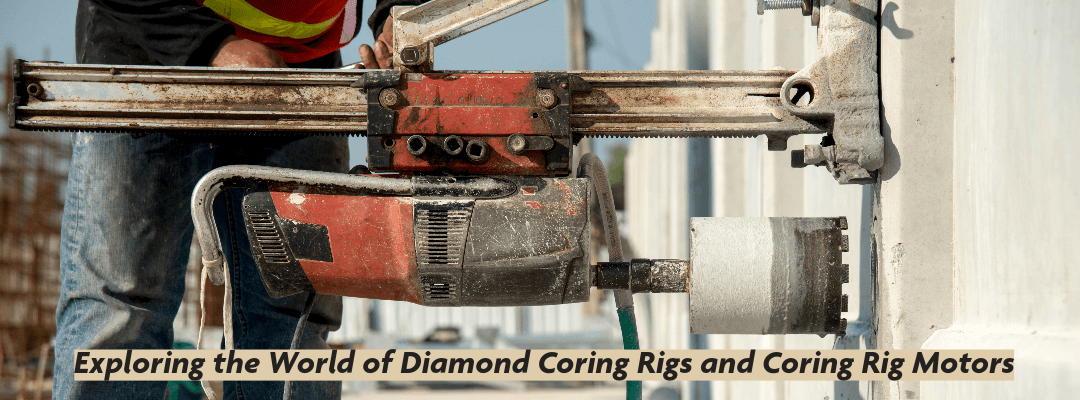

Exploring the World of Diamond Coring Rigs and Coring Rig Motors

Introduction

Diamond coring rigs and coring rig motors are essential tools in the mining and construction industries. These specialized devices allow for the extraction of core samples from the earth, providing valuable data for various applications. This blog post aims to delve deep into the world of diamond coring rigs, exploring their history, applications, and the various products available for purchase.

A Brief History of Diamond Core Drilling

The Invention and Early Use

The journey of diamond core drilling began in 1863 when a French engineer named Rodolphe Leschot invented the diamond core drill. Leschot's invention was initially used for drilling blast holes in the construction of the Mount Cenis tunnel, which connects France and Italy. This was a monumental task that required a tool capable of penetrating the hard rock of the Alpine region. The diamond core drill was up to the task, revolutionizing the way tunnels were constructed.

Interestingly, the concept of using diamonds for drilling isn't entirely modern. The roots of this technology can be traced back to Ancient Egypt, where tubular drills with jeweled edges were used to cut through hard materials like granite and quartz. The Egyptians used these drills for various purposes, including the construction of monuments and sculptures. The idea of using diamonds, one of the hardest known materials, for drilling through other hard substances has been around for millennia, but it was Leschot who brought it into the industrial age

Modern Advancements

Fast forward to today, and diamond core drilling has become an indispensable tool in various industries. It's not just for tunneling through mountains anymore. The technology has evolved to become a standard piece of equipment for the exploration and development of mines. Whether it's gold, coal, or rare earth minerals, diamond core drilling provides an efficient and accurate way to obtain core samples.

But the applications don't stop at mining. The construction industry has also embraced diamond core drilling, especially in the construction of large structures like skyscrapers, bridges, and dams. The ability to drill through reinforced concrete, metal, and other tough materials makes diamond core drilling invaluable in modern construction projects.

Exploration Diamond Drilling

One of the most significant applications of diamond core drilling is in the field of exploration diamond drilling. This specialized drilling method is used extensively in the mining industry to probe the contents of known ore deposits and potential mining sites. The high precision and ability to obtain large, intact core samples make it an ideal choice for exploratory activities.

But the utility of exploration diamond drilling isn't limited to mining. It's also frequently used in the geotechnical engineering industry for foundation testing. Before constructing large structures like bridges or skyscrapers, it's crucial to understand the composition and stability of the ground. Diamond core drilling provides this information, helping engineers make informed decisions about the feasibility and safety of construction projects

In summary, diamond core drilling has come a long way since its invention in the 19th century. From its early use in tunnel construction to its modern applications in mining exploration and building construction, this technology has proven its worth time and again. Its ability to penetrate hard materials, coupled with the precision it offers, makes it an invaluable tool in various industries. As we continue to push the boundaries of engineering and exploration, diamond core drilling will undoubtedly play a significant role in shaping our understanding of the earth and our capabilities to manipulate it.

Coring Rigs

Coring rigs are the unsung heroes of the drilling world. These robust machines are engineered to withstand the rigors of drilling through an array of materials, ranging from the softest soils to the hardest rocks. But what makes them so indispensable? Let's dig deeper into the world of coring rigs.

Importance of Coring Rig Specifications

The specifications of a coring rig are not just numbers; they are critical factors that determine the rig's performance, efficiency, and suitability for a particular job. Here's why each spec matters:

- Power (20 to 50 HP): The horsepower of a coring rig dictates its drilling capabilities. Higher horsepower allows for faster and more efficient drilling, especially in hard materials like granite or reinforced concrete.

- Depth (Up to 2000 meters): The depth to which a rig can drill is crucial for applications like mining exploration, where reaching greater depths could mean the difference between finding a valuable resource or coming up empty-handed.

- Core Diameter (47.6mm to 85mm): The diameter of the core extracted is vital for the quality of samples. Larger diameters provide more material for analysis, which can be crucial in fields like geology and environmental science.

Why Different Specifications Might Be Used

- Shallow vs. Deep Drilling: Rigs with lower horsepower and depth capabilities are generally used for shallow drilling tasks like soil sampling or archaeological digs. On the other hand, rigs with higher specs are used for deep drilling in mining and oil exploration.

- Material Type: Softer materials like soil or clay may not require rigs with high horsepower, while drilling through hard rock would necessitate a more powerful rig.

- Sample Quality: In scientific research or mineral exploration, the quality of the core sample is paramount. Rigs that can extract larger diameter cores are often preferred for these applications.

Applications

- Mining Exploration: In the mining sector, coring rigs are used to drill deep into the earth to discover mineral deposits. The high horsepower and depth capabilities are essential for this field.

- Geotechnical Engineering: Coring rigs in geotechnical engineering are used for various tasks like soil testing and foundation studies. The rigs used here often need to be versatile to handle different soil types and depths.

- Construction: In the construction industry, coring rigs are used for tasks like foundation drilling and installing utility lines. The rigs need to be robust enough to handle the varied materials found on construction sites.

- Environmental Studies: Coring rigs are also used in environmental assessments to collect soil and rock samples. These rigs often require special features to prevent sample contamination.

- Archaeological Exploration: In archaeology, smaller, less powerful rigs are often used to ensure that the historical site is not damaged during the drilling process.

In summary, the coring rig you choose should align closely with the specific needs of your project. Whether you're drilling to find a new mineral deposit, constructing a skyscraper, or conducting an environmental impact study, there's a coring rig designed to meet your needs. Understanding the importance of each specification and how it impacts various applications can help you make an informed decision, ensuring that your drilling operation is both efficient and effective.

Coring Bit Accessories

When it comes to diamond coring, the devil is in the details—or in this case, the accessories. While the coring rig and motor are the backbone and heart of the operation, the accessories are the unsung heroes that can make or break your drilling project. From diamond-impregnated drill bits to core barrels and reaming shells, these accessories play a pivotal role in enhancing the performance and longevity of your coring rigs.

Importance of Different Types of Accessories

- Diamond-Impregnated Drill Bits: These are the workhorses of any coring operation. The industrial diamonds embedded in the bit provide the cutting power to penetrate even the hardest of materials. The quality and type of diamond used can significantly affect the efficiency and speed of your drilling.

- Core Barrels: These cylindrical containers hold the core as it's being extracted. The design and material of the core barrel can impact the quality of the core sample. For example, a double-tube core barrel can help preserve delicate or fractured samples.

- Reaming Shells: These are used to condition the hole and ensure that the core barrel can be easily retrieved. They also help to stabilize the drill string, reducing vibrations and improving the quality of the core sample.

Why Different Accessories Might Be Used

- Material Type: Harder materials like granite or reinforced concrete may require higher-quality diamond bits, while softer materials like soil or clay may not.

- Drilling Depth: Deeper drilling projects may require specialized core barrels designed to handle the pressure and stress at greater depths.

- Project Requirements: Some projects may require undisturbed core samples, necessitating the use of specialized core barrels or reaming shells.

Applications

- Enhancing Drilling Efficiency: High-quality drill bits and reaming shells can significantly speed up the drilling process, saving both time and money.

- Core Sample Extraction: The right core barrel can preserve the integrity of your core sample, providing more accurate data for analysis.

- Drill Bit Replacement: Having a range of drill bits on hand allows for quick replacement, minimizing downtime and keeping your project on schedule.

Specifications

- Material: The most common materials used are industrial diamonds for the drill bits and carbide for the reaming shells.

- Size: The size of these accessories varies based on the core rig and the specific needs of the project. For example, a larger core barrel might be used for projects requiring larger diameter core samples.

In conclusion, while the coring rig and motor may get most of the attention, the accessories are equally vital. They not only enhance the performance and efficiency of your drilling operation but also play a crucial role in the quality of the core samples extracted. Whether you're in mining, construction, or environmental assessment, choosing the right accessories can make a significant difference in the success of your project.

Coring Rig Motors

The motor is often considered the heart of the coring rig. It's the powerhouse that drives the drill bit into the earth, enabling the extraction of valuable core samples for various industrial applications. But not all motors are created equal, and the size of the motor you choose can significantly impact your drilling operation.

Importance of Motor Size

The size of the coring rig motor is crucial for several reasons:

- Power Output: Larger motors generally provide more horsepower, which is essential for drilling through harder materials like granite or reinforced concrete.

- Drilling Depth: The size of the motor affects how deep you can drill. A more powerful motor will allow you to reach greater depths, which is particularly important in mining exploration and geotechnical studies.

- Efficiency: Smaller motors may consume less power, making them more efficient for shallow drilling tasks or for materials that are easier to penetrate.

- Versatility: Some projects may require drilling through a variety of materials, from soft soil to hard rock. A motor with variable speed control can be more versatile, adapting to different drilling conditions.

Why Different Sizes Might Be Used

- Exploratory Drilling: In the early stages of a mining project, you might use a smaller motor for shallow drilling to get a quick sense of the mineral composition of an area.

- Construction: In building projects, larger motors are often used to ensure the structural integrity of foundations, especially in high-rise buildings.

- Environmental Studies: Smaller motors might be used for soil sampling, where the focus is on the upper layers of the earth.

- Oil and Gas: In the petroleum industry, very powerful motors are used to drill deep into the earth to locate oil and gas reserves.

Applications

- Mining Exploration: Powerful motors are essential for drilling deep into the earth to locate valuable mineral deposits. The depth and material hardness often require motors with high horsepower.

- Geotechnical Engineering: In this field, coring rig motors are used for foundation testing and soil sampling. The motors need to be versatile enough to handle a range of materials, from loose soil to hard rock.

- Construction: Whether it's drilling holes for foundation pillars or for installing heavy machinery, construction sites often require coring rig motors that offer a balance of power and precision.

- Archaeological Studies: Smaller motors are often used in archaeological digs where the focus is on preserving the integrity of the site while still obtaining necessary core samples.

- Environmental Assessments: In environmental studies, coring rig motors help in extracting soil and rock samples to assess pollution levels, water quality, and other ecological factors.

Choosing the right motor size for your coring rig is not just a matter of power; it's about aligning the motor's capabilities with the specific needs of your project. From the mining industry to construction and environmental assessments, the motor you choose can make a significant difference in the efficiency and success of your drilling operations.

Conclusion

Diamond coring rigs and their associated motors and accessories are indispensable tools in modern industry. Whether you're in mining, construction, or geotechnical engineering, understanding the capabilities and specifications of these tools is crucial for making informed purchasing decisions. With a rich history and a wide range of applications, diamond coring rigs continue to be at the forefront of subterranean exploration and construction.

Feel free to explore our range of Coring Rigs, Coring Bit Accessories, and Coring Rig Motors to find the perfect fit for your needs.