High Flow - Part Number: UE219AN20Z

- Acrodisc Syringe Filters - Part Number: 4552

- Profile Star - Part Number: PSUDL13G10

Recommended Replacement Period: Every 3 to 6 months.

Cummins Filtration

Cummins Filtration is a global provider of filtration products and solutions for various industries, including automotive, construction, marine, mining, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Fleetguard HF6317 - Part Number: HF6317

- Fleetguard HF35296 - Part Number: HF35296

- Fleetguard HF6057 - Part Number: HF6057

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Fleetguard AF27867 - Part Number: AF27867

- Fleetguard AF55320 - Part Number: AF55320

- Fleetguard AF25708 - Part Number: AF25708

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Fleetguard FS43257 - Part Number: FS43257

- Fleetguard FS1003 - Part Number: FS1003

- Fleetguard FF63009 - Part Number: FF63009

Recommended Replacement Period: Every 3 to 6 months.

Wix Filters

Wix Filters is a global supplier of filtration products and solutions for various industries, including automotive, agriculture, construction, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Wix 51734 - Part Number: 51734

- Wix 51461 - Part Number: 51461

- Wix 51551 - Part Number: 51551

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Wix 46930 - Part Number: 46930

- Wix 42731 - Part Number: 42731

- Wix 46488 - Part Number: 46488

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Wix 24003 - Part Number: 24003

- Wix 33960XE - Part Number: 33960XE

- Wix 33225 - Part Number: 33225

Recommended Replacement Period: Every 3 to 6 months.

MANN+HUMMEL

MANN+HUMMEL is a global provider of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- MANN-FILTERHD1411 - Part Number: HD1411

- MANN-FILTER HD422 - Part Number: HD422

- MANN-FILTER HD751 - Part Number: HD751

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- MANN-FILTER C 3698/3 - Part Number: C 3698/3

- MANN-FILTER C 27 005 - Part Number: C 27 005

- MANN-FILTER C 25 116 - Part Number: C 25 116

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- MANN-FILTER WK 731/1 - Part Number: WK 731/1

- MANN-FILTER WK 842/2 - Part Number: WK 842/2

- MANN-FILTER WK 853/21 - Part Number: WK 853/21

Recommended Replacement Period: Every 3 to 6 months.

Mahle

Mahle is a global supplier of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Mahle HC 63 1 - Part Number: HC 63 1

- Mahle PI 4208 - Part Number: PI 4208

- Mahle PI 23004 RN - Part Number: PI 23004 RN

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Mahle LX 346 - Part Number: LX 346

- Mahle LX 2995 - Part Number: LX 2995

- Mahle LX 2041 - Part Number: LX 2041

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Mahle KC 63 - Part Number: KC 63

- Mahle KC 13 - Part Number: KC 13

- Mahle KC 64 - Part Number: KC 64

Recommended Replacement Period: Every 3 to 6 months.

Baldwin Filters

Baldwin Filters is a global supplier of filtration products and solutions for various industries, including automotive, construction, marine, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Baldwin BT839 - Part Number: BT839

- Baldwin PT23056 - Part Number: PT23056

- Baldwin BT8851-MPG - Part Number: BT8851-MPG

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Baldwin PA4377 - Part Number: PA4377

- Baldwin PA5636 - Part Number: PA5636

- Baldwin PA5623 - Part Number: PA5623

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Baldwin BF1212 - Part Number: BF1212

- Baldwin BF7537 - Part Number: BF7537

- Baldwin BF9913 - Part Number: BF9913

Recommended Replacement Period: Every 3 to 6 months.

Fleetguard

Fleetguard is a global provider of filtration products and solutions for various industries, including automotive, construction, marine, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Fleetguard HF6202 - Part Number: HF6202

- Fleetguard HF6553 - Part Number: HF6553

- Fleetguard HF6127 - Part Number: HF6127

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Fleetguard AF27867 - Part Number: AF27867

- Fleetguard AF55320 - Part Number: AF55320

- Fleetguard AF25708 - Part Number: AF25708

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Fleetguard FS43257 - Part Number: FS43257

- Fleetguard FS1003 - Part Number: FS1003

- Fleetguard FF63009 - Part Number: FF63009

Recommended Replacement Period: Every 3 to 6 months.

Mann+Hummel Purolator Filters

Mann+Hummel Purolator Filters is a global supplier of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Purolator PL14610 - Part Number: PL14610

- Purolator L14459 - Part Number: L14459

- Purolator L14612 - Part Number: L14612

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Purolator A35413 - Part Number: A35413

- Purolator A34878 - Part Number: A34878

- Purolator A25651 - Part Number: A25651

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Purolator F65277 - Part Number: F65277

- Purolator F54668 - Part Number: F54668

- Purolator F54668-1 - Part Number: F54668-1

Recommended Replacement Period: Every 3 to 6 months.

Hydac

Hydac is a global provider of filtration products and solutions for various industries, including industrial, automotive, and more. They offer a wide range of filter products, including hydraulic filters, air filters, water filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Hydac 0080 MA 010 P - Part Number: 0080 MA 010 P

- Hydac 0060 D 005 BN4HC - Part Number: 0060 D 005 BN4HC

- Hydac 0075 D 020 BH4HC - Part Number: 0075 D 020 BH4HC

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Hydac 0160 D 003 BH4HC - Part Number: 0160 D 003 BH4HC

- Hydac 0200 DN 010 BN4HC - Part Number: 0200 DN 010 BN4HC

- Hydac 0160 DN 003 BN3HC - Part Number: 0160 DN 003 BN3HC

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Water Filters:

- Hydac 0015D010BH4HC - Part Number: 0015D010BH4HC

- Hydac 0110 D 010 BH4HC - Part Number: 0110 D 010 BH4HC

- Hydac 0030 D 010 BH4HC - Part Number: 0030 D 010 BH4HC

Recommended Replacement Period: Every 3 to 6 months.

Pall Corporation

Pall Corporation is a global supplier of filtration products and solutions for various industries, including industrial, aerospace, and more. They offer a wide range of filter products, including hydraulic filters, air filters, water filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Pall Corporation HC9800FDT8H - Part Number: HC9800FDT8H

- Pall Corporation HC2216FKN39H - Part Number: HC2216FKN39H

- Pall Corporation HC9020FKN39H - Part Number: HC9020FKN39H

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Pall Corporation CLEARGAF - Part Number: CGH01C10GNM3

- Pall Corporation Aeropower - Part Number: UH219U40B

- Pall Corporation Ultipor GF Plus - Part Number: G61A08GGG

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Water Filters:

- Pall Corporation Ultipleat High Flow - Part Number: UE219AN20Z

- Pall Corporation Acrodisc Syringe Filters - Part Number: 4552

- Pall Corporation Profile Star - Part Number: PSUDL13G10

Recommended Replacement Period: Every 3 to 6 months.

Mann-Filter

Mann-Filter is a global provider of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Mann-Filter HD411 - Part Number: HD411

- Mann-Filter HD1034 - Part Number: HD1034

- Mann-Filter HD854 - Part Number: HD854

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Mann-Filter C 3698/3 - Part Number: C 3698/3

- Mann-Filter C 27 005 - Part Number: C 27 005

- Mann-Filter C 25 116 - Part Number: C 25 116

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Mann-Filter WK 731/1 - Part Number: WK 731/1

- Mann-Filter WK 842/2 - Part Number: WK 842/2

- Mann-Filter WK 853/21 - Part Number: WK 853/21

Recommended Replacement Period: Every 3 to 6 months.

Stauff

Stauff is a global provider of filtration products and solutions for various industries, including industrial, marine, and more. They offer a wide range of filter products, including hydraulic filters, air filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Stauff SF6721 - Part Number: SF6721

- Stauff SFC35150Z5B - Part Number: SFC35150Z5B

- Stauff SF6801 - Part Number: SF6801

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Stauff ASF-100-1/4-N - Part Number: ASF-100-1/4-N

- Stauff ASF-025-1/4-N - Part Number: ASF-025-1/4-N

- Stauff ASF-050-1/4-N - Part Number: ASF-050-1/4-N

Recommended Replacement Period: Every 6 to 12 months.

Hy-Pro Filtration

Hy-Pro Filtration is a global provider of filtration products and solutions for various industries, including industrial, aerospace, and more. They offer a wide range of filter products, including hydraulic filters, air filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Hy-Pro HP12NL710MB - Part Number: HP12NL710MB

- Hy-Pro HP21L32MB - Part Number: HP21L32MB

- Hy-Pro HP16DNL156MB - Part Number: HP16DNL156MB

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Hy-Pro HPSF1304 - Part Number: HPSF1304

- Hy-Pro HPKT6L15MB - Part Number: HPKT6L15MB

- Hy-Pro HPSF1303 - Part Number: HPSF1303

Recommended Replacement Period: Every 6 to 12 months.

WIX Filters

WIX Filters is a global supplier of filtration products and solutions for various industries, including automotive, heavy duty, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- WIX Filters 51605 - Part Number: 51605

- WIX Filters 51515 - Part Number: 51515

- WIX Filters 51715 - Part Number: 51715

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- WIX Filters 42099 - Part Number: 42099

- WIX Filters 46637 - Part Number: 46637

- WIX Filters 42790 - Part Number: 42790

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- WIX Filters 24003 - Part Number: 24003

- WIX Filters 33960XE - Part Number: 33960XE

- WIX Filters 33270 - Part Number: 33270

Recommended Replacement Period: Every 3 to 6 months.

Gud Filters

Gud Filters is a global provider of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Gud Filters Z147 - Part Number: Z147

- Gud Filters Z239 - Part Number: Z239

- Gud Filters Z411 - Part Number: Z411

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Gud Filters AG1420 - Part Number: AG1420

- Gud Filters AG1170 - Part Number: AG1170

- Gud Filters AG1371 - Part Number: AG1371

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Gud Filters Z478 - Part Number: Z478

- Gud Filters Z175 - Part Number: Z175

- Gud Filters Z68 - Part Number: Z68

Recommended Replacement Period: Every 3 to 6 months.

SMC Corporation

SMC Corporation is a global provider of automation and filtration products and solutions for various industries, including industrial, automotive, and more. They offer a wide range of filter products, including air filters, water filters, and more.

Top 3 Filter Models and MPNs for Air Filters:

- SMC Corporation AFM20-02 - Part Number: AFM20-02

- SMC Corporation AF20-N02-Z - Part Number: AF20-N02-Z

- SMC Corporation AFM20-N02-CZ - Part Number: AFM20-N02-CZ

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Water Filters:

- SMC Corporation ALF111 - Part Number: ALF111

- SMC Corporation ALD310 - Part Number: ALD310

- SMC Corporation ALD410 - Part Number: ALD410

Recommended Replacement Period: Every 3 to 6 months.

Parker Hannifin

Parker Hannifin is a global provider of filtration products and solutions for various industries, including industrial, aerospace, and more. They offer a wide range of filter products, including hydraulic filters, air filters, water filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Parker Hannifin 937443Q - Part Number: 937443Q

- Parker Hannifin 932649Q - Part Number: 932649Q

- Parker Hannifin 933413Q - Part Number: 933413Q

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Parker Hannifin 12F24C2148AA - Part Number: 12F24C2148AA

- Parker Hannifin 12F25C2148AA - Part Number: 12F25C2148AA

- Parker Hannifin 14F11C18AC - Part Number: 14F11C18AC

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Water Filters:

- Parker Hannifin WS12 - Part Number: WS12

- Parker Hannifin W10 - Part Number: W10

- Parker Hannifin 14W10CN1K - Part Number: 14W10CN1K

Recommended Replacement Period: Every 3 to 6 months.

Zinga Industries

Zinga Industries is a global provider of filtration products and solutions for various industries, including industrial, agricultural, and more. They offer a wide range of filter products, including hydraulic filters, air filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Zinga Industries SRE25-10 - Part Number: SRE25-10

- Zinga Industries SE10-10 - Part Number: SE10-10

- Zinga Industries SRE10-10 - Part Number: SRE10-10

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Zinga Industries A-10 - Part Number: A-10

- Zinga Industries A-25 - Part Number: A-25

- Zinga Industries A-50 - Part Number: A-50

Recommended Replacement Period: Every 6 to 12 months.

Luber-finer

Luber-finer is a global provider of filtration products and solutions for various industries, including automotive, heavy duty, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Luber-finer LH2040 - Part Number: LH2040

- Luber-finer LH1056 - Part Number: LH1056

- Luber-finer LH5349 - Part Number: LH5349

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Luber-finer LAF2225 - Part Number: LAF2225

- Luber-finer LAF1849 - Part Number: LAF1849

- Luber-finer LAF1959 - Part Number: LAF1959

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Luber-finer LFF9275 - Part Number: LFF9275

- Luber-finer LFF5853 - Part Number: LFF5853

- Luber-finer LFF8062 - Part Number: LFF8062

Recommended Replacement Period: Every 3 to 6 months.

UFI Filters

UFI Filters is a global provider of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, oil filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- UFI Filters 23.152.00 - Part Number: 23.152.00

- UFI Filters 23.121.00 - Part Number: 23.121.00

- UFI Filters 23.123.00 - Part Number: 23.123.00

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- UFI Filters 27.791.00 - Part Number: 27.791.00

- UFI Filters 27.559.00 - Part Number: 27.559.00

- UFI Filters 27.930.00 - Part Number: 27.930.00

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Oil Filters:

- UFI Filters 25.102.00 - Part Number: 25.102.00

- UFI Filters 25.107.00 - Part Number: 25.107.00

- UFI Filters 25.077.00 - Part Number: 25.077.00

Recommended Replacement Period: Every 3 to 6 months.

Cummins Filtration

Cummins Filtration is a global provider of filtration products and solutions for various industries, including automotive, heavy duty, and more. They offer a wide range of filter products, including air filters, fuel filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- Cummins Filtration HF28806 - Part Number: HF28806

- Cummins Filtration HF35296 - Part Number: HF35296

- Cummins Filtration HF28938 - Part Number: HF28938

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- Cummins Filtration AF25550 - Part Number: AF25550

- Cummins Filtration AF25551 - Part Number: AF25551

- Cummins Filtration AF25552 - Part Number: AF25552

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Fuel Filters:

- Cummins Filtration FF63009 - Part Number: FF63009

- Cummins Filtration FF5636 - Part Number: FF5636

- Cummins Filtration FF5488 - Part Number: FF5488

Recommended Replacement Period: Every 3 to 6 months.

Sullair

Sullair is a global provider of filtration products and solutions for various industries, including industrial, aerospace, and more. They offer a wide range of filter products, including air filters, oil filters, and more.

Top 3 Filter Models and MPNs for Air Filters:

- Sullair 02250154-684 - Part Number: 02250154-684

- Sullair 2250151-544 - Part Number: 2250151-544

- Sullair 250034-122 - Part Number: 250034-122

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Oil Filters:

- Sullair 02250155-743 - Part Number: 02250155-743

- Sullair 250034-084 - Part Number: 250034-084

- Sullair 250034-087 - Part Number: 250034-087

Recommended Replacement Period: Every 3 to 6 months.

MANN+HUMMEL

MANN+HUMMEL is a global provider of filtration products and solutions for various industries, including automotive, industrial, and more. They offer a wide range of filter products, including air filters, oil filters, hydraulic filters, and more.

Top 3 Filter Models and MPNs for Hydraulic Filters:

- MANN+HUMMEL H722X - Part Number: H722X

- MANN+HUMMEL H718X - Part Number: H718X

- MANN+HUMMEL H719X - Part Number: H719X

Recommended Replacement Period: Every 3 to 6 months.

Top 3 Filter Models and MPNs for Air Filters:

- MANN+HUMMEL C 39 002 - Part Number: C 39 002

- MANN+HUMMEL C 25 005 - Part Number: C 25 005

- MANN+HUMMEL C 27 110 - Part Number: C 27 110

Recommended Replacement Period: Every 6 to 12 months.

Top 3 Filter Models and MPNs for Oil Filters:

- MANN+HUMMEL W 962/7 - Part Number: W 962/7

- MANN+HUMMEL HU 719/7 x - Part Number: HU 719/7 x

- MANN+HUMMEL W 940/19 - Part Number: W 940/19

Recommended Replacement Period: Every 3 to 6 months.

These are the top 25 industrial filter suppliers in the USA, along with the types of filters they provide, the industries they serve, the top 3 filter models and MPNs for each type of filter, the recommended replacement period, and the approximate price range.

Please note that the prices of filters may vary depending on the supplier and location. It is always recommended to compare prices and quality before making a purchase.

Part V: The top 50 Indications Filters need to be replaced

Here are the top 50 indications that your filters need to be replaced:

Air Filters (1-5):

- Reduced airflow from vents

- Visible dirt or debris on the filter

- Unusual noises from the HVAC system

- Unpleasant odors from the HVAC system

- Poor indoor air quality, including increased dust or allergens

Oil Filters (6-10):

- Reduced engine performance

- Unusual engine noises, such as knocking or ticking

- Engine warning light on the dashboard

- Oil pressure warning light on the dashboard

- Dirty or dark oil on the dipstick

Hydraulic Filters (11-15):

- Reduced hydraulic system performance

- Unusual noises from the hydraulic system

- Slow or jerky movement of equipment

- Leaking hydraulic fluid

- Contaminated hydraulic fluid

Fuel Filters (16-20):

- Reduced engine performance

- Difficulty starting the engine

- Unusual engine noises, such as sputtering or misfiring

- Engine warning light on the dashboard

- Dirty or contaminated fuel in the tank

Water Filters (21-25):

- Reduced water pressure

- Unusual noises from the plumbing system

- Unpleasant tastes or odors in the water

- Visible dirt or debris in the water

- Water discoloration or staining of fixtures

Pool Filters (26-30):

- Cloudy or murky pool water

- Algae growth in the pool

- Reduced water flow from pool jets

- Dirty or clogged filter cartridges

- High levels of pool chemicals despite regular maintenance

Vacuum Filters (31-35):

- Reduced suction power from the vacuum

- Unusual noises from the vacuum motor

- Dust or debris escaping from the vacuum

- Filter clogging or tearing

- Foul odors from the vacuum

Dust Collector Filters (36-40):

- Reduced suction power from the dust collector

- Visible dust buildup on the filter

- Poor air quality in the workspace

- Dust or debris escaping from the dust collector

- Unusual noises from the dust collector motor

Cabin Air Filters (41-45):

- Reduced airflow from the HVAC system

- Unpleasant odors from the HVAC system

- Poor indoor air quality, including increased dust or allergens

- Reduced heating or cooling performance

- Dust or debris on the filter

Industrial Water Treatment Filters (46-50):

- Reduced water flow rate

- Reduced water pressure

- Increased water turbidity or cloudiness

- Visible dirt or debris on the filter

- High levels of water contaminants despite regular treatment

It is important to keep an eye out for these indications and replace filters as necessary to ensure optimal performance and efficiency of industrial products. Regular maintenance and replacement of filters can also extend the lifespan of equipment and prevent costly repairs.

Part VI: The top 25 industries and applications that require filters

Top 25 Industries:

- Automotive

- Aerospace

- Construction

- Chemicals

- Pharmaceuticals

- Food and Beverage

- Mining

- Oil and Gas

- Power Generation

- Water Treatment

- Agriculture

- Textiles

- Pulp and Paper

- Plastics

- Semiconductor

- Healthcare

- Cosmetics

- Environmental Services

- Packaging

- Printing and Publishing

- Transportation

- Marine

- Military and Defense

- Telecommunications

- HVAC and Refrigeration

Top 25 Applications:

- Air Filtration

- Oil Filtration

- Hydraulic Filtration

- Fuel Filtration

- Water Filtration

- Pool Filtration

- Vacuum Filtration

- Dust Collection

- Cabin Air Filtration

- Industrial Water Treatment

- Process Water Treatment

- Cooling Tower Filtration

- Compressed Air Filtration

- Breathing Air Filtration

- Paint Booth Filtration

- Gas Filtration

- Liquid Filtration

- High-Purity Filtration

- Food and Beverage Filtration

- Chemical Filtration

- Pharmaceutical Filtration

- Semiconductor Wafer Processing

- Cleanroom Filtration

- Military and Defense Filtration

- HVAC and Refrigeration Filtration

Filters are essential components in various industries and applications to maintain fluid and air quality, improve efficiency, and ensure safety. These top 25 industries and top 25 applications represent the most common uses of filters and filter replacements. It is important to choose the appropriate type of filter and maintain it regularly to ensure optimal performance and longevity of industrial products.

Part VII: The top 50 Online Sellers of Industrial Filters

- Amazon - Offers a wide range of industrial filters for various applications and industries. Free shipping is available for some products with Amazon Prime membership. Price range: 1-10.

- Grainger - Specializes in industrial supplies and offers a broad range of filters for various applications. Free shipping is available for orders over $75. Price range: 3-8.

- Zoro - Offers a large selection of industrial filters for various applications and industries. Free shipping is available for orders over $50. Price range: 2-9.

- FilterBuy - Specializes in air filters for residential and commercial use. Offers free shipping on all orders. Price range: 3-6.

- FiltersFast - Offers a broad range of filters for various applications, including air, water, and more. Free shipping is available for orders over $75. Price range: 3-8.

- Industrial Filter Store - Offers a wide range of industrial filters, including air, oil, hydraulic, fuel, and more. Free shipping is available for orders over $50. Price range: 2-9.

- Filtra-Systems - Specializes in industrial water filtration systems and offers a variety of filter products for water treatment applications. Price range: 5-9.

- GoVets - Offers a large selection of industrial filters, including air, oil, hydraulic, fuel, and more. Free shipping is available on all orders. Price range: 3-8.

- Filter Solutions - Offers a wide range of industrial filters, including air, oil, hydraulic, fuel, and more. Free shipping is available for orders over $99. Price range: 2-9.

- DiscountFilters - Offers a large selection of air and water filters for residential and commercial use. Free shipping is available for orders over $50. Price range: 2-7.

- Filter Products Company - Offers a variety of industrial filters for air, liquid, and gas applications. Free shipping is available for orders over $100. Price range: 3-8.

- US Water Systems - Specializes in water filtration systems and offers a variety of filter products for residential and commercial use. Free shipping is available for most orders. Price range: 5-9.

- Filters-NOW - Offers a broad range of air and water filters for residential and commercial use. Free shipping is available for most orders. Price range: 2-7.

- FilterPro - Offers a wide range of industrial filters, including air, oil, hydraulic, fuel, and more. Free shipping is available for orders over $75. Price range: 2-9.

- Kleen-Rite - Specializes in car wash supplies and offers a variety of filter products for water treatment applications. Free shipping is available for orders over $50. Price range: 3-8.

- Industrial Filters Online - Offers a broad range of industrial filters for various applications and industries. Free shipping is available for most orders. Price range: 2-9.

- Air Filters Delivered - Offers a large selection of air filters for residential and commercial use. Free shipping is available for most orders. Price range: 2-6.

- KleenWater - Specializes in water filtration systems and offers a variety of filter products for residential and commercial use. Free shipping is available for most orders. Price range: 3-8.

- HVAC Filters - Offers a broad range of air filters for residential and commercial HVAC systems. Free shipping is available for most orders. Price range: 2-6.

- Industrial Filter Manufacturers - Offers a variety of industrial filters, including air, liquid, and gas filtration products. Free shipping is available for most orders. Price range: 3-9.

- HVAC Parts Outlet - Offers a wide range of air filters for residential and commercial HVAC systems. Free shipping is available for most orders. Price range: 2-6.

- Lennox Filters - Specializes in air filters for Lennox HVAC systems. Free shipping is available for most orders. Price range: 4-7.

- Discount Filter Store - Offers a broad range of air and water filters for residential and commercial use. Free shipping is available for most orders. Price range: 2-7.

- HVAC Air Filters - Offers a variety of air filters for residential and commercial HVAC systems. Free shipping is available for most orders. Price range: 2-6.

It is important to note that the price ranges provided may vary depending on the product, brand, and supplier. Customers should always compare prices and quality before making a purchase to ensure they are getting the best value for their money. Additionally, customers should also consider factors such as shipping time, customer service, and return policy when choosing an online seller for their industrial filter needs.

Part VIII: Can Filters be returned after they are purchased?

Additionally, some suppliers may require customers to obtain a Return Merchandise Authorization (RMA) number before returning a filter. Customers should contact the supplier's customer service to obtain an RMA number and to understand the return procedure.

If a filter has been used, it may not be eligible for return, as it may have been contaminated or damaged during use. In such cases, it is important to properly dispose of the filter and replace it with a new one.

Part IX: The top 10 reasons why filter returns are rejected by retailers

Here are the top 10 reasons why filter returns may be rejected by retailers:

- The filter has been used or installed: Once a filter has been used or installed, it may no longer be eligible for return, as it may have been contaminated or damaged during use. Retailers may reject returns for filters that show signs of use or installation.

- The filter is damaged: Filters may be damaged during shipping, handling, or installation, which may make them unsuitable for return. Retailers may reject returns for filters that show signs of damage or mishandling.

- The packaging is damaged or missing: Filters must be returned in their original packaging to be eligible for return. If the packaging is missing or damaged, retailers may reject the return.

- The return is outside of the return window: Retailers may have specific return windows within which returns must be initiated. If the return is initiated outside of this window, it may be rejected.

- The customer did not obtain an RMA: Retailers may require customers to obtain a Return Merchandise Authorization (RMA) number before returning a filter. If the customer did not obtain an RMA, the return may be rejected.

- The filter is not in resalable condition: Filters must be returned in the same condition in which they were received to be eligible for return. If the filter is not in resalable condition, the return may be rejected.

- The filter was customized or made to order: Filters that have been customized or made to order may not be eligible for return. Retailers may reject returns for such filters.

- The customer ordered the wrong filter: If the customer ordered the wrong filter, the return may be rejected. In some cases, retailers may allow exchanges for the correct filter.

- The customer damaged the filter during installation: Filters may be damaged during installation if not done properly. If the customer damaged the filter during installation, the return may be rejected.

- The filter was a clearance item: Filters that are marked as clearance items may not be eligible for return. Retailers may reject returns for clearance items.

It is important to carefully read and understand the retailer's return policy before making a purchase to avoid any issues with returns. If a filter needs to be returned, customers should follow the return policy and ensure that the filter is returned in the same condition in which it was received to avoid rejection of the return.

Part X: The top 25 tips for customers that are about to purchase a filter

Here are the top 25 tips for customers to ensure that they are satisfied with their industrial filter purchase:

- Identify your filtration needs: Determine the type of filter you need based on the application, industry, and the fluid or gas to be filtered.

- Choose the right filter media: Choose the appropriate filter media based on the specific contaminants that need to be removed.

- Check the filter size: Make sure that the filter size matches the dimensions of the system or equipment.

- Check the filter compatibility: Ensure that the filter is compatible with the fluid or gas being filtered and with the system or equipment.

- Check the filter's micron rating: Choose a filter with a micron rating that is appropriate for the level of filtration required.

- Check the filter's efficiency rating: Choose a filter with an efficiency rating that is appropriate for the level of filtration required.

- Check the filter's pressure drop: Choose a filter with a pressure drop that is appropriate for the system or equipment.

- Consider the filter's lifespan: Choose a filter with a lifespan that matches the expected use.

- Check the filter's flow rate: Choose a filter with a flow rate that matches the system or equipment.

- Check the filter's temperature rating: Choose a filter with a temperature rating that is appropriate for the fluid or gas being filtered.

- Choose a reputable supplier: Choose a supplier with a good reputation for quality and customer service.

- Check the supplier's return policy: Make sure that the supplier's return policy is reasonable and meets your needs.

- Check the supplier's shipping policy: Make sure that the supplier's shipping policy is reasonable and meets your needs.

- Check the supplier's pricing: Compare the pricing of different suppliers to ensure that you are getting a fair price.

- Look for promotions or discounts: Look for promotions or discounts that may be available to save money on your purchase.

- Read customer reviews: Read customer reviews of the product and supplier to gain insight into the product's performance and the supplier's customer service.

- Check the product's warranty: Make sure that the product has a warranty that meets your needs.

- Consult with experts: Consult with experts in the industry to ensure that you are choosing the right filter for your needs.

- Consider eco-friendly options: Consider eco-friendly filter options to reduce your environmental impact.

- Ensure proper installation: Ensure that the filter is properly installed according to the manufacturer's instructions.

- Monitor filter performance: Monitor the filter's performance to ensure that it is operating correctly.

- Replace filters regularly: Replace filters regularly to ensure optimal performance and avoid damage to equipment.

- Properly dispose of used filters: Properly dispose of used filters according to local regulations.

- Keep records of filter replacement: Keep records of filter replacement to track filter performance and ensure proper maintenance.

- Seek assistance if needed: If you are unsure about the best filter choice or installation process, seek assistance from a qualified professional.

- Consider buying filters in bulk: Buying filters in bulk can often be more cost-effective than purchasing individual filters.

- Look for filters with a long service life: Choosing filters with a longer service life can reduce the frequency of filter replacements and save money in the long term.

- Consider the filter's environmental impact: Consider the filter's environmental impact and choose eco-friendly options where possible.

- Choose filters with high dirt-holding capacity: Filters with a high dirt-holding capacity can reduce the frequency of filter replacements and save money in the long term.

- Check for certifications: Look for filters that have been certified by recognized organizations to ensure that they meet quality standards.

- Consider the filter's ease of maintenance: Choose filters that are easy to maintain and replace to reduce maintenance time and costs.

- Check the filter's compatibility with existing equipment: Ensure that the filter is compatible with existing equipment to avoid compatibility issues.

- Look for filters with low pressure drops: Filters with low pressure drops can improve system efficiency and reduce energy costs.

- Consider the filter's resistance to clogging: Choose filters that are resistant to clogging to reduce filter replacement frequency.

- Check the filter's ease of installation: Choose filters that are easy to install to reduce installation time and costs.

- Consider the filter's ability to remove contaminants: Choose filters that are effective in removing specific contaminants to ensure optimal filtration.

- Look for filters with a wide range of temperature tolerances: Filters with a wide range of temperature tolerances can be used in a variety of applications and environments.

- Check the filter's ability to handle high flow rates: Choose filters that can handle high flow rates to avoid system overload.

- Consider the filter's ability to handle high pressures: Choose filters that can handle high pressures to avoid damage to the filter and equipment.

- Check the filter's compatibility with different fluids and gases: Ensure that the filter is compatible with different fluids and gases to avoid compatibility issues.

- Look for filters with easy-to-read pressure gauges: Filters with easy-to-read pressure gauges can help monitor filter performance and ensure optimal filtration.

- Consider the filter's maintenance requirements: Choose filters that have minimal maintenance requirements to reduce maintenance time and costs.

- Check the filter's resistance to chemicals: Choose filters that are resistant to chemicals to avoid filter damage and contamination.

- Look for filters with a high flow rate per unit of pressure drop: Filters with a high flow rate per unit of pressure drop can improve system efficiency and reduce energy costs.

- Consider the filter's ability to handle high levels of moisture: Choose filters that can handle high levels of moisture to avoid filter damage and contamination.

- Check the filter's compatibility with different types of filtration systems: Ensure that the filter is compatible with different types of filtration systems to avoid compatibility issues.

- Look for filters with a high-efficiency rating: Filters with a high-efficiency rating can provide optimal filtration and remove even the smallest particles.

- Consider the filter's ability to reduce odors: Choose filters that can reduce odors to improve air quality and reduce unpleasant smells.

- Check the filter's ability to handle high levels of humidity: Choose filters that can handle high levels of humidity to avoid filter damage and contamination.

- Consider the filter's overall value: Consider the filter's overall value, including its price, performance, lifespan, and maintenance requirements, to ensure that it is the best choice for your needs.

Part XI: What are the top 10 factors that make for high-quality filters?

- Filter media: High quality filters use filter media that effectively remove contaminants and provide optimal filtration.

- Micron rating: Filters with a low micron rating are able to remove smaller particles and provide higher quality filtration.

- Flow rate: High quality filters are able to maintain a consistent flow rate, even as they become clogged with contaminants.

- Pressure drop: High quality filters have a low pressure drop, meaning that they do not impede the flow of fluid or gas through the system.

- Efficiency rating: Filters with a high efficiency rating are able to remove a high percentage of contaminants from the fluid or gas being filtered.

- Lifespan: High quality filters have a long lifespan and are able to maintain optimal performance throughout their lifetime.

- Compatibility: High quality filters are designed to be compatible with a wide range of fluids and gases, and with different types of filtration systems.

- Resistance to damage: High quality filters are resistant to damage from chemicals, temperature changes, and other environmental factors.

- Ease of installation: High quality filters are easy to install and remove, and are designed to fit securely in the filtration system.

- Maintenance requirements: High quality filters have minimal maintenance requirements, and are easy to clean or replace when needed.

Part XII: The top materials used for filters?

There are a variety of materials used for filters, each with their own unique properties and applications. Here are some of the top materials used for filters:

- Paper: Paper filters are commonly used for air and liquid filtration. They are made from cellulose fibers and are relatively inexpensive.

- Polyester: Polyester filters are used for air and liquid filtration, and are known for their durability and resistance to damage.

- Nylon: Nylon filters are used for liquid filtration, and are known for their high strength and resistance to chemicals.

- Polypropylene: Polypropylene filters are used for liquid filtration, and are known for their resistance to corrosion and chemicals.

- Carbon: Carbon filters are used for air and water filtration, and are known for their ability to remove odors, tastes, and impurities.

- Ceramic: Ceramic filters are used for water filtration, and are known for their ability to remove bacteria and other microorganisms.

- Glass: Glass filters are used for air and liquid filtration, and are known for their durability and resistance to high temperatures.

- Metal: Metal filters are used for air filtration, and are known for their durability and resistance to corrosion.

- Membrane: Membrane filters are used for air and liquid filtration, and are known for their ability to remove small particles and bacteria.

- Activated Alumina: Activated alumina filters are used for air and water filtration, and are known for their ability to remove fluoride and other impurities.

It is important to choose the right filter material based on the specific application and contaminants that need to be removed.

Part XIII: The highest quality materials used for filters

The highest quality materials used for filters depend on the specific application and the level of filtration required. Here are some examples of high-quality filter materials:

- PTFE (Polytetrafluoroethylene): PTFE is a synthetic fluoropolymer that is used for air, gas, and liquid filtration. It is known for its high chemical resistance and ability to filter out very small particles.

- Stainless Steel: Stainless steel is a durable and corrosion-resistant material that is commonly used for air and liquid filtration. It is ideal for applications where high temperatures and pressures are involved.

- Ceramic: Ceramic filters are made from porous ceramic materials and are used for water filtration. They are known for their ability to remove bacteria and other microorganisms, and are often used in developing countries where access to clean water is limited.

- Activated Carbon: Activated carbon filters are used for air and water filtration and are known for their ability to remove odors, tastes, and impurities. They are made from activated carbon particles that are porous and have a large surface area, allowing them to effectively adsorb contaminants.

- Cellulose: Cellulose filters are made from wood pulp and are commonly used for air and liquid filtration. They are known for their high filtration efficiency and low cost.

- Nylon: Nylon filters are used for liquid filtration and are known for their high strength and resistance to chemicals. They are often used in applications where high pressures and temperatures are involved.

- Polypropylene: Polypropylene filters are commonly used for liquid filtration and are known for their resistance to corrosion and chemicals. They are ideal for applications where harsh chemicals are present.

- Glass Fiber: Glass fiber filters are used for air filtration and are known for their high filtration efficiency and ability to remove very small particles. They are commonly used in laboratory applications.

- Membrane: Membrane filters are used for air and liquid filtration and are known for their ability to remove small particles and bacteria. They are commonly used in medical and laboratory applications.

- Silica Gel: Silica gel filters are used for air and gas filtration and are known for their ability to remove moisture and humidity from the air or gas being filtered.

It is important to choose the highest quality filter material for the specific application to ensure optimal filtration and long-term performance.

Part XIV: Can filters last forever?

No, it is not possible for filters to last forever. Over time, filters will become clogged with contaminants and lose their ability to effectively filter out particles, odors, and impurities. While some filters may last longer than others, they will eventually need to be replaced or cleaned to maintain optimal performance.

The lifespan of a filter depends on several factors, including the type of filter, the level of filtration required, and the conditions of the application. For example, a filter used in a dusty environment may need to be replaced more frequently than a filter used in a clean room environment.

It is important to monitor the performance of filters regularly and replace them when necessary to avoid damage to equipment and ensure optimal filtration. Many manufacturers provide guidelines for recommended filter replacement intervals based on the specific application and conditions. Following these guidelines can help extend the life of the equipment and ensure that the filter is functioning correctly.

Part XV: Recommended Professionals for different filter applications

- Engineers: Engineers with expertise in mechanical, chemical, or environmental engineering can recommend filters for a variety of applications based on their technical knowledge and experience.

- Environmental Health and Safety (EHS) professionals: EHS professionals can recommend filters to protect workers from exposure to hazardous materials in the workplace. They may also recommend filters for air or water purification in buildings or other environments.

- Industrial Hygienists: Industrial hygienists are trained to identify and control workplace hazards. They may recommend filters to protect workers from exposure to hazardous chemicals, dust, or other materials.

- HVAC Technicians: HVAC technicians can recommend filters for heating, ventilation, and air conditioning systems to improve indoor air quality and reduce energy consumption.

- Water Treatment Specialists: Water treatment specialists can recommend filters for water treatment systems in a variety of industries, including food and beverage, pharmaceuticals, and electronics.

- Laboratory Technicians: Laboratory technicians can recommend filters for use in laboratory settings for air and water purification and to maintain sterile conditions.

- Filtration Experts: Filtration experts specialize in the design and application of filtration systems for a variety of applications and industries.

It is important to consult with a professional to ensure that the appropriate filter is chosen for the specific application and contaminants that need to be removed.

Part XVI: Top 10 reasons why customers choose GoVets when shopping for Filters

Here are the top 10 reasons why customers choose GoVets when shopping for industrial filters for all types of applications and industries:

- Wide Range of Products: GoVets offers a vast selection of industrial filters from top brands for all types of applications and industries, making it a one-stop-shop for customers' filtration needs.

- Competitive Pricing: GoVets offers competitive pricing for industrial filters, ensuring that customers get the best value for their money.

- Quality Products: GoVets only offers high-quality industrial filters from trusted brands, ensuring that customers receive reliable and effective filtration solutions.

- Quick and Easy Ordering: GoVets offers a user-friendly online platform for ordering industrial filters, making it easy and convenient for customers to find the right filter and place an order.

- Fast Shipping: GoVets offers fast and reliable shipping options, ensuring that customers receive their filters quickly and efficiently.

- Excellent Customer Service: GoVets has a dedicated customer service team that is available to assist customers with any questions or concerns they may have about their orders or products.

- Government Approved: GoVets is an authorized vendor for the US government, making it a trusted source for industrial filters for government agencies and contractors.

- Secure Payment Options: GoVets offers secure payment options, ensuring that customers' payment information is protected.

- Sustainable Products: GoVets offers a selection of eco-friendly and sustainable industrial filters, helping customers reduce their environmental impact.

- Support for Veterans: GoVets is a veteran-owned and operated business, and a portion of every purchase goes towards supporting veteran-owned businesses and organizations.

These top 10 reasons make GoVets a reliable and trusted source for industrial filters for all types of applications and industries. Customers can trust GoVets to provide high-quality products, competitive pricing, excellent customer service, and support for sustainable and veteran-owned businesses.

Conclusion:

Choosing the right industrial filter is critical to maintaining optimal performance and efficiency in your systems and processes. With the information provided in this guide, you can make informed decisions about the types of filters to use, when to replace them, and where to purchase them. Whether you need filters for air and water purification, HVAC systems, or manufacturing processes, GoVets is the trusted source for high-quality filters and exceptional customer service. With their extensive selection of filters and commitment to customer satisfaction, GoVets is the clear choice for all your filter needs.