Mastering Precision: The Comprehensive Guide to Coordinate Measuring Machines

Introduction:

Welcome to the intricate world of Coordinate Measuring Machines (CMMs), a realm where precision meets technology to ensure the highest quality in manufacturing and design. This comprehensive blog delves into the multifaceted aspects of CMMs, from their basic components and operation to their revolutionary impact across various industries. Whether you're a quality control professional, an engineer, or simply curious about the future of precision measurement, join us as we explore the significance, evolution, and indispensable nature of CMMs in today's technology-driven world.

Table of Contents:

Part I - What Are Coordinate Measuring Machines (CMMs)?

-

- Key Components of a CMM

- How CMMs Work

- Applications of CMMs

Part II - The Importance of Coordinate Measuring Machines (CMMs)

-

- Historical Evolution

- Importance of CMMs

- Top 10 Industries Using CMMs and Their Top Uses

Part III - CMM Category Recommendations

-

- CMM Accessories on GoVets

- CMM Clamps on GoVets

- CMM Fixtures on GoVets

- CMM Module & Stylus Kits on GoVets

- CMM Probe & Stylus Modules on GoVets

- CMM Replacement Parts on GoVets

- CMM Styli & Probes on GoVets

- CMM Stylus Adapters on GoVets

- CMM Stylus Extensions on GoVets

- CMM Machines on GoVets

- CMM Styli on GoVets

Part I - What Are Coordinate Measuring Machines (CMMs)?

Coordinate Measuring Machines (CMMs) are sophisticated metrology instruments used for measuring the physical dimensions and geometrical characteristics of objects with exceptional accuracy and precision. They play a vital role in quality control, dimensional analysis, and inspection processes across various industries. CMMs are known for their ability to capture three-dimensional data points, making them indispensable tools in manufacturing, research, and engineering.

1. Key Components of a CMM:

To understand the functionality of CMMs, it's essential to familiarize yourself with their key components:

- Probe or Sensor: The probe or sensor is the part of the CMM that makes physical contact with the object being measured. It can be a mechanical touch probe, a scanning probe, or even a non-contact laser sensor, depending on the specific measurement requirements.

- Coordinate System: CMMs operate within a three-dimensional Cartesian coordinate system (X, Y, and Z axes). The machine's movement is precisely controlled along these axes to position the probe accurately.

- Controller: The controller serves as the brain of the CMM, managing the machine's movements, collecting measurement data, and processing the information for analysis.

- Bridge or Arm: CMMs come in various configurations, such as bridge-type, gantry-type, or portable arms. The bridge or arm holds the probe and allows it to move smoothly in three dimensions.

- Software: Measurement software is a crucial part of CMMs, enabling users to define measurement routines, capture data, and generate reports. Advanced software packages provide powerful analysis and visualization tools.

2. How CMMs Work:

The operation of a CMM involves a series of precise movements and measurements:

- Setup: The object to be measured is securely fixed on the CMM's worktable or fixture.

- Probe Calibration: Before measurement, the probe is calibrated to ensure its accuracy. This calibration compensates for any potential deviations in the probe's dimensions.

- Measurement Planning: Using specialized software, users define the measurement routine, specifying the points, features, or surfaces to be measured.

- Probe Movement: The CMM's controller guides the probe to the specified measurement points. In some cases, the probe may make contact with the object's surface, while in others, non-contact methods like laser scanning are employed.

- Data Capture: As the probe moves, it collects data points, recording the object's coordinates in three dimensions. This data is stored for further analysis.

- Analysis: The captured data is analyzed to determine dimensional accuracy, deviations from design specifications, and other relevant parameters.

- Reporting: Measurement software generates comprehensive reports, including graphical representations and statistical analyses, for quality control purposes.

3. Applications of CMMs:

Coordinate Measuring Machines find applications in a wide range of industries and fields, including:

- Manufacturing: Ensuring the quality and precision of machined parts, molds, and tooling.

- Aerospace: Inspecting complex aerospace components for precise dimensions and alignments.

- Automotive: Quality control of automotive parts to meet strict tolerances and standards.

- Medical Devices: Verifying the accuracy and consistency of medical implants and devices.

- Electronics: Ensuring the precision of printed circuit boards (PCBs) and electronic components.

- Mold and Die Making: Verifying the molds and dies used in manufacturing processes.

- Energy: Inspecting critical components of energy equipment like turbines and generators.

- Metalworking and Machining: Quality control in metalworking processes and precision machining.

- Plastics: Ensuring the accuracy of plastic components used in various industries.

- Research and Development: Capturing precise measurements for R&D and prototype development.

Section Wrap-Up:

Coordinate Measuring Machines are indispensable tools for industries where accuracy, precision, and quality control are paramount. Their ability to capture three-dimensional data and provide detailed analyses makes them invaluable assets in modern manufacturing and dimensional analysis. As technology continues to advance, CMMs remain at the forefront of metrology, contributing to the production of high-quality products and innovative research and development.

Part II - The Importance of Coordinate Measuring Machines (CMMs)

Coordinate Measuring Machines (CMMs) have revolutionized the world of metrology and quality control. These precision instruments are indispensable in a wide range of industries where accuracy, consistency, and reliability in measurements are critical. Let's delve into the importance, historical evolution, top 10 industries, and typical uses of CMMs.

1. Historical Evolution:

The concept of measuring machines dates back to the 18th century when early devices were used for measuring various mechanical components. However, the modern CMM, as we know it today, emerged in the mid-20th century. The development of computer technology and advancements in mechanical engineering led to the creation of CMMs capable of three-dimensional measurements with incredible precision. Over the decades, CMMs have evolved to incorporate advanced technologies like laser scanning and non-contact probing, further enhancing their capabilities.

2. Importance of CMMs:

- Precision and Accuracy: CMMs offer sub-micron level precision, ensuring that even the tiniest deviations in measurements are detected. This precision is vital for industries where small errors can lead to significant quality issues.

- Efficiency: CMMs streamline measurement processes, reducing the time and labor required for inspections. This efficiency is particularly crucial for high-volume manufacturing.

- Consistency: CMMs provide consistent and repeatable measurements, eliminating human error and ensuring uniform quality across production batches.

- Data Analysis: CMMs generate detailed measurement data that can be analyzed for trends, helping manufacturers make informed decisions for process improvement.

- Complex Geometry Inspection: They excel in inspecting intricate and complex part geometries that are challenging for manual measurement methods.

3. Top 10 Industries Using CMMs and Their Top Uses:

1. Aerospace Industry

-

- Top Use: Inspection of critical aerospace components such as turbine blades, airfoils, and engine parts for precise dimensions and alignment.

- Typical Users: Aerospace manufacturers, maintenance and repair organizations (MROs).

2. Automotive Industry

-

- Top Use: Quality control of automotive components, ensuring tight tolerances in engine parts, body panels, and chassis components.

- Typical Users: Automotive manufacturers, suppliers, and quality control teams.

3. Medical Device Manufacturing

-

- Top Use: Ensuring the precision and quality of medical devices, including implants, surgical instruments, and diagnostic equipment.

- Typical Users: Medical device manufacturers, regulatory bodies, research institutions.

4. Electronics Manufacturing

-

- Top Use: Inspection of printed circuit boards (PCBs), connectors, and electronic components for accuracy and alignment.

- Typical Users: Electronics manufacturers, contract manufacturers, PCB assemblers.

5. Mold and Die Making

-

- Top Use: Verification of mold and die cavities, ensuring they meet design specifications for plastic and metal part production.

- Typical Users: Mold and die manufacturers, injection molding companies.

6. Energy Sector

-

- Top Use: Inspection of critical energy components such as wind turbine blades and gas turbine parts to ensure efficiency and safety.

- Typical Users: Energy equipment manufacturers, renewable energy companies.

7. Metalworking and Machining

-

- Top Use: Quality control of machined parts, including gears, shafts, and precision components for various industries.

- Typical Users: Metalworking shops, machine shops, manufacturers of industrial equipment.

8. Tool and Die Manufacturing

-

- Top Use: Precision measurement of tool and die components, ensuring accuracy in metal stamping and forming operations.

- Typical Users: Tool and die manufacturers, metalworking industries.

9. Plastics Industry

-

- Top Use: Inspection of plastic components and molds for consumer products, automotive parts, and packaging materials.

- Typical Users: Plastic manufacturers, injection molders, product designers.

10. Research and Development (R&D)

-

- Top Use: Exploring new materials and prototypes, capturing precise measurements for product development and innovation.

- Typical Users: Research institutions, product development teams, laboratories.

In each of these industries, CMMs play a pivotal role in maintaining quality standards, reducing production costs, and ensuring compliance with industry regulations. Their versatility and ability to adapt to diverse measurement needs make them indispensable tools for modern manufacturing and quality assurance.

As technology continues to advance, CMMs are likely to become even more sophisticated, further expanding their applications and capabilities. Whether in aerospace, automotive, medical, or any other industry, CMMs remain at the forefront of precision measurement and quality control, shaping the future of manufacturing and innovation.

Part III - CMM Category Recommendations:

Coordinate Measuring Machines (CMMs) play a pivotal role in industries and trades that require precision measurement and quality control. CMMs are highly sophisticated devices used for dimensional measurement and inspection tasks in various industries. To enhance the capabilities of CMMs and ensure accurate measurements, a wide range of accessories, fixtures, modules, and stylus kits are available in the market. In this comprehensive guide, we will explore different categories of CMM accessories and equipment, providing an overview of each category, highlighting typical applications, and offering product recommendations. Whether you are a quality control professional, an engineer, or someone interested in precision measurement tools, this guide will help you navigate the world of CMM accessories with confidence.

1. CMM Accessories on GoVets

Overview: CMM accessories encompass a wide range of products designed to optimize the functionality of Coordinate Measuring Machines. These accessories are essential for enhancing measurement accuracy and efficiency. They include components such as calibration standards, reference spheres, and measurement software.

Top Applications:

- Precision Calibration: CMM accessories are crucial for calibrating CMM machines, ensuring they provide accurate measurements.

- Quality Control: These accessories aid in maintaining consistent quality control processes in manufacturing.

- Research and Development: CMM accessories are used in R&D settings to validate and refine product designs.

Product Recommendations:

-

RenishawSpecial Price $26.99 Regular Price $37.79This product is sold in increments of 1

-

RenishawSpecial Price $524.29 Regular Price $734.01This product is sold in increments of 1

-

PhillipsSpecial Price $2602.99 Regular Price $3549.29This product is sold in increments of 1

-

FowlerSpecial Price $19.79 Regular Price $27.71This product is sold in increments of 1

-

PhillipsSpecial Price $1520.99 Regular Price $1796.14This product is sold in increments of 1

-

PhillipsSpecial Price $3573.49 Regular Price $4151.52This product is sold in increments of 1

-

PhillipsSpecial Price $2949.79 Regular Price $4129.71This product is sold in increments of 1

-

RenishawSpecial Price $4135.29 Regular Price $5789.41This product is sold in increments of 1

2. CMM Clamps on GoVets

Overview: CMM clamps are specialized fixtures used to securely hold workpieces during measurement processes. They come in various shapes and sizes to accommodate different workpiece geometries.

Top Applications:

- Part Inspection: CMM clamps ensure that parts are held firmly in place during inspection, preventing any movement that could affect measurement accuracy.

- Machining Setup: These clamps are used in machining setups to position and secure workpieces.

- Automotive Industry: CMM clamps find extensive use in the automotive industry for inspecting critical components.

Product Recommendations:

-

RenishawSpecial Price $3707.29 Regular Price $5190.21This product is sold in increments of 1

-

RenishawSpecial Price $5390.79 Regular Price $7547.11This product is sold in increments of 1

-

RenishawSpecial Price $4186.99 Regular Price $5861.79This product is sold in increments of 1

-

RenishawSpecial Price $3608.49 Regular Price $5051.89This product is sold in increments of 1

-

RenishawSpecial Price $3736.49 Regular Price $5231.09This product is sold in increments of 1

-

RenishawSpecial Price $2546.99 Regular Price $3565.79This product is sold in increments of 1

-

RenishawSpecial Price $1950.79 Regular Price $2731.11This product is sold in increments of 1

-

RenishawSpecial Price $5236.29 Regular Price $7330.81This product is sold in increments of 1

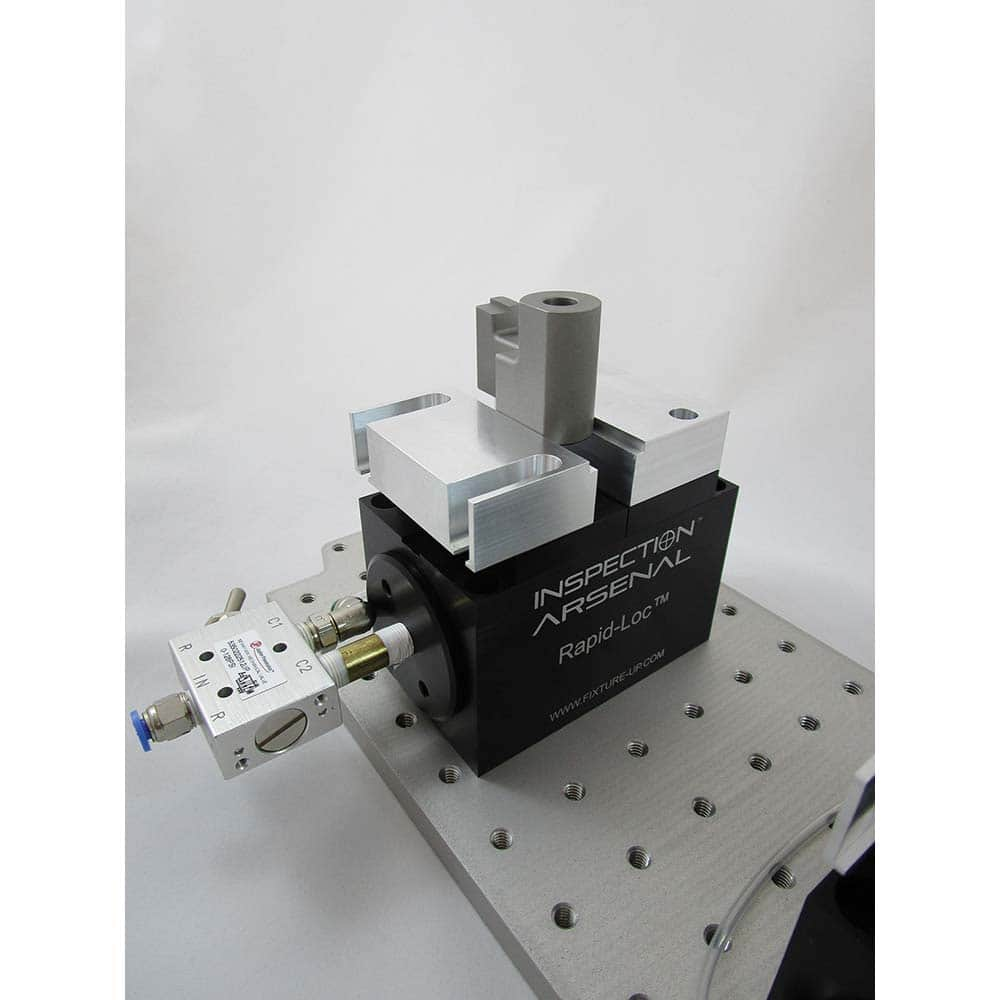

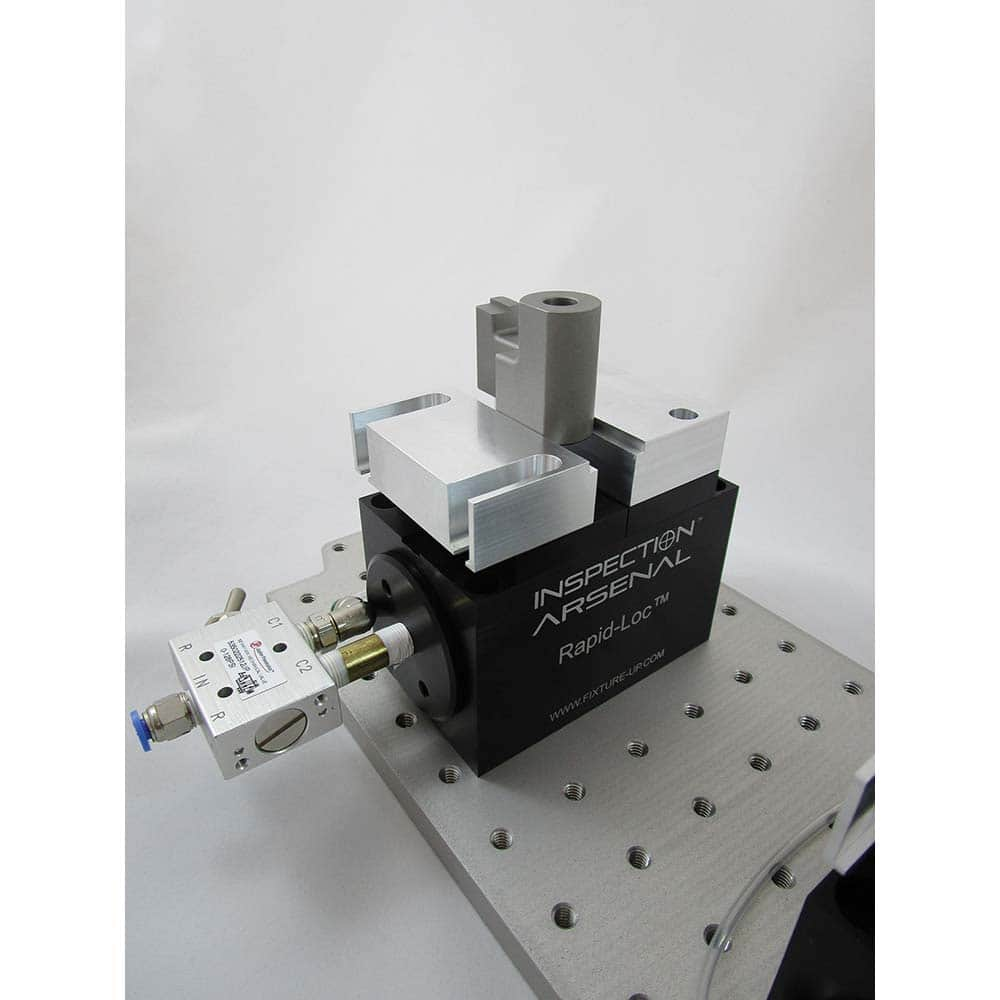

3. CMM Fixtures on GoVets

Overview: CMM fixtures are essential for securely holding and positioning workpieces during measurement. They are designed to accommodate a variety of part geometries.

Top Applications:

- Aerospace Industry: CMM fixtures are extensively used in the aerospace industry for inspecting complex and precision-engineered components.

- Medical Devices: They play a vital role in the quality control of medical devices, ensuring they meet stringent standards.

- Electronics Manufacturing: CMM fixtures are used in electronics manufacturing to inspect circuit boards and components.

Product Recommendations:

-

RenishawSpecial Price $35.99 Regular Price $50.39This product is sold in increments of 1

-

RenishawSpecial Price $166.99 Regular Price $233.79This product is sold in increments of 1

-

RenishawSpecial Price $15.29 Regular Price $21.41This product is sold in increments of 1

-

RenishawSpecial Price $162.99 Regular Price $228.19This product is sold in increments of 1

-

RenishawSpecial Price $156.29 Regular Price $218.81This product is sold in increments of 1

-

RenishawSpecial Price $73.49 Regular Price $102.89This product is sold in increments of 1

-

RenishawSpecial Price $160.29 Regular Price $224.41This product is sold in increments of 1

-

RenishawSpecial Price $35.79 Regular Price $50.11This product is sold in increments of 1

4. CMM Module & Stylus Kits on GoVets

Overview: CMM module and stylus kits are essential for extending the capabilities of your CMM machine. These kits include various modules and stylus configurations for specific measurement tasks.

Top Applications:

- Surface Finish Measurement: Module and stylus kits are used for precise surface finish measurement in industries like automotive and aerospace.

- Complex Geometry Inspection: They enable the measurement of intricate and hard-to-reach geometries.

- Reverse Engineering: CMM modules and stylus kits assist in reverse engineering processes by capturing detailed measurements.

Product Recommendations:

-

SPISpecial Price $475.99 Regular Price $666.39This product is sold in increments of 1

-

RenishawSpecial Price $12393.79 Regular Price $17351.31This product is sold in increments of 1

-

RenishawSpecial Price $14342.49 Regular Price $20079.49This product is sold in increments of 1

-

FowlerSpecial Price $701.79 Regular Price $761.84This product is sold in increments of 1

-

Tesa Brown & SharpeSpecial Price $181.79 Regular Price $181.89This product is sold in increments of 1

-

RenishawSpecial Price $1219.49 Regular Price $1707.29This product is sold in increments of 1

-

RenishawSpecial Price $3296.29 Regular Price $4614.81This product is sold in increments of 1

-

RenishawSpecial Price $6807.49 Regular Price $9530.49This product is sold in increments of 1

5. CMM Probe & Stylus Modules on GoVets

Overview: CMM probe and stylus modules are crucial components for contact measurement on CMM machines. They come in various configurations to suit different measurement needs.

Top Applications:

- Industrial Metrology: Probe and stylus modules are extensively used for measuring complex parts and ensuring they meet precise specifications.

- Automotive Manufacturing: These modules play a key role in quality control processes in the automotive industry.

- Mold and Die Inspection: They are used for inspecting molds and dies, ensuring they meet design tolerances.

Product Recommendations:

-

RenishawSpecial Price $1019.99 Regular Price $1427.99This product is sold in increments of 1

-

RenishawSpecial Price $30925.99 Regular Price $43296.39This product is sold in increments of 1

-

RenishawSpecial Price $27267.79 Regular Price $38174.91This product is sold in increments of 1

-

RenishawSpecial Price $2841.79 Regular Price $3978.51This product is sold in increments of 1

-

RenishawSpecial Price $31.29 Regular Price $43.81This product is sold in increments of 1

-

RenishawSpecial Price $1045.99 Regular Price $1464.39This product is sold in increments of 1

-

RenishawSpecial Price $980.49 Regular Price $1372.69This product is sold in increments of 1

-

RenishawSpecial Price $5635.49 Regular Price $7889.69This product is sold in increments of 1

6. CMM Replacement Parts on GoVets

Overview: CMM replacement parts are essential for maintaining and repairing CMM machines. They include components like bearings, scales, and motors.

Top Applications:

- Preventive Maintenance: Replacement parts are used to perform routine maintenance, ensuring CMM machines operate at peak performance.

- Machine Repairs: In case of breakdowns or malfunctions, these parts are essential for quick repairs.

- Prolonging Machine Life: Using quality replacement parts can extend the lifespan of CMM machines.

Product Recommendations:

-

RenishawSpecial Price $3.29 Regular Price $4.61This product is sold in increments of 1

-

RenishawSpecial Price $40.79 Regular Price $57.11This product is sold in increments of 1

-

RenishawSpecial Price $1042.29 Regular Price $1459.21This product is sold in increments of 1

-

RenishawSpecial Price $3999.79 Regular Price $5599.71This product is sold in increments of 1

-

RenishawSpecial Price $397.29 Regular Price $556.21This product is sold in increments of 1

-

RenishawSpecial Price $490.99 Regular Price $687.39This product is sold in increments of 1

-

RenishawSpecial Price $397.29 Regular Price $556.21This product is sold in increments of 1

-

RenishawSpecial Price $2060.99 Regular Price $2885.39This product is sold in increments of 1

7. CMM Styli & Probes on GoVets

Overview: CMM styli and probes are critical for capturing accurate measurements in contact-based inspections. They come in various shapes and materials to suit different applications.

Top Applications:

- Aerospace Industry: CMM styli and probes are used for inspecting aerospace components, including turbine blades and engine parts.

- Automotive Quality Control: These tools ensure the precision and reliability of automotive components.

- Medical Device Manufacturing: CMM styli and probes play a crucial role in ensuring the quality of medical devices.

Product Recommendations:

-

RenishawSpecial Price $24.49 Regular Price $34.29This product is sold in increments of 1

-

RenishawSpecial Price $280.29 Regular Price $392.41This product is sold in increments of 1

-

RenishawSpecial Price $243.99 Regular Price $341.59This product is sold in increments of 1

-

RenishawSpecial Price $37.99 Regular Price $53.19This product is sold in increments of 1

-

RenishawSpecial Price $91.79 Regular Price $128.51This product is sold in increments of 1

-

RenishawSpecial Price $1207.49 Regular Price $1690.49This product is sold in increments of 1

-

RenishawSpecial Price $105.49 Regular Price $147.69This product is sold in increments of 1

-

RenishawSpecial Price $43.29 Regular Price $60.61This product is sold in increments of 1

8. CMM Stylus Adapters on GoVets

Overview: CMM stylus adapters are designed to connect styli and probes to CMM machines. They provide flexibility in measurement setups.

Top Applications:

- Custom Measurement Configurations: Stylus adapters allow users to create custom measurement configurations to suit specific part geometries.

- Precision Measurement: They enhance the precision of measurements by minimizing deflection and vibration.

- Multi-Sensor Integration: Adapters enable the integration of various sensors for comprehensive measurements.

Product Recommendations:

-

RenishawSpecial Price $1725.49 Regular Price $2415.69This product is sold in increments of 1

-

RenishawSpecial Price $24.29 Regular Price $34.01This product is sold in increments of 1

-

RenishawSpecial Price $145.79 Regular Price $204.11This product is sold in increments of 1

-

SPISpecial Price $53.49 Regular Price $74.89This product is sold in increments of 1

-

SPISpecial Price $26.29 Regular Price $36.81This product is sold in increments of 1

-

SPISpecial Price $28.99 Regular Price $40.59This product is sold in increments of 1

-

SPISpecial Price $37.99 Regular Price $53.19This product is sold in increments of 1

-

SPISpecial Price $30.99 Regular Price $43.39This product is sold in increments of 1

9. CMM Stylus Extensions on GoVets

Overview: CMM stylus extensions are used to extend the reach of styli and probes, allowing measurements in deep or hard-to-reach areas.

Top Applications:

- Complex Geometry Inspection: Stylus extensions enable CMM machines to access intricate and challenging part features.

- Aerospace Components: They are used for inspecting aerospace components with deep recesses and tight tolerances.

- Tool and Die Manufacturing: Stylus extensions play a crucial role in maintaining precision in tool and die production.

Product Recommendations:

-

SPISpecial Price $15.49 Regular Price $21.69This product is sold in increments of 1

-

SPISpecial Price $15.49 Regular Price $21.69This product is sold in increments of 1

-

SPISpecial Price $19.99 Regular Price $20.96This product is sold in increments of 1

-

SPISpecial Price $28.49 Regular Price $39.89This product is sold in increments of 1

-

SPISpecial Price $35.49 Regular Price $49.69This product is sold in increments of 1

-

RenishawSpecial Price $111.49 Regular Price $156.09This product is sold in increments of 1

-

RenishawSpecial Price $60.79 Regular Price $85.11This product is sold in increments of 1

-

RenishawSpecial Price $59.49 Regular Price $83.29This product is sold in increments of 1

10. CMM Machines on GoVets

Overview: CMM machines are the core devices used for precision measurement and inspection tasks. They come in various configurations, including bridge, gantry, and portable CMMs.

Top Applications:

- Aerospace Component Inspection: CMM machines are crucial for verifying the precision of aerospace components.

- Automotive Quality Assurance: They play a vital role in ensuring the quality and performance of automotive parts.

- Medical Device Manufacturing: CMM machines are used to inspect critical components of medical devices.

Product Recommendations:

-

HelmelSpecial Price $60513.29 Regular Price $64533.51This product is sold in increments of 1

-

HelmelSpecial Price $80583.49 Regular Price $97616.56This product is sold in increments of 1

-

HelmelSpecial Price $80299.79 Regular Price $112419.71This product is sold in increments of 1

-

HelmelSpecial Price $79821.99 Regular Price $97008.12This product is sold in increments of 1

-

HelmelSpecial Price $79728.49 Regular Price $91596.03This product is sold in increments of 1

11. CMM Styli on GoVets

CMM styli are essential for contact-based measurements. They come in various shapes and materials to suit different measurement needs.

Top Applications:

- Surface Finish Measurement: CMM styli are used for capturing precise surface finish data.

- Reverse Engineering: They aid in reverse engineering processes by capturing detailed measurements.

- Mold and Die Inspection: Styli are crucial for inspecting molds and dies in manufacturing.

Product Recommendations:

Final Thoughts:

As we conclude our exploration of Coordinate Measuring Machines (CMMs), it's clear that these tools are more than just machines; they're pivotal contributors to the realms of quality control, innovation, and precision engineering. The continuous evolution of CMM technology promises even greater accuracy, efficiency, and adaptability, ensuring that industries worldwide can rely on the highest standards of measurement. Whether you're in aerospace, automotive, medical, or any field where precision is paramount, CMMs stand as guardians of quality, pushing the boundaries of what's possible and shaping the future of manufacturing and design.

- Veteran Spotlight

- GoVets Solutions

- Buying Guides & Projects

- Shopping Trends

- Prime Contractor Resources

- Business & Entrepreneur Resources

- GoVets Giving

- Online Security and Shopping Safety

- GoVets Top Selling Products

- Veteran Resources

- Product Spotlights

- Technology Updates

- GoVets Medallion Updates

- Government Updates

- GoVets Capabilities

- Press Releases

- Promotion Updates

- Industry Trends