Mastering Workspace Efficiency: The Ultimate Guide to Choosing the Right Platform Solutions for Every Need

Overview

Welcome to your comprehensive guide to a range of versatile platform solutions! Whether you're in need of configurable platforms, forklift work platforms, or spill containment solutions, we've got you covered. In this guide, we'll delve into various categories of platforms, providing detailed insights, top applications, reasons to use each type, FAQs, recommended add-on products, and expert product recommendations. So, let's dive in and explore the world of platform solutions that cater to a diverse array of needs.

- Configurable Platform Units

- Configurable Turn Platforms

- Forklift Work Platforms

- Guard and Viewing Platforms

- Mezzanine Platforms

- Platform Lifts

- Platform Trucks

- Powered Platform Trucks

- Rolling & Wall Mounted Ladders & Platforms

- Spill Containment Platform and Pallet Ramps

- Spill Pallets, Sumps, Platforms & Basins

- Work Platforms

- Platform Stepladders

1. Configurable Platform Units

Configurable platform units offer adaptable solutions for various elevated needs, providing stability and safety in diverse environments.

Top Applications:

- Warehousing and distribution centers

- Manufacturing facilities

- Construction sites

- Maintenance and repair tasks

- Retail and commercial settings

Top 5 Reasons to Use Configurable Platform Units:

- Versatility in configuration for different tasks

- Enhanced safety features for elevated work

- Increased efficiency in accessing elevated areas

- Durable construction for long-term use

- Easy assembly and disassembly for portability

Top 10 FAQs and Answers:

- Are configurable platform units suitable for outdoor use? Yes, many units are designed for both indoor and outdoor use, with weather-resistant materials.

- What is the weight capacity of these platforms? Weight capacities vary depending on the model, ranging from 250 lbs to 1000 lbs.

- Can multiple units be connected to create larger platforms? Yes, many units feature modular designs that allow for easy connection.

- Are guardrails included with configurable platform units? Some models come with integrated guardrails, while others offer them as optional add-ons.

- Do these platforms comply with safety regulations? Yes, most units are designed to meet or exceed safety standards such as OSHA and ANSI.

- Are there options for platforms with adjustable heights? Yes, many models feature adjustable legs or platforms for added flexibility.

- Can these platforms be easily transported between locations? Yes, most units are designed to be lightweight and portable for easy transport.

- Are there options for platforms with integrated tool trays or holders? Yes, some models come with built-in tool trays or holders for added convenience.

- What are the primary materials used in construction? Common materials include aluminum, steel, and fiberglass, chosen for their durability and strength.

- Are there options for platforms with slim fold designs for compact storage? Yes, some models feature slim fold designs that allow for easy storage in tight spaces.

Top 5 Product Add-Ons:

- Safety harnesses and lanyards

- Stabilizing outriggers for increased stability

- Platform extensions for expanded workspace

- Tool trays and holders for convenient access to tools

- Platform casters for enhanced mobility

Product Recommendation:

Explore a variety of Configurable Platform Units here. Shop Now!

2. Configurable Turn Platforms

Configurable turn platforms offer the flexibility to rotate and adjust, providing ergonomic solutions for accessing hard-to-reach areas.

Top Applications:

- Aircraft maintenance and repair

- Automotive workshops

- Industrial manufacturing

- Utility and telecommunications maintenance

- Retail and warehouse environments

Top 5 Reasons to Use Configurable Turn Platforms:

- 360-degree rotation for maximum accessibility

- Adjustable height and angle for ergonomic positioning

- Compact design for use in confined spaces

- Durable construction for long-lasting reliability

- Versatile configurations to suit various tasks

Top 10 FAQs and Answers:

- What is the maximum weight capacity of turn platforms? Weight capacities vary depending on the model, ranging from 250 lbs to 1000 lbs.

- Are turn platforms suitable for outdoor use? Yes, many units are designed for both indoor and outdoor applications, with weather-resistant materials.

- Do turn platforms require assembly? Yes, most units require minimal assembly and come with detailed instructions.

- Can turn platforms be locked in position? Yes, many models feature locking mechanisms to secure the platform in place during use.

- Are there options for platforms with non-slip surfaces? Yes, most units come with textured surfaces for enhanced grip and safety.

- Can turn platforms be used on uneven surfaces? Yes, some models feature adjustable legs or stabilizing feet to accommodate uneven terrain.

- Do these platforms come with integrated safety features? Yes, many units include guardrails or safety harness attachment points for added protection.

- Are there options for platforms with built-in tool storage? Yes, some models come with integrated tool trays or holders for convenient access to tools.

- What materials are used in construction? Common materials include aluminum, steel, and fiberglass, chosen for their durability and strength.

- Are there options for platforms with slim fold designs for compact storage? Yes, some models feature slim fold designs that allow for easy storage in tight spaces.

Top 5 Product Add-Ons:

- Safety harnesses and lanyards

- Stabilizing outriggers for increased stability

- Platform extensions for expanded workspace

- Tool trays and holders for convenient access to tools

- Platform casters for enhanced mobility

Product Recommendation:

Discover a range of Configurable Turn Platforms here. Shop Now!

3. Forklift Work Platforms

Forklift work platforms provide safe elevated access for forklift operators, enhancing productivity and safety in warehouse and industrial environments.

Top Applications:

- Order picking and inventory management

- Maintenance and repairs in high areas

- Loading and unloading tasks

- Inspections and quality control

- Stock replenishment and shelving

Top 5 Reasons to Use Forklift Work Platforms:

- Improved safety for elevated tasks

- Increased efficiency in accessing high areas

- Compliance with OSHA regulations for fall protection

- Versatile design compatible with various forklift models

- Durable construction for long-term use

Top 10 FAQs and Answers:

- Are forklift work platforms compatible with all forklift models? Most platforms are designed to be compatible with standard forklifts, but it's essential to check compatibility with specific models.

- What is the maximum weight capacity of these platforms? Weight capacities vary depending on the model, typically ranging from 300 lbs to 1000 lbs.

- Do these platforms require special training for operators? Yes, OSHA regulations require operators to receive training in the safe use of elevated work platforms.

- Are guardrails included with forklift work platforms? Yes, most platforms come with integrated guardrails for added safety.

- Can these platforms be used for outdoor tasks? Yes, many models are suitable for both indoor and outdoor use, with weather-resistant materials.

- Do forklift work platforms require assembly? Yes, most platforms require minimal assembly and come with detailed instructions.

- Can platforms be adjusted to different heights? Some models feature adjustable height settings for added flexibility.

- Are there options for platforms with extended reach capabilities? Yes, some models come with telescoping or extendable platforms for increased reach.

- What materials are used in construction? Common materials include steel, aluminum, and fiberglass, chosen for their strength and durability.

- Do these platforms comply with safety regulations? Yes, most platforms are designed to meet or exceed safety standards such as OSHA and ANSI.

Top 5 Product Add-Ons:

- Safety harnesses and lanyards

- Tool trays and holders for convenient access to tools

- Forklift safety cages for added protection

- Platform extensions for expanded workspace

- Guardrail extensions for increased safety

Product Recommendation:

Explore a variety of Forklift Work Platforms here. Explore Now!

-

PWSpecial Price $798.79 Regular Price $879.54This product is sold in increments of 1

-

VestilSpecial Price $100.99 Regular Price $148.68This product is sold in increments of 1

-

VestilSpecial Price $2247.29 Regular Price $3146.21This product is sold in increments of 1

-

VestilSpecial Price $2504.49 Regular Price $3506.29This product is sold in increments of 1

4. Guard and Viewing Platforms

Guard and viewing platforms offer elevated vantage points for surveillance, inspection, and safety monitoring in industrial and commercial settings.

Top Applications:

- Machine and equipment monitoring

- Security surveillance

- Conveyor line inspection

- Crowd control and event management

- Elevated viewing for sports arenas and theaters

Top 5 Reasons to Use Guard and Viewing Platforms:

- Enhanced safety monitoring for elevated areas

- Improved visibility for surveillance and inspection tasks

- Secure access to restricted areas

- Durable construction for long-term use

- Customizable designs to suit specific requirements

Top 10 FAQs and Answers:

- Are guard and viewing platforms customizable? Yes, many platforms offer customizable options such as size, height, and accessories.

- What is the weight capacity of these platforms? Weight capacities vary depending on the model and configuration, typically ranging from 500 lbs to 2000 lbs.

- Do platforms come with integrated safety features? Yes, most platforms include guardrails, toe boards, and safety gates for added protection.

- Can platforms be installed indoors and outdoors? Yes, platforms are suitable for both indoor and outdoor use, with weather-resistant materials available.

- Do platforms require assembly? Yes, most platforms require assembly, but detailed instructions are provided for easy setup.

- Are there options for platforms with wheelchair accessibility? Yes, some models offer wheelchair-accessible platforms with ramps or lifts for ADA compliance.

- Can platforms be installed on uneven surfaces? Yes, some models feature adjustable legs or leveling feet to accommodate uneven terrain.

- Do platforms comply with safety regulations? Yes, most platforms are designed to meet or exceed safety standards such as OSHA and ANSI.

- Are there options for platforms with built-in seating or shelters? Yes, some models come with integrated seating or shelters for added comfort and protection.

- What materials are used in construction? Common materials include steel, aluminum, and fiberglass, chosen for their durability and strength.

Top 5 Product Add-Ons:

- Access stairs or ladders for easy entry

- Safety gates and barriers for restricted areas

- Weatherproof enclosures for outdoor installations

- Surveillance cameras and monitoring systems

- Anti-fatigue mats for added comfort

Product Recommendation:

Discover a range of Guard and Viewing Platforms here. Learn More!

-

Prime-Line ProductsSpecial Price $29.79 Regular Price $56.49This product is sold in increments of 1

-

Prime-Line ProductsSpecial Price $34.49 Regular Price $65.49This product is sold in increments of 1

-

TargusSpecial Price $83.49This product is sold in increments of 1

-

TargusSpecial Price $32.29 Regular Price $59.1This product is sold in increments of 1

5. Mezzanine Platforms

Mezzanine platforms offer versatile elevated storage and workspace solutions, maximizing vertical space in warehouses and industrial facilities.

Top Applications:

- Additional storage space for inventory

- Office or workspace expansion

- Retail mezzanine levels for displays

- Distribution center picking stations

- Multi-level manufacturing facilities

Top 5 Reasons to Use Mezzanine Platforms:

- Efficient use of vertical space for increased storage capacity

- Customizable designs to suit specific layout requirements

- Quick installation with minimal disruption to operations

- Modular construction for scalability and flexibility

- Compliance with building codes and regulations

Top 10 FAQs and Answers:

- Are mezzanine platforms suitable for seismic zones? Yes, many platforms are designed to meet seismic requirements and regulations.

- What is the load capacity of mezzanine platforms? Load capacities vary depending on the design and configuration, typically ranging from 1000 lbs to 2500 lbs per square foot.

- Do platforms require professional installation? Yes, it's recommended to have platforms installed by trained professionals to ensure safety and compliance.

- Can platforms be integrated with existing building structures? Yes, platforms can be customized to fit seamlessly with existing structures and layouts.

- Do platforms come with guardrails and safety features? Yes, most platforms include integrated guardrails, toe boards, and safety gates for added protection.

- Are there options for platforms with integrated stairs or ladders? Yes, some models come with built-in access stairs or ladders for easy entry and exit.

- Can platforms be customized to specific dimensions? Yes, platforms can be customized in terms of size, height, and layout to fit the space available.

- What materials are used in construction? Common materials include steel, aluminum, and fiberglass, chosen for their durability and strength.

- Do platforms comply with fire safety regulations? Yes, platforms are designed to meet fire safety regulations and can be equipped with fire suppression systems if required.

- Are platforms suitable for cleanroom environments? Yes, platforms can be designed to meet cleanroom standards with appropriate materials and finishes.

Top 5 Product Add-Ons:

- Access stairs or ladders for easy entry

- Safety gates and barriers for restricted areas

- Pallet gates for safe loading and unloading

- Handrails and kickplates for added safety

- Shelving and racking systems for efficient storage

Product Recommendation:

Explore a variety of Mezzanine Platforms here. Shop Now!

-

VestilSpecial Price $3030.29 Regular Price $4069.77This product is sold in increments of 1

-

VestilSpecial Price $3098.29 Regular Price $4078.93This product is sold in increments of 1

-

VestilSpecial Price $2761.29 Regular Price $3648.39This product is sold in increments of 1

-

VestilSpecial Price $2611.99 Regular Price $4239.33This product is sold in increments of 1

6. Platform Lifts

Platform lifts offer vertical transportation solutions for materials, goods, and personnel, providing accessibility and efficiency in various settings.

Top Applications:

- Loading docks and warehouses

- Retail stores for stock replenishment

- Manufacturing facilities for production lines

- Hospitals and healthcare facilities

- Accessibility in commercial buildings

Top 5 Reasons to Use Platform Lifts:

- Versatile lifting capabilities for diverse applications

- Increased efficiency in material handling and transportation

- ADA-compliant accessibility for buildings and facilities

- Customizable designs to fit specific space requirements

- Safety features for personnel protection

Top 10 FAQs and Answers:

- What types of platform lifts are available? Platform lifts come in various configurations, including hydraulic, scissor, and vertical mast lifts.

- What is the lifting capacity of platform lifts? Lifting capacities vary depending on the model and configuration, ranging from 500 lbs to 10,000 lbs or more.

- Do platform lifts require professional installation? Yes, it's recommended to have lifts installed by trained professionals to ensure safety and compliance.

- Can platform lifts be used outdoors? Yes, some models are designed for outdoor use, with weather-resistant materials and finishes.

- Do lifts come with safety features for personnel? Yes, most lifts include safety features such as guardrails, safety gates, and emergency stop buttons.

- Are platform lifts suitable for use in cleanroom environments? Yes, some models are designed to meet cleanroom standards with appropriate materials and finishes.

- Do platform lifts require regular maintenance? Yes, regular maintenance is essential to ensure optimal performance and safety of lifts.

- Can lifts be customized for specific applications? Yes, lifts can be customized in terms of size, capacity, and features to meet specific requirements.

- What power sources are available for lifts? Lifts can be powered by electricity, battery, or pneumatic systems, depending on the application and environment.

- Are there options for lifts with remote control operation? Yes, some models come with remote control operation for added convenience and flexibility.

Top 5 Product Add-Ons:

- Platform extensions for increased workspace

- Safety enclosures for personnel protection

- Traffic lights and alarms for enhanced safety

- Ramp kits for easy loading and unloading

- Platform gates for secure access control

Product Recommendation:

Discover a range of Platform Lifts here. Shop Now!

-

Little GiantSpecial Price $107.79 Regular Price $204.29This product is sold in increments of 1

-

CR Daniels DanduxSpecial Price $355.29 Regular Price $672.99This product is sold in increments of 1

-

CR Daniels DanduxSpecial Price $344.99 Regular Price $653.49This product is sold in increments of 1

-

CR Daniels DanduxSpecial Price $365.49 Regular Price $692.29This product is sold in increments of 1

7. Platform Trucks

Platform trucks are versatile tools that streamline material handling in various settings. They offer effortless transportation of goods and equipment, making them ideal for diverse applications.

Top Applications:

- Warehouses and distribution centers

- Manufacturing facilities and shop floors

- Retail and commercial environments

- Hospitals and healthcare settings

- Construction and job sites

Top 5 Reasons to Use Platform Trucks:

- Increased productivity and efficiency in material transportation

- Reduced risk of injury from manual lifting and carrying

- Versatile designs to accommodate different load types and sizes

- Durable construction for heavy-duty use and longevity

- Options for custom configurations to meet specific needs.

Top 10 FAQs and Answers:

- Can platform trucks handle heavy loads? Yes, they come in various weight capacities to suit different requirements.

- What is the difference between a platform truck and a hand truck? Platform trucks have a flat base with wheels, while hand trucks often have two wheels and an upright frame for moving taller items.

- Are platform trucks easy to maneuver? Yes, many models feature swivel casters for smooth movement in tight spaces.

- Do platform trucks have any safety features? Some models have brakes, non-slip surfaces, and ergonomic handles to enhance safety.

- Do platform trucks come in different sizes or materials? Yes, they're available in a wide range of sizes and materials such as steel, aluminum, and wood.

- Can platform trucks be used outdoors? Outdoor-rated models with weather-resistant materials are available.

- Can platform trucks be modified? Yes, some manufacturers offer custom options like drop sides and additional shelving.

- Are platform trucks difficult to assemble? Assembly difficulty varies, but many models are simple to put together.

- What factors should be considered when choosing a truck? Consider the load capacity, maneuverability, and material type that best suits your needs.

- Where can platform trucks be purchased? They're available at industrial supply stores, material handling equipment retailers, and online.

Product Recommendation:

Browse a wide selection of Platform Trucks here. Shop Now!

8. Powered Platform Trucks

When you need additional power for transporting heavy loads, powered platform trucks take the strain away. They boost efficiency and safety in industries with demanding material handling requirements.

Top Applications:

- Large warehouses and distribution centers with long distances to cover

- Manufacturing facilities with heavy machinery or materials

- Airports for baggage and cargo transportation

- Hospitals for moving equipment and supplies

- Construction sites for transporting heavy materials or tools

Top 5 Reasons to Use Powered Platform Trucks:

- Significantly increase productivity and reduce labor intensity

- Minimize worker fatigue and risk of musculoskeletal injuries

- Effortlessly navigate inclines and ramps

- Electric or battery-powered models offer quiet and emission-free operation

- Durable construction for demanding environments

Top 10 FAQs and Answers:

- What types of power sources are used? Powered platform trucks are commonly electric-, battery-, or gasoline-powered.

- Do they require special operator training? Yes, operators should receive training in safe operation, load limits, and maneuvering.

- Are powered platform trucks suitable for uneven terrain? Some models are designed for rough surfaces, while others are best on smooth floors.

- What are the safety features to look for? Consider emergency stops, obstacle sensors, anti-tip systems, and speed limiters.

- Can powered platform trucks be used on inclines? Yes, but check the manufacturer's ratings for safe incline operation.

- How long does the battery last in a powered platform truck? Battery life depends on factors like usage, load, and model. Consult the manufacturer's specifications.

- What is the typical maintenance required for powered platform trucks? Regular maintenance includes checking brakes, tires, electrical systems, and fluid levels (if applicable).

- Are there different sizes and capacities for powered platform trucks? Yes, they come in a range of sizes and weight capacities to suit various needs.

- Can powered platform trucks be customized? Some manufacturers may offer custom options like additional lighting, storage compartments, or attachments.

- What is the average lifespan of a powered platform truck? With proper maintenance, powered platform trucks can last for many years.

Product Recommendation:

Discover efficient Powered Platform Trucks here. Shop Til You Drop!

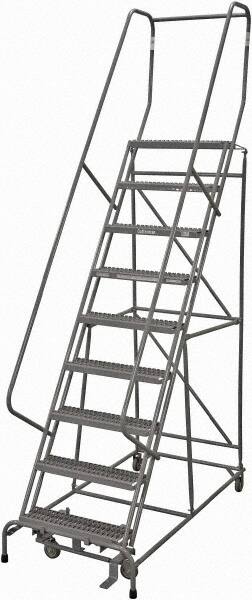

9. Rolling & Wall-Mounted Ladders & Platforms

Rolling and wall-mounted ladders and platforms offer versatile solutions for accessing elevated areas in various industrial, commercial, and maintenance settings with a focus on space saving.

Top Applications:

- Warehouses and stockrooms for inventory access

- Manufacturing facilities for machine maintenance

- Retail environments for stocking and display adjustments

- Libraries and archives for accessing high shelves

- Construction and maintenance tasks with limited floor space

Top 5 Reasons to Use Rolling & Wall-Mounted Ladders & Platforms:

- Maximize space efficiency with compact storage capabilities

- Provide secure access to high areas with stability features

- Offer flexible solutions for diverse work environments

- Durable construction for long-lasting performance

- Safety features like handrails and non-slip surfaces

Top 10 FAQs and Answers:

- How do rolling ladders work? Rolling ladders have wheels that allow them to move freely, and often feature locking mechanisms for stability.

- What is a wall-mounted ladder? Wall-mounted ladders are permanently fixed to walls, providing vertical access in space-constrained areas.

- What materials are they made of? Aluminum, steel, and fiberglass are common materials for strength and durability.

- Are they safe for outdoor use? Select models may be suitable, but always check for weather-resistant properties.

- What safety features should I consider? Look for handrails, non-slip treads, locking casters (on rolling ladders), and weight capacity ratings.

- Do they require professional installation? Wall-mounted ladders usually require professional installation, while rolling ladders may be assembled by the user.

- Can rolling ladders be used on stairs? No, they're designed for smooth, level surfaces.

- How do I choose the right height? Consider the maximum reach height you need and choose accordingly.

- Are there different styles of wall-mounted or rolling ladders? Yes, they come in various configurations like straight, step, and platform ladders.

- What additional accessories might be useful? Platform extensions, leveling feet, and tool holders can be useful add-ons.

Product Recommendation:

Explore our selection of space-saving Rolling & Wall-Mounted Ladders & Platforms here. Shop Today!

-

CottermanSpecial Price $1736.79 Regular Price $2665.22This product is sold in increments of 1

-

CottermanSpecial Price $2370.79 Regular Price $4017.89This product is sold in increments of 1

-

CottermanSpecial Price $1827.29 Regular Price $3235.71This product is sold in increments of 1

-

CottermanSpecial Price $1488.79 Regular Price $2946.79This product is sold in increments of 1

10. Spill Containment Platform and Pallet Ramps

Spill containment platforms and pallet ramps are crucial for safe and compliant chemical and hazardous material handling, ensuring environmental protection and workplace safety.

Top Applications:

- Chemical and hazardous material storage areas

- Manufacturing facilities handling liquids and chemicals

- Waste management and recycling facilities

- Laboratories with chemical and biological materials

- Loading docks and warehouses

Top 5 Reasons to Use Spill Containment Platforms and Pallet Ramps:

- Prevent spills from entering the environment and protect waterways

- Comply with environmental regulations and prevent costly fines

- Maintain a safe and clean workplace by containing spills

- Provide safe and easy loading and unloading of drums and containers

- Versatile options for various spill prevention needs

Top 10 FAQs and Answers:

- What regulatory standards do spill containment platforms meet? Standards like EPA, SPCC, and OSHA regulations.

- Can they handle different types of chemicals? Choose platforms compatible with the specific chemicals you handle.

- How do I calculate the volume needed? The containment volume should exceed the largest container stored.

- Can pallet ramps be used with forklifts? Yes, choose ramps rated for your forklift's weight capacity.

- Can spill containment platforms be customized? Yes, custom sizes and configurations are often available.

- How often should spill containment equipment be inspected? Conduct routine inspections for cracks, leaks, or wear.

- What materials are commonly used for spill containment equipment? Polyethylene, steel, and fiberglass are common choices.

- Can spill containment platforms be moved? Some models are portable, while others are fixed installations.

- Do pallet ramps come with safety features? Look for non-slip surfaces and raised edges for load security.

- What if a spill occurs? Consult your spill preparedness plan, evacuate if necessary, and utilize spill cleanup equipment.

Product Recommendation:

Find Spill Containment Platforms & Pallet Ramps for safe and compliant operations. Explore Now!

11. Spill Pallets, Sumps, Platforms & Basins

Spill pallets, sumps, platforms, and basins provide comprehensive solutions for secondary spill containment, offering essential protection for safe chemical handling and storage.

Top Applications:

- Chemical and hazardous material storage areas

- Manufacturing facilities with liquid processes

- Workshops and garages for vehicle maintenance

- Paint shops and bodywork facilities

- Printing and industrial facilities

Top 5 Reasons to Use Spill Pallets, Sumps, Platforms & Basins:

- Comply with environmental regulations and prevent costly fines

- Safeguard workplaces from spills and environmental hazards

- Protect waterways and prevent environmental contamination

- Capture and contain leaks from drums, containers, and equipment

- Durable and easy-to-use solutions for diverse spill containment needs

Top 10 FAQs and Answers:

- What's the difference between a spill pallet and a spill platform? Spill pallets are typically lower to the ground for containment, while platforms may offer elevated storage.

- What are spill sumps? Spill sumps are low-lying basins that collect larger spills for easier cleanup and disposal.

- What materials are used for spill containment? High-density polyethylene (HDPE) is a common choice due to its chemical resistance and durability.

- How do I choose the right size spill containment? The size should accommodate the largest container you plan to store, plus additional volume for spill containment (consider industry regulations for required spill capacity).

- Do spill pallets need lids? Not always, but lids can be helpful to control odors, emissions, and prevent rainwater from entering.

- Can I store multiple containers on a spill pallet or platform? Yes, as long as the total volume of the containers does not exceed the spill containment capacity of the pallet or platform.

- Are spill pallets and platforms compatible with a wide range of chemicals? Choose models based on the specific chemicals you're storing. Chemical compatibility charts are often available from manufacturers.

- How do I clean up a spill that has been contained? Refer to the product's safety data sheet (SDS) for proper cleanup procedures and use appropriate PPE.

- Do I need to replace spill containment equipment after a spill? Inspect the equipment for damage. Replace if there are cracks, warping, or signs of chemical degradation.

- How long do spill pallets, sumps, and platforms typically last? With proper care and maintenance, they can provide many years of reliable service.

Product Recommendation:

Discover our comprehensive Spill Pallets, Sumps, Platforms & Basins. Explore Now!

-

JustriteSpecial Price $1395.79 Regular Price $1487.98This product is sold in increments of 1

-

EagleSpecial Price $111.79 Regular Price $161.27This product is sold in increments of 1

-

UltratechSpecial Price $1767.99 Regular Price $2475.19This product is sold in increments of 1

-

UltratechSpecial Price $12474.29 Regular Price $12626.99This product is sold in increments of 1

12. Work Platforms

Work platforms provide temporary elevated work surfaces for various tasks in construction, maintenance, industrial settings, and more. They offer a safe and stable alternative to ladders for overhead jobs.

Top Applications:

- Construction sites for framing, electrical work, and installations

- Maintenance and repair tasks in factories and warehouses

- Tree trimming, landscaping, and window cleaning

- Event production and exhibition setups

- HVAC and electrical maintenance

Top 5 Reasons to Use Work Platforms:

- Increased safety compared to ladders, with guardrails and slip-resistant surfaces

- Improved worker productivity and efficiency for elevated tasks

- Versatility for various applications with a range of platform sizes and heights

- Portability for easy setup and relocation on different worksites

- Durability for long-lasting use on demanding job sites

Top 10 FAQs and Answers:

- What types of work platforms are available? Scissor lifts, aerial lifts, boom lifts, and mobile scaffold platforms are common options.

- What factors should I consider when choosing a work platform? Consider the work height required, weight capacity, portability needs, and indoor/outdoor use.

- Do work platforms require assembly? Some pre-assembled models are available, while others may require partial assembly.

- How do I ensure safe operation of work platforms? Follow the manufacturer's instructions, conduct pre-operation checks, and adhere to weight capacity limits.

- Do I need training to use a work platform? Training is recommended, particularly for complex lifts like boom lifts.

- Can work platforms be used on uneven terrain? Some all-terrain models can handle uneven surfaces, while others are designed for level ground.

Product Recommendation:

Browse our selection of Work Platforms to elevate your next project. Shop Now!

-

BallymoreSpecial Price $616.79 Regular Price $1168.29This product is sold in increments of 1

-

BallymoreSpecial Price $466.49 Regular Price $883.79This product is sold in increments of 1

-

BallymoreSpecial Price $423.79 Regular Price $802.79This product is sold in increments of 1

-

VestilSpecial Price $1231.79 Regular Price $2332.99This product is sold in increments of 1

13. Platform Stepladders

Platform stepladders are essential tools for reaching elevated areas safely and efficiently, offering stability and support for various tasks in industrial, commercial, and residential settings.

Top Applications:

- Warehouse inventory management

- Facility maintenance and repair

- Construction and building projects

- Painting and decorating tasks

- Retail stocking and shelving

Top 5 Reasons to Use Platform Stepladders:

- Enhanced stability with wide, non-slip platforms

- Secure handrails for added safety and support

- Compact and portable design for easy transport and storage

- Adjustable height options for versatility in use

- Durable construction for long-lasting performance

Top 10 FAQs and Answers:

- What materials are platform stepladders made of? Platform stepladders are typically constructed from aluminum, fiberglass, or steel for strength and durability.

- What weight capacity do platform stepladders have? Weight capacities vary depending on the model, ranging from 250 lbs to 500 lbs or more.

- Are platform stepladders OSHA-compliant? Yes, many platform stepladders are designed to meet OSHA standards for workplace safety.

- Can platform stepladders be used on uneven surfaces? Some models feature adjustable legs or leveling feet to accommodate uneven terrain.

- Do platform stepladders come with tool trays or holders? Yes, many platform stepladders include built-in tool trays or holders for convenience.

- Are platform stepladders suitable for outdoor use? Yes, certain models are designed for outdoor use with weather-resistant materials and finishes.

- Can platform stepladders be folded for storage? Yes, most platform stepladders are foldable for compact storage when not in use.

- Do platform stepladders have adjustable heights? Yes, many platform stepladders feature adjustable heights to suit different tasks and users.

- Are there platform stepladders with integrated safety features? Yes, platform stepladders often include safety features such as lockable casters and non-slip treads.

- Can platform stepladders be used by multiple users simultaneously? It's recommended to use platform stepladders by one person at a time to prevent accidents and ensure safety.

Top 5 Product Add-Ons:

- Tool trays and holders for convenient tool storage

- Caster kits for enhanced mobility

- Safety gates for restricted access to platforms

- Platform stabilizers for added stability on uneven surfaces

- Accessory hooks for hanging equipment or supplies

Product Recommendation:

Explore a variety of Platform Stepladders here. Shop Now!

Final Thoughts

As we wrap up this extensive guide on platform solutions, it's clear that the versatility and range of options available can meet the needs of almost any industrial, commercial, or maintenance scenario. From configurable units that adapt to diverse workplace layouts, to robust forklift work platforms designed for heavy-duty operations, each category offers unique benefits that enhance safety, efficiency, and functionality.

Investing in the right platform solution is not just about meeting immediate needs—it's about anticipating the demands of future projects and ensuring that your environment remains safe and productive. Whether you're managing a warehouse, overseeing a construction site, or ensuring compliance with environmental standards, these platforms provide the foundation for a safer and more efficient workspace.

We hope this guide has equipped you with the knowledge to make informed decisions about which platforms best suit your operational needs. Remember, the right platform can significantly impact productivity and safety, making it a crucial investment for any business. Explore our recommendations and add-ons to truly customize your solution and maximize its benefits.

Thank you for joining us on this deep dive into the world of platforms. Whether you're looking to purchase your first platform or upgrade your existing equipment, the perfect solution is just a click away. Explore our selection, consult with experts, and take your business operations to new heights—safely and efficiently.

- Veteran Spotlight

- GoVets Solutions

- Buying Guides & Projects

- Shopping Trends

- Prime Contractor Resources

- Business & Entrepreneur Resources

- GoVets Giving

- Online Security and Shopping Safety

- GoVets Top Selling Products

- Veteran Resources

- Product Spotlights

- Technology Updates

- GoVets Medallion Updates

- Government Updates

- GoVets Capabilities

- Press Releases

- Promotion Updates

- Industry Trends