Mastering the Drill Press: A Comprehensive Guide to Types, Applications, and Product Recommendations

Introduction:

When it comes to precision drilling tasks, having the right equipment can make all the difference in achieving accurate results efficiently. From metal fabrication to woodworking and construction, drill presses play a vital role in various industries, offering stability, precision, and power for a wide range of applications. However, with so many types of drill presses available on the market, each with its own unique features and capabilities, choosing the right one can be a daunting task.

In this comprehensive guide, we'll delve into the world of drill presses, exploring the different types available, their typical applications, top reasons to use each type, frequently asked questions, essential product add-ons, and recommended products. Whether you're a seasoned professional or a DIY enthusiast, this guide will equip you with the knowledge and insights you need to select the perfect drill press for your specific needs. So let's dive in and master the art of drilling with confidence and precision!

- Floor & Bench Drill Presses

- Drill Presses & Tapping Machines

- Portable Drill Presses

- Floor Standing and Bench Mounted Drill Presses

- Corded Magnetic Drill Presses

- Cordless Magnetic Drill Presses

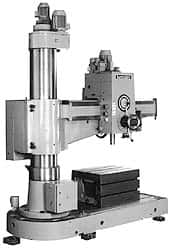

1. Floor & Bench Drill Presses

Floor and bench drill presses are essential tools in any workshop or industrial setting. They come in various sizes and configurations, suitable for both DIY enthusiasts and professional craftsmen. These drills provide precision and power, making them ideal for drilling consistent, accurate holes in various materials.

Typical Applications:

- Woodworking: Perfect for creating precise holes in wood for joinery, doweling, and other woodworking tasks.

- Metalworking: Essential for drilling holes in metal for fabrication, machining, and metalworking projects.

- Construction: Used for drilling holes in construction materials like concrete, brick, and stone for installation and renovation projects.

- DIY Projects: Handy for a wide range of DIY tasks, from furniture making to home repairs and renovations.

- Electrical Work: Useful for drilling holes in panels, junction boxes, and other electrical components during installation or repair work.

Top 5 Reasons to Use Floor & Bench Drill Presses:

- Precision: Provides accurate drilling depth and angle, ensuring consistent results.

- Power: Offers high torque and speed for efficient drilling through tough materials.

- Versatility: Can accommodate various drill bit sizes and types for diverse drilling needs.

- Stability: Stable base and clamping mechanisms ensure steady drilling without wobbling.

- Efficiency: Saves time and effort compared to handheld drills, especially for repetitive drilling tasks.

Top 10 FAQs and Answers:

- Q: Can I use a floor drill press on a bench? A: Yes, many floor drill presses can be converted for bench use with the appropriate mounting accessories.

- Q: What maintenance does a drill press require? A: Regular cleaning, lubrication of moving parts, and checking for alignment are essential maintenance tasks.

- Q: Can I use a floor drill press for tapping threads? A: Yes, with the addition of a tapping attachment or tapping head, a drill press can be used for tapping operations.

- Q: How do I choose the right drill press size? A: Consider the size of your workpieces and the maximum drilling capacity required to select the appropriate drill press size.

- Q: Can I use a drill press for milling operations? A: While not ideal, certain drill presses can be adapted for light milling tasks with the right accessories.

- Q: What safety precautions should I take when using a drill press? A: Always wear safety glasses, secure workpieces properly, and avoid wearing loose clothing or jewelry.

- Q: Can I use drill bits other than twist drills? A: Yes, many drill presses can accommodate various types of drill bits, including spade bits, hole saws, and Forstner bits.

- Q: How do I adjust the speed of a drill press? A: Most drill presses feature adjustable speed settings either through a belt and pulley system or electronic controls.

- Q: Can I drill angled holes with a drill press? A: Yes, many drill presses allow for tilting the worktable or the drill head to drill holes at angles.

- Q: Are floor drill presses portable? A: While floor drill presses are typically heavier and less portable than benchtop models, some feature built-in wheels for easier mobility.

Top 5 Product Add-Ons:

- Drill Press Vises: Essential for securing workpieces firmly in place during drilling operations.

- Drill Press Stand: Converts handheld drills into stationary drill presses for added stability and precision.

- Drill Bits Set: A comprehensive set of drill bits in various sizes and types for versatile drilling applications.

- Laser Guide Attachment: Provides visual guidance for precise drilling accuracy and alignment.

- Dust Collection System: Helps keep the work area clean by capturing dust and debris generated during drilling.

Product Recommendations:

-

Snap-OnSpecial Price $3939.29 Regular Price $5166.43This product is sold in increments of 1

-

Value CollectionSpecial Price $78636.49 Regular Price $110091.09This product is sold in increments of 1

-

Value CollectionSpecial Price $87274.49 Regular Price $122184.29This product is sold in increments of 1

-

BaileighSpecial Price $2187.99 Regular Price $3063.19This product is sold in increments of 1

-

BaileighSpecial Price $13152.79 Regular Price $18413.91This product is sold in increments of 1

-

ImportSpecial Price $38228.99 Regular Price $48363.12This product is sold in increments of 1

-

ImportSpecial Price $52002.29 Regular Price $65787.17This product is sold in increments of 1

-

ImportSpecial Price $70411.29 Regular Price $89076.68This product is sold in increments of 1

3. Portable Drill Presses

Portable drill presses offer the convenience of mobility without sacrificing drilling precision. These compact and lightweight units are ideal for on-the-go drilling tasks in remote locations or job sites where a stationary drill press is impractical.

Typical Applications:

- Field Work: Perfect for drilling holes in construction materials, metal pipes, and structural components on job sites.

- Maintenance & Repair: Handy for onsite repairs, installations, and maintenance tasks where access to a workshop is limited.

- Emergency Repairs: Essential for emergency repairs and maintenance tasks in remote locations or during outdoor events.

- DIY Projects: Suitable for hobbyists and DIY enthusiasts who require a portable drilling solution for home projects.

- Automotive Maintenance: Used for drilling holes in automotive parts and assemblies during roadside repairs or off-site maintenance.

Top 5 Reasons to Use Portable Drill Presses:

- Portability: Lightweight and compact design allows for easy transportation to remote locations and job sites.

- Versatility: Can be used with a wide range of drill bits and accessories for diverse drilling applications.

- Convenience: Provides the flexibility to perform drilling tasks anywhere, without the need for a dedicated workshop.

- Efficiency: Saves time and effort compared to handheld drills by offering stable and precise drilling performance.

- Space-Saving: Ideal for small workshops or crowded job sites where space is limited, as they take up minimal floor space.

Top 10 FAQs and Answers:

- Q: Are portable drill presses as accurate as stationary drill presses? A: While portable drill presses may not offer the same level of precision as stationary models, they provide sufficient accuracy for most drilling tasks.

- Q: Can I use a portable drill press for tapping threads? A: Some portable drill presses may be compatible with tapping attachments or adapters for tapping operations.

- Q: How do I secure a portable drill press for drilling? A: Use clamps or mounting brackets to secure the portable drill press to a stable surface, such as a workbench or table.

- Q: Can I drill large diameter holes with a portable drill press? A: Portable drill presses are typically limited in drilling capacity compared to stationary models, so large diameter holes may require specialized equipment.

- Q: Are battery-powered portable drill presses available? A: Yes, some portable drill presses are battery-powered for added convenience and mobility, especially in remote locations without access to electricity.

- Q: How do I adjust the drilling speed on a portable drill press? A: Some portable drill presses feature variable speed controls, while others may have fixed speed settings.

- Q: Can I use portable drill presses for angled drilling? A: While not common, certain portable drill presses may offer tilting or swiveling capabilities for angled drilling.

- Q: What safety precautions should I take when using a portable drill press? A: Always secure the workpiece properly, wear appropriate safety gear, and avoid operating the drill press near flammable materials or in hazardous environments.

- Q: Are there any accessories available for portable drill presses? A: Yes, accessories such as drill press vises, angle guides, and depth stops can enhance the functionality and versatility of portable drill presses.

- Q: Can I use portable drill presses for heavy-duty drilling tasks? A: While portable drill presses are suitable for light to medium-duty drilling, they may not be suitable for heavy-duty industrial applications requiring high torque and drilling capacity.

Top 5 Product Add-Ons:

- Portable Workbench: Provides a stable surface for mounting the portable drill press and clamping workpieces securely.

- Drill Guide Jigs: Helps maintain drilling accuracy and alignment for precise hole drilling in various materials.

- Tool Storage Case: Conveniently stores the portable drill press and accessories for easy transportation and organization.

- Battery Packs and Chargers: Essential for battery-powered portable drill presses to ensure uninterrupted operation.

- Dust Collection Attachment: Helps keep the work area clean by capturing dust and debris generated during drilling operations.

Product Recommendations:

-

HougenSpecial Price $1524.29 Regular Price $2134.01This product is sold in increments of 1

-

Nitto KohkiSpecial Price $1106.79 Regular Price $1732.83This product is sold in increments of 1

-

DeWALTSpecial Price $1520.79 Regular Price $2386.74This product is sold in increments of 1

-

FeinSpecial Price $1317.99 Regular Price $2068.46This product is sold in increments of 1

-

MetaboSpecial Price $2161.99 Regular Price $3400.51This product is sold in increments of 1

-

Nitto KohkiSpecial Price $4381.99 Regular Price $6922.21This product is sold in increments of 1

-

Nitto KohkiSpecial Price $5184.79 Regular Price $8208.18This product is sold in increments of 1

-

Nitto KohkiSpecial Price $1158.99 Regular Price $1814.92This product is sold in increments of 1

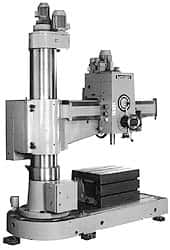

4. Floor Standing and Bench Mounted Drill Presses

Floor standing and bench-mounted drill presses offer stability and precision for heavy-duty drilling tasks. These robust machines are ideal for workshops, fabrication facilities, and industrial settings where accuracy and reliability are essential.

Typical Applications:

- Metal Fabrication: Used for drilling precise holes in metal sheets, plates, and structural components for fabrication and assembly.

- Woodworking: Essential for creating accurate holes in wood for furniture making, cabinetry, and carpentry projects.

- Machining: Critical for machining operations requiring precise hole drilling in various materials, including plastics and composites.

- Maintenance & Repair: Handy for maintenance technicians and repair professionals working on equipment and machinery.

- Production Work: Ideal for high-volume drilling tasks in manufacturing environments, such as drilling holes in parts and components.

Top 5 Reasons to Use Floor Standing and Bench Mounted Drill Presses:

- Stability: Solid construction and heavy-duty bases provide stability and minimize vibration for accurate drilling.

- Power: Offers high torque and horsepower for drilling through tough materials with ease.

- Versatility: Can accommodate a wide range of drill bit sizes and types for diverse drilling applications.

- Precision: Features precise depth control, table adjustments, and spindle speed settings for consistent drilling results.

- Durability: Built to withstand the rigors of industrial use, ensuring long-term performance and reliability.

Top 10 FAQs and Answers:

- Q: What's the difference between floor standing and bench-mounted drill presses? A: Floor standing drill presses are larger and typically offer greater drilling capacity and power compared to bench-mounted models, which are more compact and suitable for smaller workshops.

- Q: Can I convert a bench-mounted drill press into a floor-standing model? A: Some bench-mounted drill presses may be compatible with floor-standing conversion kits, but it's essential to check with the manufacturer for compatibility.

- Q: What accessories are available for floor standing and bench-mounted drill presses? A: Accessories include drill press vises, angle guides, rotary tables, and mortising attachments to enhance the functionality and versatility of the drill press.

- Q: How do I adjust the spindle speed on a drill press? A: Most drill presses feature adjustable speed settings either through a belt and pulley system or electronic controls.

- Q: Can I use coolant with a drill press for metalworking? A: Yes, coolant can be used to lubricate and cool the drill bit during metal drilling operations, reducing friction and extending tool life.

- Q: How do I maintain a floor standing or bench-mounted drill press? A: Regular cleaning, lubrication of moving parts, checking for alignment, and inspecting belts and pulleys are essential maintenance tasks.

- Q: Can I use a floor standing drill press for tapping threads? A: Yes, with the addition of a tapping attachment or tapping head, a floor standing drill press can be used for tapping operations.

- Q: Are there any safety precautions I should take when using a drill press? A: Always wear safety glasses, secure workpieces properly, and avoid wearing loose clothing or jewelry. Additionally, ensure the drill press is securely anchored to the floor or workbench.

- Q: Can I use drill bits other than twist drills with a drill press? A: Yes, drill presses can accommodate various types of drill bits, including spade bits, hole saws, and Forstner bits.

- Q: Can I use a drill press for milling operations? A: While not ideal, certain drill presses can be adapted for light milling tasks with the right accessories and setup.

Top 5 Product Add-Ons:

- Drill Press Vises: Essential for securing workpieces firmly in place during drilling operations.

- Rotary Tables: Allows for precise positioning and rotation of workpieces for drilling holes at specific angles or in circular patterns.

- Mortising Attachments: Enables the drill press to perform mortising operations for joinery and woodworking projects.

- Angle Guides: Provides accurate angle adjustments for drilling holes at precise angles.

- Digital Depth Gauge: Allows for precise depth measurement and control for consistent drilling depths.

Product Recommendations:

5. Corded Magnetic Drill Presses

Corded magnetic drill presses combine the portability of a handheld drill with the stability and precision of a stationary drill press. These versatile machines use powerful magnets to secure the drill to the workpiece, allowing for drilling on vertical, horizontal, and overhead surfaces.

Typical Applications:

- Structural Steel Fabrication: Ideal for drilling precise holes in structural steel beams, columns, and plates for construction and fabrication projects.

- Pipe Fabrication: Essential for drilling holes in metal pipes and tubing for plumbing, HVAC, and mechanical installations.

- Shipbuilding: Critical for drilling holes in ship hulls, decks, and structural components during shipbuilding and repair.

- Bridge Construction: Used for drilling holes in steel girders, bridge components, and infrastructure for bridge construction and maintenance.

- Manufacturing: Suitable for drilling holes in metal parts and components in manufacturing facilities and machine shops.

Top 5 Reasons to Use Corded Magnetic Drill Presses:

- Portability: Corded magnetic drill presses are lightweight and portable, allowing for drilling in tight spaces and remote locations.

- Stability: Powerful magnets secure the drill to the workpiece, providing stability and preventing movement during drilling.

- Versatility: Can drill holes on vertical, horizontal, and overhead surfaces, offering flexibility for various drilling applications.

- Precision: Features precise depth control and alignment adjustments for accurate drilling results.

- Efficiency: Saves time and labor compared to handheld drills by offering stable and precise drilling performance.

Top 10 FAQs and Answers:

- Q: How do corded magnetic drill presses work? A: Corded magnetic drill presses use powerful magnets to secure the drill to the workpiece, allowing for stable drilling on vertical, horizontal, and overhead surfaces.

- Q: Can I use corded magnetic drill presses for tapping threads? A: Yes, with the addition of a tapping attachment or tapping head, corded magnetic drill presses can be used for tapping operations.

- Q: What types of drill bits can I use with a corded magnetic drill press? A: Corded magnetic drill presses can accommodate various types of drill bits, including twist drills, annular cutters, and hole saws.

- Q: How do I adjust the drilling speed on a corded magnetic drill press? A: Most corded magnetic drill presses feature adjustable speed settings either through a variable speed trigger or electronic controls.

- Q: Can I use coolant with a corded magnetic drill press for metal drilling? A: Yes, coolant can be used to lubricate and cool the drill bit during metal drilling operations, reducing heat and extending tool life.

- Q: How do I maintain a corded magnetic drill press? A: Regular cleaning, lubrication of moving parts, and inspection of magnets and controls are essential maintenance tasks.

- Q: Can I use corded magnetic drill presses for drilling non-metallic materials? A: While primarily designed for metal drilling, corded magnetic drill presses can also drill non-metallic materials like wood and plastic with the appropriate drill bits.

- Q: Can I use corded magnetic drill presses for drilling underwater? A: Yes, certain corded magnetic drill presses are designed for underwater drilling applications, such as marine construction and repair.

- Q: Are there any safety precautions I should take when using a corded magnetic drill press? A: Always wear safety glasses, secure workpieces properly, and ensure the drill press is properly grounded to prevent electrical hazards.

- Q: Can I use corded magnetic drill presses for overhead drilling? A: Yes, corded magnetic drill presses are designed to drill on vertical, horizontal, and overhead surfaces, providing versatility for various drilling applications.

Top 5 Product Add-Ons:

- Annular Cutters: Specifically designed for use with magnetic drill presses, annular cutters provide faster and more efficient drilling in metal.

- Coolant Systems: Helps lubricate and cool the drill bit during metal drilling operations for extended tool life and improved cutting performance.

- Pilot Pins: Ensures accurate hole alignment and prevents walking or drifting during the initial stages of drilling.

- Magnetic Drill Press Adapters: Allows for mounting additional accessories like drill guides, rotary tables, and tapping heads to enhance the functionality of the magnetic drill press.

- Carrying Cases: Provides convenient storage and transportation for the magnetic drill press and accessories, ensuring they remain organized and protected during travel.

Product Recommendations:

6. Cordless Magnetic Drill Presses

Cordless magnetic drill presses offer the ultimate portability and freedom of movement for drilling tasks in remote locations and job sites without access to electricity. These battery-powered machines use powerful magnets to secure the drill to the workpiece, providing stability and precision.

Typical Applications:

- Construction Sites: Ideal for drilling holes in structural steel, beams, and columns during construction and fabrication.

- Remote Locations: Essential for drilling tasks in remote locations or areas without access to electricity, such as outdoor construction sites and oil rigs.

- Maintenance & Repair: Handy for onsite repairs, installations, and maintenance tasks where access to a power source is limited.

- Metal Fabrication: Used for drilling holes in metal plates, pipes, and components in fabrication shops and manufacturing facilities.

- Automotive Repair: Critical for drilling holes in automotive frames, chassis, and components during repair and restoration projects.

Top 5 Reasons to Use Cordless Magnetic Drill Presses:

- Portability: Cordless magnetic drill presses are completely portable and do not require access to electricity, allowing for drilling in remote locations and outdoor environments.

- Convenience: No need for cumbersome power cords or generators, making cordless magnetic drill presses easy to transport and set up.

- Versatility: Can drill holes on vertical, horizontal, and overhead surfaces, offering flexibility for various drilling applications.

- Efficiency: Saves time and labor compared to manual drilling methods by offering stable and precise drilling performance without the need for a stationary drill press.

- Independence: Provides the freedom to work in areas without access to electricity, ensuring uninterrupted drilling operations in remote locations.

Top 10 FAQs and Answers:

- Q: How long does the battery last on a cordless magnetic drill press? A: Battery life varies depending on usage and battery capacity but typically ranges from several hours to a full day of continuous drilling.

- Q: Can I use cordless magnetic drill presses for tapping threads? A: Yes, with the addition of a tapping attachment or tapping head, cordless magnetic drill presses can be used for tapping operations.

- Q: What types of drill bits can I use with a cordless magnetic drill press? A: Cordless magnetic drill presses can accommodate various types of drill bits, including twist drills, annular cutters, and hole saws.

- Q: How long does it take to recharge the battery on a cordless magnetic drill press? A: Charging times vary depending on the battery capacity and charger specifications but typically range from a few hours to overnight.

- Q: Can I use coolant with a cordless magnetic drill press for metal drilling? A: Yes, coolant can be used to lubricate and cool the drill bit during metal drilling operations, reducing heat and extending tool life.

- Q: How do I maintain a cordless magnetic drill press? A: Regular cleaning, lubrication of moving parts, and inspection of batteries and chargers are essential maintenance tasks.

- Q: Are cordless magnetic drill presses as powerful as corded models? A: While cordless magnetic drill presses may not offer the same level of power as corded models, they provide sufficient torque and drilling capacity for most applications.

- Q: Can I use cordless magnetic drill presses for drilling non-metallic materials? A: Yes, cordless magnetic drill presses can drill non-metallic materials like wood and plastic with the appropriate drill bits.

- Q: Are there any safety precautions I should take when using a cordless magnetic drill press? A: Always wear safety glasses, secure workpieces properly, and follow manufacturer instructions for safe operation of the drill press.

- Q: Can I use cordless magnetic drill presses for overhead drilling? A: Yes, cordless magnetic drill presses are designed to drill on vertical, horizontal, and overhead surfaces, providing versatility for various drilling applications.

Top 5 Product Add-Ons:

- Extra Batteries: Provides backup power for extended drilling sessions without the need to wait for recharging.

- Battery Chargers: Allows for simultaneous charging of multiple batteries, ensuring uninterrupted drilling operations.

- Carrying Cases: Provides convenient storage and transportation for the cordless magnetic drill press and accessories, ensuring they remain organized and protected during travel.

- Magnetic Drill Press Adapters: Allows for mounting additional accessories like drill guides, rotary tables, and tapping heads to enhance the functionality of the cordless magnetic drill press.

- Coolant Systems: Helps lubricate and cool the drill bit during metal drilling operations for extended tool life and improved cutting performance.

Product Recommendations:

Final Thoughts

Investing in the right drill press can significantly enhance productivity and efficiency in various industries, from metal fabrication to woodworking and construction. Understanding the different types of drill presses available, their applications, and features is crucial for making an informed purchasing decision. Whether you need the stability and power of a floor-standing drill press or the portability and versatility of a cordless magnetic drill press, there's a solution to meet your specific drilling needs. Remember to prioritize factors such as precision, durability, and ease of use when selecting the perfect drill press for your workshop or job site. With the right equipment and accessories, you can tackle drilling tasks with confidence and precision, saving time and effort in the process.

- Sustainable Power Tool Practices: Energy-Efficiency and Emission Reduction

- Unlock the Power of Precision: 14 Amazing Metalworking Fluid Brands

- A Comprehensive Guide to Metalworking Machines, Applications and Tips and More

- Mastering Metalworking: A Guide to Essential Machines and Tools

- Choosing the Right Metalworking Fluid and Coolant Brands: A Comprehensive Overview

- Veteran Spotlight

- GoVets Solutions

- Buying Guides & Projects

- Shopping Trends

- Prime Contractor Resources

- Business & Entrepreneur Resources

- GoVets Giving

- Online Security and Shopping Safety

- GoVets Top Selling Products

- Veteran Resources

- Product Spotlights

- Technology Updates

- GoVets Medallion Updates

- Government Updates

- GoVets Capabilities

- Press Releases

- Promotion Updates

- Industry Trends