Electrical Safety Unleashed: The Shocking Truths You Need to Know!

Introduction

Welcome to the electrifying world of professional electrical safety—a realm where knowledge is power and vigilance can mean the difference between life and death. In the dynamic arena of modern industries, professionals encounter electrical hazards daily, from construction sites to manufacturing plants. Understanding the paramount importance of electrical safety isn't just a job requirement; it's a moral imperative. In this comprehensive guide tailored for professionals, we'll navigate through the intricacies of electrical safety, uncovering the critical role it plays in safeguarding both workers and workplaces. Get ready to dive deep into the core principles of electrical safety and emerge equipped with the tools and insights needed to ensure compliance, mitigate risks, and protect lives in the electrified environments of today's industries.

Table of Contents

Part I - Shocking Truths: Why Electrical Safety Is Non-Negotiable!

Part II - Electrical Product Risk, Safety Tips, FAQ and Recommendations

- Electrical Tools

- Electrical Timers & Timer Switches

- Electrical Test Equipment

- Electrical Switches

- Electrical Switch Contact Blocks & Legend Plates

- Electrical Solenoids

- Electrical Receptacles

- Electrical Power Testing

- Electrical Plugs & Connectors

- Electrical Generators

- Electrical Enclosures

- Electrical Enclosure Panels

- Electrical Enclosure Coolers & Blowers

- Electrical Discharge Machines

- Electrical Contact Cleaners & Freeze Sprays

- Electrical Boxes

- Automotive Electrical

Part I - Shocking Truths: Why Electrical Safety Is Non-Negotiable!

Electricity powers our modern world, but it also harbors hidden dangers. From health risks to legal obligations and the importance of staying ahead of outdated products, the importance of electrical safety cannot be overstated. In this eye-opening guide, we'll delve into the shocking truths behind electrical safety, uncovering why it's essential for safeguarding lives, ensuring legal compliance, and staying ahead of potential risks. Let's explore why electrical safety isn't just a recommendation; it's an absolute necessity in today's electrified world.

1. Unveiling Health Risks

Electrical hazards aren't just sparks and wires; they pose grave dangers to health. From minor shocks to life-threatening burns, the consequences of negligence can be dire. Electric shocks disrupt the body's natural signals, leading to muscle contractions, tissue damage, and even cardiac arrest. Furthermore, arc flashes and electrical fires can cause severe burns and respiratory issues. Prioritizing electrical safety isn't just a choice; it's a necessity to safeguard lives and well-being.

2. Legal Wake-Up Call

Ignoring electrical safety isn't just risky; it's illegal. Regulatory bodies establish guidelines and codes to ensure safe electrical practices. Failing to comply with these regulations can lead to fines, penalties, and even lawsuits. Upholding legal obligations isn't just about avoiding trouble; it's about creating a culture of safety that protects employees, customers, and the public.

3. Code Compliance Unveiled

Adherence to electrical codes isn't just about ticking boxes; it's about saving lives. National and international codes set minimum safety standards for electrical design and installation. By following these codes, individuals and organizations can mitigate risks and prevent accidents. Whether it's wiring methods or equipment grounding, code compliance isn't optional; it's a fundamental aspect of electrical safety.

4. Staying Ahead of Outdated Risks

Electrical safety isn't just about the present; it's about preparing for the future. Technological advancements bring safer and more efficient products. Outdated electrical equipment poses increased risks of malfunctions and failures. Regular inspection and maintenance are vital to address these risks. Staying informed and upgrading to newer, safer products isn't just wise; it's essential for maintaining a culture of safety.

In summary, the shocking truths about electrical safety cannot be ignored. From health risks to legal obligations and staying ahead of outdated products, prioritizing safety isn't just a recommendation; it's a non-negotiable imperative. Stay informed, stay compliant, and stay safe!

Part II - Electrical Product Risk, Safety Tips, FAQ and Recommendations

1. Electrical Tools

Overview:

Electrical tools encompass a wide array of equipment used for installation, maintenance, and repair of electrical systems. These include wire cutters, pliers, multimeters, and more.

Top 5 Safety Risks:

- Electric shock due to contact with live wires.

- Arc flash incidents causing burns and explosions.

- Incorrect tool usage leading to short circuits.

- Exposure to hazardous materials like lead in soldering.

- Injury from repetitive motions during prolonged use.

Top 5 Safety Considerations:

- Always use insulated tools to minimize the risk of electric shock.

- Ensure proper training and certification for tool operation.

- Regularly inspect tools for damage and replace worn-out parts.

- Use personal protective equipment (PPE) such as gloves and goggles.

- Follow manufacturer's instructions and safety guidelines meticulously.

Top 10 FAQs:

- Q: Can I use regular pliers for electrical work? A: It's recommended to use insulated pliers specifically designed for electrical tasks.

- Q: How often should I calibrate my multimeter? A: Multimeters should be calibrated annually or as per manufacturer's recommendations.

- Q: Is it safe to work on live circuits? A: It's best to de-energize circuits whenever possible and follow proper lockout/tagout procedures.

- Q: What should I do if a tool gets damaged? A: Immediately remove the tool from service and replace or repair it.

- Q: Are battery-operated tools safer than corded ones? A: Battery-operated tools eliminate the risk of electric shock but require proper battery handling and maintenance.

Product Recommendations:

Electrical Tools - Browse a curated selection of high-quality electrical tools for all your maintenance needs.

-

WilliamsSpecial Price $2861.79 Regular Price $3435.97This product is sold in increments of 1

-

FlukeSpecial Price $288.79 Regular Price $546.99This product is sold in increments of 1

-

Snap-OnSpecial Price $151.49 Regular Price $217.95This product is sold in increments of 1

-

Snap-OnSpecial Price $171.29 Regular Price $248.77This product is sold in increments of 1

-

Snap-OnSpecial Price $772.99 Regular Price $1133.67This product is sold in increments of 1

-

Snap-OnSpecial Price $889.29 Regular Price $1269.41This product is sold in increments of 1

-

Snap-OnSpecial Price $6473.49 Regular Price $9328.24This product is sold in increments of 1

-

Snap-OnSpecial Price $3651.79 Regular Price $5072.29This product is sold in increments of 1

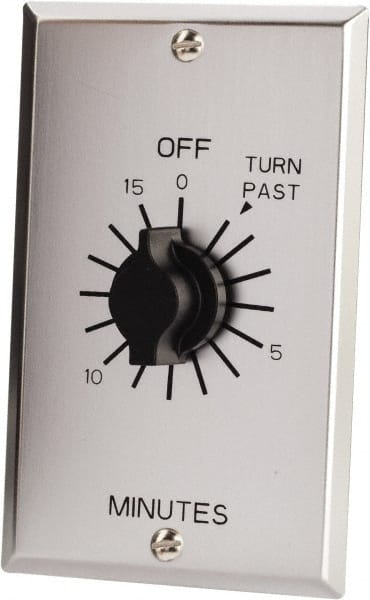

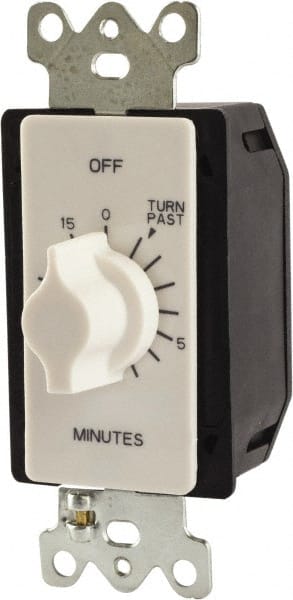

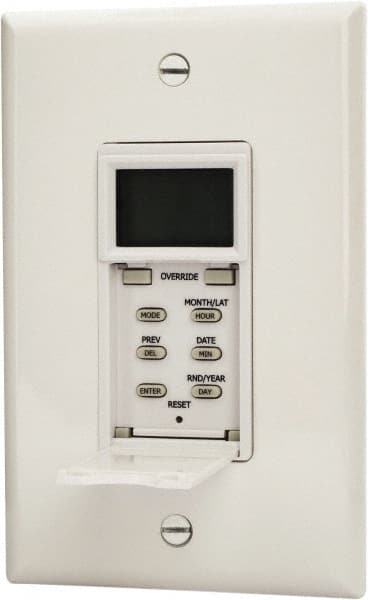

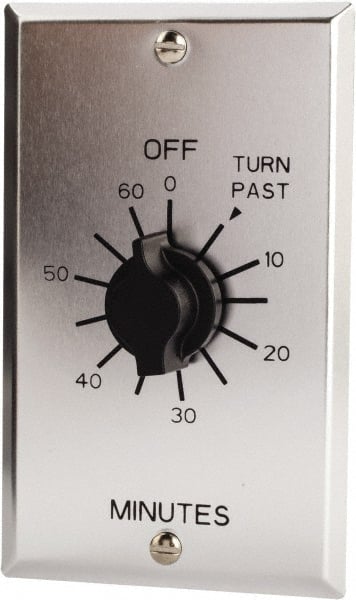

2. Electrical Timers & Timer Switches

Overview:

Electrical timers and timer switches are essential for automating electrical systems, controlling lights, appliances, and machinery based on programmed schedules.

Top 5 Safety Risks:

- Malfunctioning timers leading to unexpected power surges or outages.

- Inadequate grounding causing electrical faults.

- Overloading circuits by connecting too many devices to a single timer.

- Improper installation leading to short circuits or fires.

- Exposure to live electrical components during maintenance.

Top 5 Safety Considerations:

- Select timers with built-in surge protection to safeguard against power fluctuations.

- Ensure proper grounding and wiring according to local electrical codes.

- Perform regular inspections and maintenance to detect and address issues promptly.

- Use caution when handling live wires during installation or maintenance.

- Educate users on proper programming and operation to prevent misuse.

Top 10 FAQs:

- Q: Can I install a timer switch myself? A: Installation should be performed by a qualified electrician to ensure safety and compliance.

- Q: How do I troubleshoot a timer that's not working? A: Check the power source, connections, and programming settings for any errors.

- Q: Can I use a timer with LED or CFL bulbs? A: Yes, but ensure compatibility with the specific type of bulbs to avoid flickering or damage.

- Q: Are digital timers more accurate than mechanical ones? A: Digital timers offer precise scheduling and advanced features compared to mechanical models.

- Q: Can I use a timer for outdoor lighting? A: Yes, choose weatherproof timers designed for outdoor use for optimal performance.

Product Recommendations:

Electrical Timers & Timer Switches - Explore a variety of reliable timers and timer switches to streamline your electrical control systems.

-

TorkSpecial Price $218.79 Regular Price $516.56This product is sold in increments of 1

-

TorkSpecial Price $35.79 Regular Price $66.27This product is sold in increments of 1

-

TorkSpecial Price $35.79 Regular Price $70.85This product is sold in increments of 1

-

TorkSpecial Price $35.79 Regular Price $64.99This product is sold in increments of 1

-

TorkSpecial Price $35.79 Regular Price $69.47This product is sold in increments of 1

-

TorkSpecial Price $66.49 Regular Price $119.19This product is sold in increments of 1

-

TorkSpecial Price $4.49 Regular Price $7.6This product is sold in increments of 1

-

TorkSpecial Price $35.79 Regular Price $64.99This product is sold in increments of 1

3. Electrical Test Equipment

Overview:

Electrical test equipment includes instruments used to measure voltage, current, resistance, and other electrical parameters for troubleshooting, maintenance, and quality assurance purposes.

Top 5 Safety Risks:

- Exposure to high voltage leading to electric shock.

- Accidental short circuits causing equipment damage or injury.

- Inaccurate measurements due to faulty or inadequate test equipment.

- Mishandling of probes or leads resulting in user error.

- Use of damaged or outdated equipment posing safety hazards.

Top 5 Safety Considerations:

- Use only properly calibrated and certified test equipment for accurate measurements.

- Inspect test leads and probes for damage before each use and replace if necessary.

- Verify proper functioning of safety features such as voltage detection and overload protection.

- Follow established safety procedures and protocols when working with live circuits.

- Store test equipment in designated cases or pouches to prevent damage and ensure longevity.

Top 10 FAQs:

- Q: How often should I calibrate my test equipment? A: Test equipment should be calibrated annually or as per manufacturer's recommendations.

- Q: Can I use a multimeter to measure voltage on live circuits? A: Yes, but ensure the multimeter is rated for the voltage level and follow safety precautions.

- Q: What is the difference between analog and digital multimeters? A: Analog multimeters display readings on a scale, while digital multimeters provide numerical values for easier interpretation.

- Q: Can I measure resistance with a digital multimeter? A: Yes, digital multimeters typically offer resistance measurement capabilities.

- Q: How do I test for continuity using a multimeter? A: Set the multimeter to the continuity or resistance mode and touch the probes across the circuit to check for a closed path.

Product Recommendations:

Electrical Test Equipment - Discover a wide range of reliable test equipment to ensure accurate electrical measurements and diagnostics.

-

FlukeSpecial Price $49.79 Regular Price $76.94This product is sold in increments of 1

-

Value CollectionSpecial Price $135.29 Regular Price $212.01This product is sold in increments of 1

-

FlirSpecial Price $111.49 Regular Price $183.53This product is sold in increments of 1

-

Value CollectionSpecial Price $79.79 Regular Price $105.57This product is sold in increments of 1

-

Value CollectionSpecial Price $50.79 Regular Price $71.11This product is sold in increments of 1

-

Value CollectionSpecial Price $39.29 Regular Price $40.74This product is sold in increments of 1

-

Value CollectionSpecial Price $91.99 Regular Price $128.79This product is sold in increments of 1

-

Snap-OnSpecial Price $1233.99 Regular Price $1350This product is sold in increments of 1

4. Electrical Switches

Overview:

Electrical switches are devices used to interrupt or divert the flow of electricity in a circuit, controlling the operation of lights, appliances, and machinery.

Top 5 Safety Risks:

- Electric shock from exposed terminals or faulty wiring.

- Overheating and fire hazards due to loose connections or overload.

- Arcing and sparking leading to equipment damage or injury.

- Switch malfunctions causing unexpected power interruptions or failures.

- Incorrect installation resulting in improper operation or electrical hazards.

Top 5 Safety Considerations:

- Use switches rated for the appropriate voltage and current capacity of the circuit.

- Install switches in accordance with local electrical codes and manufacturer's instructions.

- Regularly inspect switches for signs of wear, damage, or overheating.

- Ensure proper grounding and wiring connections to minimize the risk of arcing.

- Educate users on safe switch operation and emergency procedures in case of malfunction.

Top 10 FAQs:

- Q: Can I replace a light switch myself? A: Yes, but ensure the power is turned off and follow proper installation procedures.

- Q: What is a three-way switch? A: A three-way switch allows control of a single light from two different locations.

- Q: How do I troubleshoot a switch that's not working? A: Check for loose connections, damaged wiring, or faulty switches, and replace if necessary.

- Q: Can I install a dimmer switch with any type of light fixture? A: Dimmer switches are compatible with most incandescent, LED, and CFL light fixtures.

- Q: What is the lifespan of a typical switch? A: Switches can last for many years with proper maintenance and usage.

Product Recommendations:

Electrical Switches - Explore a variety of high-quality electrical switches for residential, commercial, and industrial applications.

-

SchneiderSpecial Price $75.49 Regular Price $105.69This product is sold in increments of 1

-

LevitonSpecial Price $2.79 Regular Price $5.03This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $697.99 Regular Price $1321.99This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $290.49 Regular Price $550.29This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $304.99 Regular Price $577.79This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $498.29 Regular Price $943.79This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $461.49 Regular Price $874.29This product is sold in increments of 1

-

Idem Safety Switches USASpecial Price $516.49 Regular Price $978.29This product is sold in increments of 1

5. Electrical Switch Contact Blocks & Legend Plates

Overview:

Electrical switch contact blocks and legend plates are components used in conjunction with switches to indicate their function and status, enhancing control and visibility in electrical systems.

Top 5 Safety Risks:

- Misidentification of switch functions leading to improper operation.

- Damage to legend plates causing confusion or loss of functionality.

- Loose or faulty contact blocks resulting in intermittent operation or failure.

- Exposure to live electrical components during maintenance or replacement.

- Inadequate labeling or marking contributing to operational errors or accidents.

Top 5 Safety Considerations:

- Ensure clear and accurate labeling of legend plates to prevent confusion or ambiguity.

- Use durable materials resistant to wear, fading, and tampering for legend plates.

- Regularly inspect contact blocks for proper alignment, tightness, and functionality.

- De-energize circuits and follow lockout/tagout procedures before servicing or replacing contact blocks.

- Provide adequate training and documentation for users regarding switch functions and labeling conventions.

Top 10 FAQs:

- Q: Can I customize legend plates for specific applications? A: Yes, many manufacturers offer custom labeling options to suit unique requirements.

- Q: What is the purpose of a contact block in a switch? A: Contact blocks provide electrical continuity and signal input/output for switch operation.

- Q: Are legend plates necessary for all switches? A: Legend plates enhance visibility and clarity, especially in complex control systems.

- Q: How do I replace a damaged legend plate? A: Remove the old legend plate and secure the new one in its place using appropriate mounting hardware.

- Q: Can I retrofit legend plates onto existing switches? A: Yes, select legend plates designed to fit common switch models for easy installation.

Product Recommendations:

Electrical Switch Contact Blocks & Legend Plates - Choose from a wide selection of contact blocks and legend plates to enhance the functionality and safety of your electrical switches.

-

Hubbell WiringSpecial Price $24.29 Regular Price $26.66This product is sold in increments of 1

-

Hubbell WiringSpecial Price $68.79 Regular Price $106.56This product is sold in increments of 1

-

Hubbell WiringSpecial Price $7.29 Regular Price $19.33This product is sold in increments of 1

-

Hubbell WiringSpecial Price $19.99 Regular Price $26.66This product is sold in increments of 1

-

Hubbell WiringSpecial Price $17.99 Regular Price $26.66This product is sold in increments of 1

-

Hubbell WiringSpecial Price $71.49 Regular Price $100.09This product is sold in increments of 1

-

Hubbell WiringSpecial Price $7.29 Regular Price $19.33This product is sold in increments of 1

-

Hubbell WiringSpecial Price $17.99 Regular Price $19.33This product is sold in increments of 1

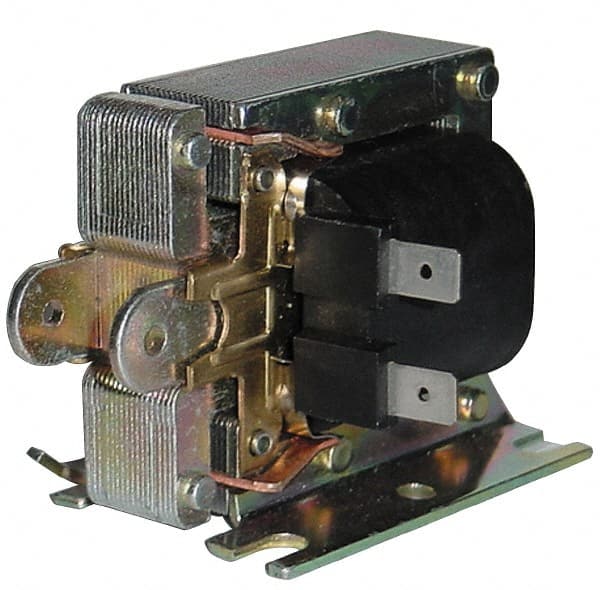

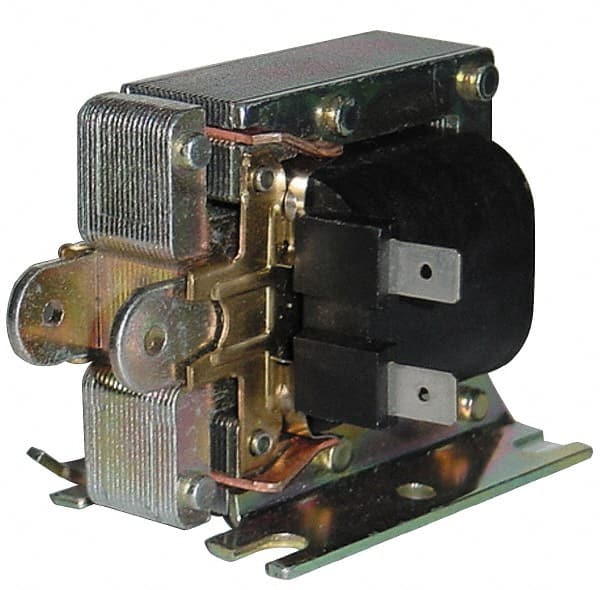

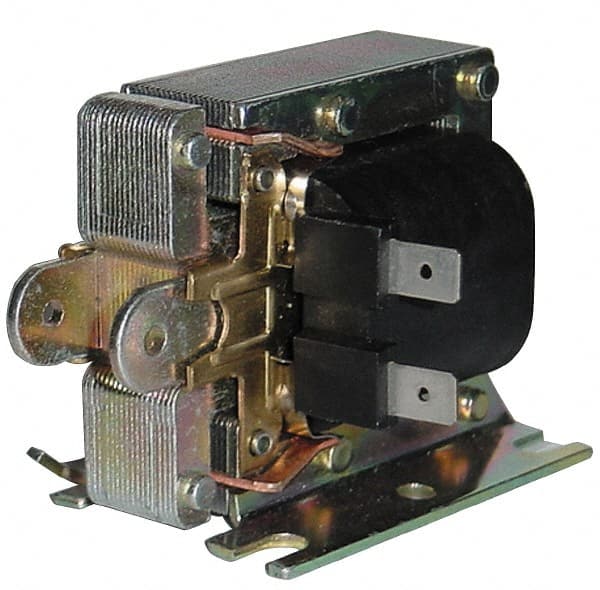

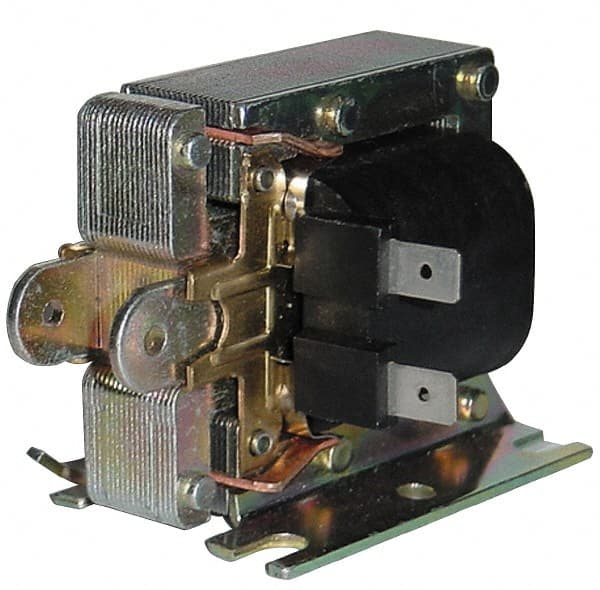

6. Electrical Solenoids

Overview:

Electrical solenoids are electromechanical devices used to control the movement of mechanical components by converting electrical energy into linear motion.

Top 5 Safety Risks:

- Overheating due to prolonged operation or inadequate ventilation.

- Coil burnout or short circuits causing solenoid failure.

- Mechanical jamming or binding leading to malfunction or damage.

- Incorrect wiring resulting in erratic or unintended movement.

- Exposure to high magnetic fields posing health risks or interference with nearby equipment.

Top 5 Safety Considerations:

- Select solenoids rated for the specific voltage, current, and duty cycle of the application.

- Install solenoids in well-ventilated areas to dissipate heat and prevent overheating.

- Regularly inspect solenoid coils for signs of wear, damage, or corrosion.

- Use proper wiring techniques and connectors to ensure secure and reliable connections.

- Implement fail-safe mechanisms or redundant controls to mitigate risks of unintended operation.

Top 10 FAQs:

- Q: Can I use a solenoid for continuous duty applications? A: Choose solenoids with continuous duty ratings for prolonged operation.

- Q: How do I determine the correct voltage for a solenoid? A: Refer to the manufacturer's specifications and application requirements for voltage compatibility.

- Q: What is the difference between AC and DC solenoids? A: AC solenoids operate on alternating current, while DC solenoids operate on direct current.

- Q: Can I adjust the stroke length of a solenoid? A: Some solenoids offer adjustable stroke lengths or optional stroke limiters for customization.

- Q: Are solenoids affected by magnetic interference from nearby equipment? A: Shielding or distance separation may be necessary to minimize interference effects.

Product Recommendations:

Electrical Solenoids - Explore a diverse range of high-performance solenoids for precise control and automation applications.

-

Value CollectionSpecial Price $71.79 Regular Price $120.56This product is sold in increments of 1

-

GenericSpecial Price $26.49 Regular Price $29.27This product is sold in increments of 1

-

Value CollectionSpecial Price $71.49 Regular Price $92.12This product is sold in increments of 1

-

Value CollectionSpecial Price $72.99 Regular Price $90.74This product is sold in increments of 1

-

GuardianSpecial Price $114.49 Regular Price $125.38This product is sold in increments of 1

-

GuardianSpecial Price $90.29 Regular Price $111.43This product is sold in increments of 1

-

GuardianSpecial Price $90.29 Regular Price $113.41This product is sold in increments of 1

-

GuardianSpecial Price $90.29 Regular Price $111.37This product is sold in increments of 1

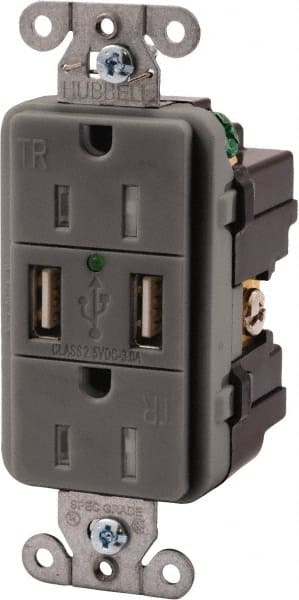

7. Electrical Receptacles

Overview:

Electrical receptacles, commonly known as outlets, are devices used to connect electrical devices to power sources, providing a safe and convenient means of access to electricity.

Top 5 Safety Risks:

- Electric shock from exposed contacts or damaged wiring.

- Overloading circuits by connecting multiple devices to a single receptacle.

- Loose or damaged receptacles causing intermittent power supply or fire hazards.

- Inadequate grounding leading to electrical faults or equipment damage.

- Tampering or misuse resulting in operational errors or accidents.

Top 5 Safety Considerations:

- Install tamper-resistant receptacles to prevent accidental insertion of foreign objects.

- Use ground-fault circuit interrupters (GFCIs) in areas prone to moisture or electrical hazards.

- Regularly inspect receptacles for signs of damage, wear, or overheating.

- Avoid overloading circuits by distributing electrical loads evenly among multiple receptacles.

- Educate users on proper receptacle usage and the importance of electrical safety.

Top 10 FAQs:

- Q: How many devices can I plug into a single receptacle? A: It's best to follow the manufacturer's recommendations and local electrical codes regarding outlet capacity.

- Q: What is the difference between a standard outlet and a GFCI outlet? A: GFCI outlets monitor electrical currents and trip the circuit if they detect a ground fault, providing enhanced protection against electric shock.

- Q: Can I replace a standard outlet with a GFCI outlet? A: Yes, but consult a qualified electrician to ensure proper installation and compliance with electrical codes.

- Q: Are tamper-resistant receptacles required by code? A: In many jurisdictions, tamper-resistant receptacles are mandated for new construction and renovations to enhance child safety.

- Q: How do I reset a tripped GFCI outlet? A: Press the reset button on the GFCI outlet to restore power after addressing the underlying issue.

Product Recommendations:

Electrical Receptacles - Explore a wide selection of high-quality electrical receptacles designed for safety, durability, and reliability.

-

Pro-SourceSpecial Price $226.29 Regular Price $229.94This product is sold in increments of 1

-

HUbbell WiringSpecial Price $18.99 Regular Price $29.28This product is sold in increments of 1

-

SchneiderSpecial Price $30.29 Regular Price $45.47This product is sold in increments of 1

-

Hubbell WiringSpecial Price $90.49 Regular Price $138.14This product is sold in increments of 1

-

HUbbell WiringSpecial Price $45.49 Regular Price $60.72This product is sold in increments of 1

-

HUbbell WiringSpecial Price $47.29 Regular Price $62.32This product is sold in increments of 1

-

Hubbell WiringSpecial Price $57.49 Regular Price $87.41This product is sold in increments of 1

-

Hubbell WiringSpecial Price $39.29 Regular Price $104.02This product is sold in increments of 1

8. Electrical Power Testing

Overview:

Electrical power testing involves the evaluation of electrical systems and components to ensure proper functionality, performance, and compliance with safety standards.

Top 5 Safety Risks:

- Exposure to high voltage leading to electric shock or arc flash incidents.

- Incorrect test setup or connections resulting in inaccurate readings.

- Use of damaged or malfunctioning testing equipment posing safety hazards.

- Failure to de-energize circuits before testing leading to accidents or equipment damage.

- Inadequate training or supervision contributing to procedural errors or mishaps.

Top 5 Safety Considerations:

- Use appropriate personal protective equipment (PPE) such as insulated gloves and goggles when working with live circuits.

- Verify the integrity and calibration of testing equipment before each use.

- Follow established safety procedures and protocols for testing energized circuits.

- Implement lockout/tagout (LOTO) procedures to isolate and de-energize circuits prior to testing.

- Provide comprehensive training and certification for personnel involved in electrical testing activities.

Top 10 FAQs:

- Q: What types of tests are performed during electrical power testing? A: Common tests include voltage measurement, continuity testing, insulation resistance testing, and load analysis.

- Q: Can I perform power testing on live circuits? A: Power testing on live circuits should be conducted by qualified personnel using proper safety precautions and equipment.

- Q: How do I interpret test results from electrical power testing? A: Refer to equipment manuals, standards, and guidelines for interpretation of test data and recommended corrective actions.

- Q: What is insulation resistance testing, and why is it important? A: Insulation resistance testing assesses the integrity of insulation materials to prevent electrical leakage and ensure safety and reliability.

- Q: Are there portable testing solutions for field applications? A: Yes, many testing instruments are designed for portable use in field environments, offering convenience and versatility.

Product Recommendations:

Electrical Power Testing - Explore a comprehensive range of electrical testing instruments for accurate and reliable power analysis and diagnostics.

-

Triplett Test EquipmentSpecial Price $144.79 Regular Price $274.29This product is sold in increments of 1

-

Integrated Supply NetworkSpecial Price $583.99 Regular Price $1106.29This product is sold in increments of 1

-

REED InstrumentsSpecial Price $152.29 Regular Price $238.43This product is sold in increments of 1

-

REED InstrumentsSpecial Price $294.29 Regular Price $463.14This product is sold in increments of 1

-

Tower ManufacturingSpecial Price $59.99 Regular Price $113.79This product is sold in increments of 1

-

Tower ManufacturingSpecial Price $34.49 Regular Price $65.49This product is sold in increments of 1

-

Triplett Test EquipmentSpecial Price $428.49 Regular Price $811.79This product is sold in increments of 1

-

FLIRSpecial Price $2764.29 Regular Price $5235.49This product is sold in increments of 1

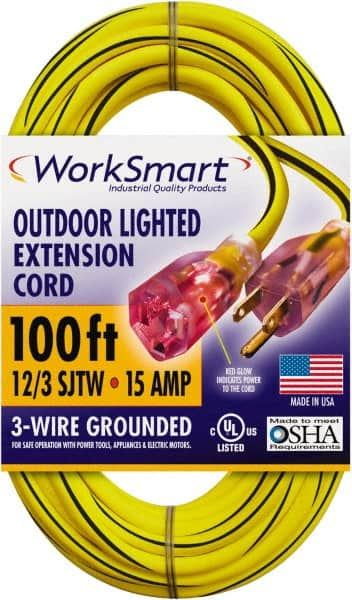

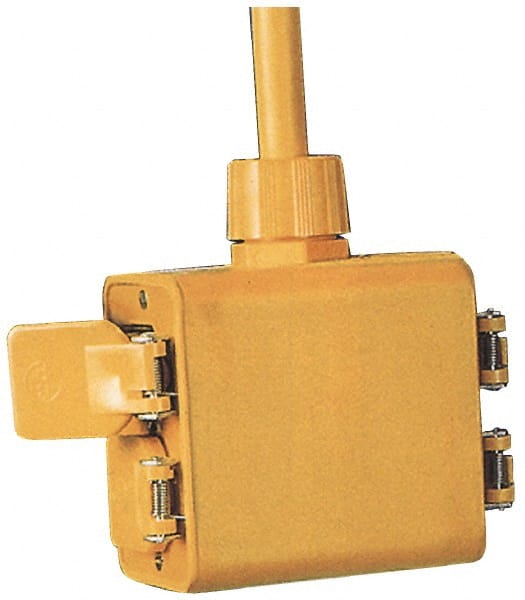

9. Electrical Plugs & Connectors

Overview:

Electrical plugs and connectors are essential components for connecting electrical devices and equipment to power sources, ensuring safe and reliable electrical connections.

Top 5 Safety Risks:

- Electric shock from exposed contacts or damaged wiring.

- Overloading circuits by connecting devices with incompatible power ratings.

- Loose or improper connections leading to heat buildup or equipment damage.

- Inadequate strain relief causing cables to fray or disconnect.

- Exposure to moisture or environmental contaminants compromising electrical integrity.

Top 5 Safety Considerations:

- Choose plugs and connectors rated for the specific voltage, current, and environmental conditions of the application.

- Inspect plugs and connectors for damage, wear, or corrosion before each use.

- Ensure proper strain relief and cable management to prevent cable damage and disconnection.

- Use locking or twist-locking connectors for secure and reliable connections in high-vibration environments.

- Implement periodic maintenance and testing of plugs and connectors to detect and address issues proactively.

Top 10 FAQs:

- Q: Can I use a 220V plug in a 110V outlet? A: No, using incompatible plugs and outlets can lead to electrical hazards and equipment damage.

- Q: What is the difference between straight-blade and twist-lock plugs? A: Twist-lock plugs provide a secure and reliable connection by twisting and locking into place, ideal for high-vibration environments.

- Q: How do I wire a plug or connector? A: Follow manufacturer's instructions and wiring diagrams carefully to ensure correct wiring and connections.

- Q: Are weatherproof plugs necessary for outdoor use? A: Yes, weatherproof plugs and connectors are designed to withstand exposure to moisture and environmental elements.

- Q: Can I repair a damaged plug or connector? A: It's recommended to replace damaged plugs or connectors to maintain electrical safety and reliability.

Product Recommendations:

Electrical Plugs & Connectors - Discover a wide selection of durable plugs and connectors for residential, commercial, and industrial applications.

-

HUbbell WiringSpecial Price $18.99 Regular Price $29.28This product is sold in increments of 1

-

CooperSpecial Price $79.29 Regular Price $111.01This product is sold in increments of 1

-

CooperSpecial Price $70.99 Regular Price $99.39This product is sold in increments of 1

-

Accuform ManufacturingSpecial Price $41.29 Regular Price $78.29This product is sold in increments of 1

-

Tower ManufacturingSpecial Price $59.99 Regular Price $113.79This product is sold in increments of 1

-

CooperSpecial Price $175.79 Regular Price $314.63This product is sold in increments of 1

-

CooperSpecial Price $188.29 Regular Price $335.3This product is sold in increments of 1

-

CooperSpecial Price $146.79 Regular Price $262.21This product is sold in increments of 1

10. Electrical Generators

Overview:

Electrical generators are devices that convert mechanical energy into electrical energy, providing backup power during outages or serving as primary power sources in remote locations.

Top 5 Safety Risks:

- Carbon monoxide poisoning from generator exhaust fumes in enclosed or poorly ventilated spaces.

- Electric shock from improper grounding or inadequate electrical protection.

- Overloading generators by connecting too many devices or appliances.

- Fuel leaks or spills leading to fire hazards or environmental contamination.

- Improper storage or maintenance resulting in equipment malfunction or failure.

Top 5 Safety Considerations:

- Install generators outdoors in well-ventilated areas away from doors, windows, and vents.

- Use carbon monoxide detectors and ensure proper exhaust system installation to prevent buildup of toxic gases.

- Implement proper grounding and electrical protection measures to prevent electric shock hazards.

- Calculate and distribute electrical loads evenly to avoid overloading generators.

- Follow manufacturer's recommendations and maintenance schedules for fueling, servicing, and storing generators.

Top 10 FAQs:

- Q: What size generator do I need for my home or business? A: Generator size depends on factors such as power requirements, fuel type, and intended use. Consult a qualified electrician for proper sizing.

- Q: Can I connect a generator directly to my home's electrical panel? A: Yes, but it requires proper installation of a transfer switch by a licensed electrician to ensure safety and compliance.

- Q: How often should I test my generator? A: Test generators regularly, typically monthly, to verify proper operation and readiness for emergencies.

- Q: What fuel types are commonly used in generators? A: Gasoline, diesel, propane, and natural gas are common fuel options for generators, each with its advantages and limitations.

- Q: Can I use a portable generator indoors? A: Portable generators should only be used outdoors in well-ventilated areas to prevent carbon monoxide poisoning and fire hazards.

Product Recommendations:

Electrical Generators - Explore a diverse selection of reliable generators for residential, commercial, and industrial applications, including portable and standby models.

-

WincoSpecial Price $81.49 Regular Price $160.6This product is sold in increments of 1

-

WincoSpecial Price $334.29 Regular Price $596.23This product is sold in increments of 1

-

WincoSpecial Price $111.29 Regular Price $198.74This product is sold in increments of 1

-

WincoSpecial Price $490.99 Regular Price $841.33This product is sold in increments of 1

-

WincoSpecial Price $443.99 Regular Price $700.53This product is sold in increments of 1

-

WincoSpecial Price $846.49 Regular Price $1282.09This product is sold in increments of 1

-

WincoSpecial Price $1086.99 Regular Price $1722.98This product is sold in increments of 1

-

WincoSpecial Price $366.49 Regular Price $747.66This product is sold in increments of 1

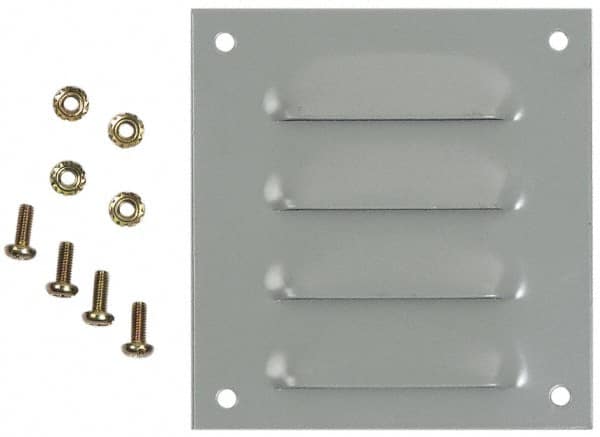

11. Electrical Enclosures

Overview:

Electrical enclosures are protective housings used to contain and shield electrical components, equipment, and wiring from environmental factors, dust, moisture, and physical damage.

Top 5 Safety Risks:

- Inadequate ventilation causing heat buildup and overheating of enclosed components.

- Exposure to moisture leading to corrosion, short circuits, or electrical faults.

- Improper installation or grounding resulting in electrical hazards or equipment malfunction.

- Insufficient space or access for maintenance and inspection of enclosed equipment.

- Use of incompatible or non-compliant enclosures for specific applications or environments.

Top 5 Safety Considerations:

- Select enclosures rated for the environmental conditions, including temperature, humidity, and corrosive agents.

- Ensure proper ventilation and cooling to maintain optimal operating temperatures within enclosures.

- Use watertight or waterproof enclosures for outdoor or wet environments to prevent moisture ingress.

- Implement proper grounding and bonding of enclosures to minimize the risk of electrical faults and shocks.

- Allow sufficient space and access for equipment installation, maintenance, and inspection within enclosures.

Top 10 FAQs:

- Q: What materials are commonly used for electrical enclosures? A: Steel, aluminum, stainless steel, and fiberglass are common materials for electrical enclosures, each offering unique benefits and applications.

- Q: Can I modify or drill holes in an electrical enclosure? A: Yes, but modifications should be performed carefully to maintain the integrity and protective properties of the enclosure.

- Q: How do I determine the appropriate size of an electrical enclosure? A: Consider the size and number of components to be housed, as well as future expansion needs, when selecting enclosure dimensions.

- Q: Are there specific requirements for ventilation in electrical enclosures? A: Ventilation requirements depend on factors such as heat dissipation, environmental conditions, and equipment specifications. Consult applicable standards and guidelines for recommendations.

- Q: Can I use an outdoor-rated enclosure indoors? A: Yes, outdoor-rated enclosures can be used indoors, but indoor-rated enclosures may not provide adequate protection against outdoor elements.

Product Recommendations:

Electrical Enclosures - Explore a diverse range of high-quality electrical enclosures designed to protect and safeguard sensitive equipment and components in various applications and environments.

-

WiegmannSpecial Price $43.29 Regular Price $57.77This product is sold in increments of 1

-

WiegmannSpecial Price $59.29 Regular Price $79.2This product is sold in increments of 1

-

HubbellSpecial Price $1059.99 Regular Price $1286.43This product is sold in increments of 1

-

PentairSpecial Price $1567.79 Regular Price $2969.49This product is sold in increments of 1

-

CooperSpecial Price $109.79 Regular Price $140.99This product is sold in increments of 1

-

HubbellSpecial Price $196.29 Regular Price $244.84This product is sold in increments of 1

-

CooperSpecial Price $32.79 Regular Price $48.12This product is sold in increments of 1

-

WiegmannSpecial Price $31.29 Regular Price $49.87This product is sold in increments of 1

12. Electrical Enclosure Panels

Overview:

Electrical enclosure panels are integral components of electrical enclosures, providing mounting surfaces for equipment, controls, and accessories, while also enhancing accessibility and organization within enclosures.

Top 5 Safety Risks:

- Inadequate support or mounting of heavy or bulky equipment on enclosure panels leading to structural failure or hazards.

- Improper labeling or identification of panel-mounted components causing confusion or operational errors.

- Overcrowding of panels with excessive equipment or wiring, hindering access and maintenance.

- Insufficient clearance or spacing between panel-mounted components increasing the risk of heat buildup or electrical interference.

- Use of incompatible or non-compliant panel materials or finishes for specific applications or environments.

Top 5 Safety Considerations:

- Ensure proper mounting and support of equipment on enclosure panels to prevent instability or collapse.

- Clearly label and identify panel-mounted components for easy identification and troubleshooting.

- Plan and organize panel layouts to optimize space utilization and facilitate access for maintenance and inspection.

- Allow adequate clearance and spacing between components to promote airflow and prevent overheating.

- Select panel materials and finishes that are durable, corrosion-resistant, and compliant with environmental requirements.

Top 10 FAQs:

- Q: What types of equipment can be mounted on electrical enclosure panels? A: Equipment such as circuit breakers, switches, relays, meters, and control devices can be mounted on enclosure panels depending on application requirements.

- Q: Can I add or remove equipment from an enclosure panel? A: Yes, but modifications should be performed in accordance with manufacturer's instructions and applicable safety standards.

- Q: How do I access components mounted on an enclosure panel? A: Enclosure doors or covers can be opened to access panel-mounted components for maintenance, inspection, or servicing.

- Q: Are there specific requirements for panel labeling and identification? A: Yes, labeling requirements may vary depending on industry standards, regulatory codes, and application specifications.

- Q: Can I customize enclosure panels for specific applications? A: Yes, many manufacturers offer custom panel fabrication services to meet unique requirements and specifications.

Product Recommendations:

Electrical Enclosure Panels - Explore a wide selection of high-quality enclosure panels designed to accommodate various equipment and components while ensuring safety, reliability, and ease of maintenance.

-

HubbellSpecial Price $166.79 Regular Price $238.21This product is sold in increments of 1

-

HubbellSpecial Price $191.49 Regular Price $274.04This product is sold in increments of 1

-

PentairSpecial Price $196.79 Regular Price $372.79This product is sold in increments of 1

-

PentairSpecial Price $148.29 Regular Price $280.99This product is sold in increments of 1

-

HubbellSpecial Price $745.99 Regular Price $988.63This product is sold in increments of 1

-

HubbellSpecial Price $715.49 Regular Price $1073.36This product is sold in increments of 1

-

HubbellSpecial Price $233.99 Regular Price $334.95This product is sold in increments of 1

-

HubbellSpecial Price $575.29 Regular Price $826.98This product is sold in increments of 1

13. Electrical Enclosure Coolers & Blowers

Overview:

Electrical enclosure coolers and blowers are specialized cooling systems designed to regulate temperature and dissipate heat within electrical enclosures, ensuring optimal performance and reliability of enclosed components.

Top 5 Safety Risks:

- Overheating of enclosed components due to inadequate cooling or ventilation.

- Inefficient heat dissipation leading to premature failure or degradation of electronic equipment.

- Exposure to dust, debris, or contaminants compromising cooling system efficiency and effectiveness.

- Improper installation or maintenance of coolers and blowers resulting in operational issues or safety hazards.

- Use of incompatible or undersized cooling solutions for specific enclosure sizes or thermal loads.

Top 5 Safety Considerations:

- Choose cooling solutions rated for the thermal requirements and environmental conditions of the electrical enclosure.

- Regularly inspect and clean coolers and blowers to remove dust, debris, and obstructions hindering airflow.

- Ensure proper installation and mounting of cooling systems to maximize heat transfer and airflow within enclosures.

- Implement redundancy or backup cooling solutions to mitigate risks of equipment overheating or failure.

- Monitor enclosure temperatures and cooling system performance to detect and address issues proactively.

Top 10 FAQs:

- Q: What types of cooling systems are available for electrical enclosures? A: Cooling systems such as air conditioners, fans, heat exchangers, and thermoelectric coolers are commonly used to regulate temperature within enclosures.

- Q: How do I determine the appropriate cooling capacity for my enclosure? A: Consider factors such as enclosure size, thermal load, ambient temperature, and desired temperature range when selecting cooling solutions.

- Q: Can I install multiple cooling systems in the same enclosure? A: Yes, multiple cooling systems can be installed to provide redundancy or increase cooling capacity as needed.

- Q: Are there energy-efficient cooling options available for electrical enclosures? A: Yes, energy-efficient cooling solutions such as variable-speed fans and thermoelectric coolers are available to minimize power consumption and operating costs.

- Q: How do I troubleshoot cooling system issues in an electrical enclosure? A: Check for obstructions, verify power supply, and inspect cooling system components for signs of damage or malfunction.

Product Recommendations:

Electrical Enclosure Coolers & Blowers - Explore a range of efficient and reliable cooling solutions designed to maintain optimal operating temperatures within electrical enclosures, ensuring equipment performance and longevity.

-

ExairSpecial Price $739.49 Regular Price $1035.29This product is sold in increments of 1

-

SchneiderSpecial Price $172.49 Regular Price $639.32This product is sold in increments of 1

-

SchneiderSpecial Price $1026.99 Regular Price $1437.79This product is sold in increments of 1

-

WiegmannSpecial Price $1672.49 Regular Price $2341.49This product is sold in increments of 1

-

CooperSpecial Price $750.29 Regular Price $1278.69This product is sold in increments of 1

-

CooperSpecial Price $538.29 Regular Price $991.85This product is sold in increments of 1

-

Nvent HoffmanSpecial Price $802.99 Regular Price $1206.35This product is sold in increments of 1

-

Nvent HoffmanSpecial Price $569.99 Regular Price $696.68This product is sold in increments of 1

14. Electrical Discharge Machines

Overview:

Electrical discharge machines (EDM) are precision machining tools that use electrical discharges to shape, drill, or cut conductive materials with high accuracy and repeatability.

Top 5 Safety Risks:

- Electric shock hazards from high-voltage power supplies and exposed electrical components.

- Fire hazards due to combustible materials, sparks, or electrical arcing during machining operations.

- Exposure to hazardous fumes, gases, or particulates generated by EDM processes.

- Operator injuries from moving machine components, sharp tools, or ejected workpieces.

- Inadequate ventilation or containment of machining debris, leading to environmental contamination or health risks.

Top 5 Safety Considerations:

- Provide comprehensive training and certification for operators on safe operation and maintenance of EDM equipment.

- Implement proper machine guarding and interlocks to prevent access to hazardous areas during operation.

- Use appropriate personal protective equipment (PPE) such as safety glasses, gloves, and respiratory protection.

- Establish and enforce safety protocols for handling and disposal of machining waste, fluids, and byproducts.

- Conduct regular inspections and maintenance of EDM equipment to detect and address potential safety hazards or malfunctions.

Top 10 FAQs:

- Q: What types of materials can be machined with electrical discharge machines? A: EDM processes are suitable for machining conductive materials such as metals, alloys, and ceramics.

- Q: How does electrical discharge machining work? A: EDM uses electrical discharges to remove material from workpieces through controlled erosion or vaporization.

- Q: What are the advantages of electrical discharge machining over conventional machining methods? A: EDM offers high precision, fine surface finishes, and the ability to machine complex shapes or hardened materials.

- Q: Are there different types of electrical discharge machines? A: Yes, common types include wire EDM, sinker EDM, and EDM drilling machines, each suited for specific applications and materials.

- Q: How do I maintain EDM equipment for optimal performance and safety? A: Follow manufacturer's recommendations for regular maintenance, lubrication, and inspection of EDM components and systems.

Product Recommendations:

Electrical Discharge Machines - Explore a range of advanced electrical discharge machines designed for precision machining applications, offering high performance, accuracy, and reliability.

15. Electrical Contact Cleaners & Freeze Sprays

Overview:

Electrical contact cleaners and freeze sprays are specialized chemicals used to clean, degrease, and maintain electrical contacts, connectors, and components, ensuring optimal conductivity and reliability.

Top 5 Safety Risks:

- Exposure to hazardous chemicals or solvents causing skin irritation, respiratory issues, or other health hazards.

- Fire hazards from flammable or combustible cleaning agents, especially in high-temperature or confined spaces.

- Inhalation of vapors or aerosols from spray applications leading to respiratory irritation or toxicity.

- Contact with energized electrical components or circuits while cleaning, posing risks of electric shock or injury.

- Improper storage, handling, or disposal of cleaning chemicals resulting in environmental contamination or regulatory violations.

Top 5 Safety Considerations:

- Use cleaning products with non-toxic, non-flammable, and environmentally friendly formulations whenever possible.

- Ensure adequate ventilation in work areas to minimize exposure to chemical vapors or aerosols.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators when handling cleaning chemicals.

- Follow manufacturer's instructions and safety data sheets (SDS) for proper use, storage, and disposal of cleaning products.

- Implement lockout/tagout (LOTO) procedures and de-energize electrical equipment before cleaning to prevent accidental contact or electrical hazards.

Top 10 FAQs:

- Q: What types of contaminants can be removed with electrical contact cleaners? A: Electrical contact cleaners can remove dust, dirt, grease, oil, oxidation, and other residues from electrical contacts and components.

- Q: Can I use contact cleaners on energized equipment? A: It's recommended to de-energize equipment and follow proper safety procedures before applying contact cleaners to avoid electrical hazards.

- Q: Are contact cleaners safe for use on sensitive electronic components? A: Some contact cleaners are formulated to be safe for use on electronic components, but it's important to verify compatibility and test on a small area first.

- Q: How do I choose the right contact cleaner for my application? A: Consider factors such as compatibility with materials, environmental conditions, and cleaning requirements when selecting contact cleaners.

- Q: Are there alternatives to aerosol spray cleaners? A: Yes, contact cleaners are available in various formulations including wipes, pens, brushes, and bulk liquids for different application methods and preferences.

Product Recommendations:

Electrical Contact Cleaners & Freeze Sprays - Explore a selection of high-quality electrical contact cleaners and freeze sprays designed to effectively clean and maintain electrical contacts and components, ensuring optimal performance and reliability.

-

CRCSpecial Price $21.29 Regular Price $32.95This product is sold in increments of 1

-

KrugerSpecial Price $23.49 Regular Price $44.49This product is sold in increments of 1

-

LpsSpecial Price $6.99 Regular Price $8.03This product is sold in increments of 1

-

OsbornSpecial Price $26.29 Regular Price $34.55This product is sold in increments of 1

-

KrugerSpecial Price $17.49 Regular Price $33.29This product is sold in increments of 1

-

LpsSpecial Price $158.79 Regular Price $222.31This product is sold in increments of 1

-

LPSSpecial Price $35.29 Regular Price $54.6This product is sold in increments of 1

-

Rochester MidlandSpecial Price $440.29 Regular Price $472.84This product is sold in increments of 1

16. Electrical Boxes

Overview:

Electrical boxes, also known as junction boxes or outlet boxes, are enclosures used to house electrical wiring connections, switches, outlets, and other devices, providing protection and organization for electrical installations.

Top 5 Safety Risks:

- Overcrowding of boxes with excessive wiring or devices leading to overheating, wire damage, or electrical faults.

- Improper installation or mounting of boxes resulting in instability, insufficient support, or structural hazards.

- Inadequate sealing or protection of boxes from moisture, dust, or environmental contaminants compromising electrical integrity.

- Use of non-compliant or incompatible boxes for specific applications, voltages, or environmental conditions.

- Insufficient clearance or access around boxes hindering maintenance, inspection, or troubleshooting.

Top 5 Safety Considerations:

- Select electrical boxes rated for the intended application, environment, and electrical code requirements.

- Ensure proper sizing and spacing of boxes to accommodate wiring, devices, and future expansions.

- Use gaskets, seals, or weatherproofing materials to protect boxes from moisture, dust, and debris ingress.

- Install boxes securely and according to manufacturer's instructions, ensuring proper support and alignment.

- Provide adequate access and clearance around boxes for maintenance, inspection, and servicing activities.

Top 10 FAQs:

- Q: What materials are electrical boxes typically made of? A: Electrical boxes are commonly made of metal (steel or aluminum), plastic (PVC or ABS), or fiberglass, each offering unique properties and suitability for different applications.

- Q: Can I install multiple circuits in the same electrical box? A: Yes, but ensure proper sizing, separation, and labeling of circuits to comply with electrical code requirements and prevent overloading.

- Q: What is the difference between a junction box and an outlet box? A: Junction boxes are used for wire connections and splices, while outlet boxes are designed to mount electrical outlets, switches, or devices.

- Q: Do electrical boxes require sealing or waterproofing? A: Boxes installed in wet or outdoor environments may require sealing or waterproofing measures to prevent moisture ingress and maintain electrical safety.

- Q: Can I paint electrical boxes to match wall or ceiling finishes? A: Yes, but use non-conductive paint and avoid painting over openings, knockouts, or labeling on boxes.

Product Recommendations:

Electrical Boxes - Explore a variety of electrical boxes designed to meet diverse installation requirements, offering durability, compatibility, and compliance with electrical codes and standards.

-

HUbbell WiringSpecial Price $18.99 Regular Price $29.28This product is sold in increments of 1

-

Hubbell ElectricalSpecial Price $2.79 Regular Price $5.29This product is sold in increments of 1

-

Hubbell-RacoSpecial Price $6.29 Regular Price $11.23This product is sold in increments of 1

-

Hubbell-RacoSpecial Price $5.79 Regular Price $13.42This product is sold in increments of 1

-

WoodheadSpecial Price $790.99 Regular Price $1107.39This product is sold in increments of 1

-

CooperSpecial Price $97.79 Regular Price $162.39This product is sold in increments of 1

-

WoodheadSpecial Price $911.49 Regular Price $1276.09This product is sold in increments of 1

-

CooperSpecial Price $8.29 Regular Price $13.52This product is sold in increments of 1

17. Automotive Electrical

Overview:

Automotive electrical components encompass a wide range of devices and systems used in vehicles, including wiring harnesses, connectors, switches, relays, sensors, and electrical accessories, providing power distribution, control, and functionality for various automotive systems.

Top 5 Safety Risks:

- Electrical system malfunctions or failures leading to vehicle stalling, loss of power, or unsafe driving conditions.

- Fire hazards from short circuits, overheating, or electrical faults in wiring, connectors, or components.

- Exposure to hazardous voltages or currents during maintenance, repairs, or modifications of vehicle electrical systems.

- Improper installation or routing of wiring harnesses causing chafing, abrasion, or damage from heat, vibration, or environmental factors.

- Use of non-compliant or incompatible electrical components or modifications compromising vehicle safety, performance, or warranty.

Top 5 Safety Considerations:

- Follow manufacturer's specifications, wiring diagrams, and service procedures when working on automotive electrical systems.

- Disconnect battery terminals and ensure vehicle ignition is off before performing electrical repairs or modifications.

- Use insulated tools, gloves, and eye protection when handling electrical components to prevent shocks or injuries.

- Inspect and test electrical connections, wires, and components regularly to detect and address issues before they escalate.

- Avoid overloading electrical circuits, fuse panels, or accessory connections with excessive current draw or incompatible devices.

Top 10 FAQs:

- Q: How do I troubleshoot electrical problems in my vehicle? A: Start by checking fuses, relays, and connectors for signs of damage or corrosion, and use a multimeter to test voltage, continuity, and resistance in electrical circuits.

- Q: Can I replace automotive fuses with higher amperage ones to prevent them from blowing? A: No, using higher amperage fuses can lead to electrical overloads, component damage, and fire hazards. Always replace fuses with the correct amperage rating specified by the vehicle manufacturer.

- Q: What is the purpose of a relay in automotive electrical systems? A: Relays are used to control high-current devices or circuits with low-current signals, providing isolation and protection for sensitive control systems.

- Q: How do I prevent electrical corrosion in automotive connectors? A: Use dielectric grease or corrosion inhibitors on connector contacts, and inspect connectors regularly for signs of corrosion or oxidation.

- Q: Can I install aftermarket electrical accessories in my vehicle? A: Yes, but ensure proper installation, wiring, and compatibility with the vehicle's electrical system to avoid damage, malfunctions, or safety hazards.

Product Recommendations:

Automotive Electrical - Explore a comprehensive selection of automotive electrical components, accessories, and tools for maintenance, repairs, upgrades, and customizations, ensuring safety, reliability, and performance for your vehicle.

-

GenericSpecial Price $10.49 Regular Price $16.02This product is sold in increments of 1

-

PeakSpecial Price $7.49 Regular Price $11.57This product is sold in increments of 1

-

LoctiteSpecial Price $178.79 Regular Price $280.76This product is sold in increments of 1

-

Motor MedicSpecial Price $6.99 Regular Price $10.78This product is sold in increments of 1

-

Elevate OutdoorSpecial Price $301.99 Regular Price $475.19This product is sold in increments of 1

-

Elevate OutdoorSpecial Price $602.49 Regular Price $950.34This product is sold in increments of 1

-

CRCSpecial Price $203.29 Regular Price $319.09This product is sold in increments of 1

-

NocoSpecial Price $160.99 Regular Price $249.6This product is sold in increments of 1

Conclusion: Prioritizing Safety in Electrical Products

Electrical safety is paramount in both consumer and commercial applications, where the risks associated with electrical products can have severe consequences. Understanding the potential hazards and implementing appropriate safety measures is essential for protecting individuals, property, and the environment.

By following the guidelines outlined in this comprehensive shopping guide, buyers can make informed decisions when selecting electrical products, mitigating safety risks, and ensuring compliance with regulations and standards. From electrical tools to automotive components, each product category presents unique challenges and considerations, emphasizing the importance of thorough research, proper training, and adherence to best practices.

At GoVets, we prioritize safety and reliability in our extensive range of electrical products, offering high-quality solutions from trusted brands to meet the diverse needs of consumers, businesses, and industries. Explore our catalog today to discover top-rated electrical tools, equipment, and accessories, backed by our commitment to excellence and customer satisfaction.

Remember, safety should always come first when working with electrical products. Stay informed, stay vigilant, and stay safe.

- Staying Warm and Powered: Electrical Solutions for Winter Emergencies

- Mastering Cable Management: Electrical Raceways, Service Poles and Alternatives

- Understanding the Different Types of Electrical Enclosures: A Comprehensive Guide

- Comprehensive Guide to Conduits, Cables, and Pipe Management in Electrical Systems

- Understanding the Distinction: High Voltage vs. Low Voltage vs. Standard Electrical Applications

- Veteran Spotlight

- GoVets Solutions

- Buying Guides & Projects

- Shopping Trends

- Prime Contractor Resources

- Business & Entrepreneur Resources

- GoVets Giving

- Online Security and Shopping Safety

- GoVets Top Selling Products

- Veteran Resources

- Product Spotlights

- Technology Updates

- GoVets Medallion Updates

- Government Updates

- GoVets Capabilities

- Press Releases

- Promotion Updates

- Industry Trends