Sustainable Welding Practices: Reducing Emissions and Energy Usage

Introduction

Welding is an essential part of various industries, from construction and manufacturing to automotive repair and artistic sculpture. But like many industrial processes, traditional welding methods can have a significant environmental impact. The good news? There are sustainable welding practices that can help reduce emissions and energy usage without sacrificing quality or efficiency. In this comprehensive guide, we'll explore how you can adopt eco-friendly welding methods and why choosing products from GoVets can make a difference.

The Environmental Impact of Traditional Welding

Welding operations, especially those that are energy-intensive or involve the use of harmful chemicals, can contribute to air pollution, water contamination, and excessive energy usage. Some of the primary environmental concerns include:

- Emissions of harmful gases like carbon dioxide, nitrogen oxides, and volatile organic compounds.

- Use of hazardous materials, such as certain types of welding rods and fluxes.

- High energy consumption, particularly in processes that require preheating or prolonged operation.

Why Go Green in Welding

Adopting sustainable welding practices isn't just good for the planet; it's also beneficial for your bottom line. Here are some compelling reasons to make the shift:

- Reduced Energy Costs: Energy-efficient welding methods can significantly lower your utility bills.

- Environmental Compliance: With increasing environmental regulations, sustainable practices can help you meet legal requirements.

- Public Image: Companies that adopt eco-friendly practices often enjoy a better reputation, which can lead to increased customer loyalty.

Types of Sustainable Welding Tools

The first step in adopting sustainable welding practices is choosing the right tools. These can range from energy-efficient welding machines to eco-friendly welding chemicals. Below, we discuss the types of tools that can make your welding operations more sustainable.

Welding Machines

Modern welding machines come with energy-efficient features like inverter technology, which allows for a more efficient transfer of electricity. Not only do these machines offer better performance, but they also consume less energy compared to traditional transformer-based machines.

- Hyperlink: Welding Machines on GoVets

- Product Block:

-

Lincoln ElectricSpecial Price $16.49 Regular Price $23.09This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $16.29 Regular Price $22.81This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $8.79 Regular Price $14.56This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $16.49 Regular Price $25.55This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $18.49 Regular Price $28.54This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $195.29 Regular Price $306.33This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $210.99 Regular Price $295.39This product is sold in increments of 1

-

Lincoln ElectricSpecial Price $114.79 Regular Price $179.51This product is sold in increments of 1

Welding Cables

Choosing the right welding cable is crucial for efficient energy transfer. Opt for cables with higher conductivity and insulation materials that can withstand high temperatures without emitting harmful gases.

- Hyperlink: Welding Cables on GoVets

- Product Block:

-

ARC SolutionsSpecial Price $6486.29 Regular Price $12284.79This product is sold in increments of 1

-

Lincoln Electric® LN-25X Wire Feeder with CrossLinc Technology & TVT No Flowmeter 15-110 VDC K4267-2ARC SolutionsSpecial Price $6246.79 Regular Price $11831.29This product is sold in increments of 1

-

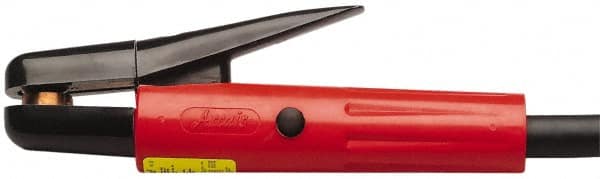

ArcairSpecial Price $1042.79 Regular Price $1149.39This product is sold in increments of 1

-

VictorSpecial Price $838.79 Regular Price $1325.68This product is sold in increments of 1

-

VictorSpecial Price $1148.79 Regular Price $1608.31This product is sold in increments of 1

-

VictorSpecial Price $579.49 Regular Price $811.29This product is sold in increments of 1

-

VictorSpecial Price $372.29 Regular Price $521.21This product is sold in increments of 1

-

VictorSpecial Price $473.29 Regular Price $662.61This product is sold in increments of 1

Welding Chemicals

From anti-spatter to flux, the chemicals used in welding can have an environmental impact. Opt for products that are non-toxic and biodegradable.

- Hyperlink: Welding Chemicals on GoVets

- Product Block:

-

GenericSpecial Price $174.49 Regular Price $259.19This product is sold in increments of 1

-

Weld-AidSpecial Price $167.29 Regular Price $316.99This product is sold in increments of 1

-

WalterSpecial Price $7687.29 Regular Price $7971.01This product is sold in increments of 1

-

WalterSpecial Price $4214.49 Regular Price $4394.29This product is sold in increments of 1

-

CantescoSpecial Price $119.99 Regular Price $198.94This product is sold in increments of 1

-

CantescoSpecial Price $26.99 Regular Price $47.71This product is sold in increments of 1

-

CantescoSpecial Price $1176.49 Regular Price $1723.12This product is sold in increments of 1

-

KesterSpecial Price $186.79 Regular Price $187.73This product is sold in increments of 1

Welding Goggles and Safety Gear

While not directly related to emissions or energy usage, using eco-friendly safety gear made from sustainable materials can contribute to your overall green welding initiative.

- Hyperlink: Welding Goggles, Gloves and Safety Gear on GoVets

- Product Block:

-

North SafetySpecial Price $41.49 Regular Price $78.79This product is sold in increments of 1

-

AccuformNMCSpecial Price $8.29 Regular Price $9.89This product is sold in increments of 1

-

AccuformNMCSpecial Price $20.29 Regular Price $26.3This product is sold in increments of 1

-

AccuformNMCSpecial Price $10.49 Regular Price $13.38This product is sold in increments of 1

-

Continental ContiTechSpecial Price $301.79 Regular Price $341.2This product is sold in increments of 1

-

Continental ContiTechSpecial Price $209.99 Regular Price $237.87This product is sold in increments of 1

-

Smith/MillerSpecial Price $234.29 Regular Price $367.77This product is sold in increments of 1

-

Smith/MillerSpecial Price $469.79 Regular Price $741This product is sold in increments of 1

Fume Extraction Systems

These systems help in capturing welding fumes right at the source, reducing air pollution in the work environment. They are a must for sustainable welding operations.

- Hyperlink: Fume Extraction Systems on GoVets

- Product Block:

Welding Helmets

Choose helmets made from sustainable materials. Modern helmets also come with auto-darkening features that reduce the need for flipping the helmet up and down, thereby reducing the duration of the welding process and saving energy.

- Hyperlink: Welding Helmets on GoVets

- Product Block:

-

Sellstrom

Special Price

$90.99

Regular Price

$131.29

This product is sold in increments of 1

-

Sellstrom

Special Price

$43.99

Regular Price

$45.04

This product is sold in increments of 1

-

Fibre-Metal

Special Price

$11.29

Regular Price

$25.91

This product is sold in increments of 1

-

Jackson Safety

Special Price

$38.49

Regular Price

$53.89

This product is sold in increments of 1

-

North

Special Price

$9.49

Regular Price

$12.79

This product is sold in increments of 1

-

Jackson Safety

Special Price

$680.29

Regular Price

$791.59

This product is sold in increments of 1

-

Allegro

Special Price

$2493.79

Regular Price

$4066.95

This product is sold in increments of 1

-

Miller

Special Price

$8.29

Regular Price

$11.61

This product is sold in increments of 1

Respirators

Using respirators with replaceable filters can help in reducing waste. Opt for eco-friendly filters that can be recycled.

- Hyperlink: Respirators on GoVets

- Product Block:

-

Pyramex Safety ProductsSpecial Price $51.79 Regular Price $98.29This product is sold in increments of 1

-

Sundstrom SafetySpecial Price $9.29 Regular Price $17.79This product is sold in increments of 1

-

RpbSpecial Price $1007.79 Regular Price $1908.79This product is sold in increments of 1

-

RPBSpecial Price $77.79 Regular Price $147.49This product is sold in increments of 1

-

RPBSpecial Price $59.99 Regular Price $113.79This product is sold in increments of 1

-

RPBSpecial Price $58.29 Regular Price $110.49This product is sold in increments of 1

-

RPBSpecial Price $58.29 Regular Price $110.49This product is sold in increments of 1

-

RPBSpecial Price $58.29 Regular Price $110.49This product is sold in increments of 1

Absolutely, let's delve deeper into the topic of top techniques for sustainable welding.

Top Techniques for Sustainable Welding

Welding is an indispensable part of various industries—from automotive and aerospace to construction and manufacturing. However, traditional welding techniques often involve high energy consumption and produce emissions that could be harmful to both the welder and the environment. With the rising awareness of environmental sustainability, many are looking for ways to make welding more eco-friendly without compromising on efficiency or quality. In this comprehensive guide, we explore some top techniques for sustainable welding that can help you achieve just that.

Low Energy Welding Methods

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding, commonly known as MIG welding, uses a continuous wire feed as an electrode and is shielded by an externally supplied gas. This method is known for its efficiency and is widely used in both industrial and home-based settings.

Advantages:

- Reduced Energy Consumption: GMAW is quicker than traditional stick welding, allowing you to complete jobs in less time and thereby consuming less energy.

- Lower Emissions: Because the shielding gas protects the arc, there's less chance of contamination, leading to fewer emissions.

- Less Waste: GMAW allows for better control over the weld, reducing the amount of waste material.

Tungsten Inert Gas (TIG) Welding

TIG welding uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by an inert shielding gas like argon or helium.

Advantages:

- Precision: TIG welding offers greater control, allowing for stronger, higher-quality welds.

- Versatility: It's suitable for more types of metals compared to other welding methods.

- Environmentally Friendly: With fewer emissions and less splatter, TIG welding is generally considered more eco-friendly.

Use of Welding Robots

Efficiency and Precision

Welding robots are programmed to perform tasks with extreme accuracy and speed. This not only ensures a high-quality weld but also significantly reduces the amount of wasted material, leading to a more sustainable process overall.

Advantages:

- Reduced Material Waste: Robots can be programmed to use the exact amount of material needed, minimizing waste.

- Energy Savings: Faster welding times mean less energy consumption.

- Consistency: Robots offer a level of consistency that's hard to achieve manually, ensuring every weld is as efficient as possible.

Initial Investment vs. Long-Term Savings

Though the initial cost of investing in robotic welding systems can be high, the long-term benefits are substantial. Reduced waste and quicker operation times can result in significant cost savings over time. Additionally, the consistent quality of the welds can lead to less rework, further saving materials and energy.

Safety and Precautions

Sustainable Safety Gear

Incorporating safety measures is crucial for any welding operation. When it comes to sustainable welding, even your choice of safety gear can make a difference. Opting for gear made from eco-friendly, sustainable materials can contribute to your overall sustainability goals.

Advantages:

- Reduced Carbon Footprint: Gear made from recycled or sustainable materials helps in reducing your overall carbon footprint.

- Health Benefits: Eco-friendly materials are often free from harmful chemicals that could be detrimental to the welder's health.

Proper Ventilation and Fume Management

Ventilation is a key aspect of welding safety. Proper ventilation systems can prevent the build-up of harmful fumes and gases, protecting both the welder and the environment.

Advantages:

- Reduced Air Pollution: A good ventilation system can capture and filter out harmful fumes, contributing to cleaner air.

- Worker Safety: Proper ventilation ensures a safer work environment by reducing the inhalation of harmful fumes.

Wrapping It Up

Sustainable welding is more than just a trend; it's a necessary shift in how we think about manufacturing and construction. By adopting low-energy welding methods like GMAW and TIG, investing in robotic systems for efficiency, and prioritizing safety with sustainable gear and proper ventilation, we can make significant strides toward more eco-friendly welding practices. These sustainable techniques offer a win-win, benefiting both the environment and the bottom line, proving that going green in welding is not just feasible but highly advantageous.

How to Make the Transition

Transitioning to sustainable welding practices involves a multi-step process:

- Audit your current practices to identify areas for improvement.

- Invest in energy-efficient welding machines and eco-friendly supplies.

- Train your team in sustainable welding techniques.

- Monitor and adjust your practices as needed for continuous improvement.

Why Choose GoVets for Your Sustainable Welding Needs

GoVets offers a wide range of welding products that align with sustainable practices. As a veteran-owned business, we are committed to social responsibility, contributing a portion of each sale to veteran non-profit causes. Our BBB Accreditation and various certifications make us a trusted choice for all your welding needs.

Conclusion

Adopting sustainable welding practices is not only beneficial for the environment but also cost-effective in the long run. Whether you're an individual welder or a large enterprise, making the shift to greener methods is both achievable and rewarding. With GoVets as your go-to source for sustainable welding supplies, you're already on the right path to making a difference.

- Veteran Spotlight

- GoVets Solutions

- Buying Guides & Projects

- Shopping Trends

- Prime Contractor Resources

- Business & Entrepreneur Resources

- GoVets Giving

- Online Security and Shopping Safety

- GoVets Top Selling Products

- Veteran Resources

- Product Spotlights

- Technology Updates

- GoVets Medallion Updates

- Government Updates

- GoVets Capabilities

- Press Releases

- Promotion Updates

- Industry Trends