9 Micrometer Must-Haves: Your Ultimate Guide to Precision Measurement Tools

Introduction

Welcome to the Ultimate Guide to Micrometers, your complete shopping companion. Micrometers are precision instruments essential for various industries, from manufacturing to maintenance. Whether you're a seasoned professional or a beginner, understanding the nuances of different micrometer types can significantly impact your work quality and efficiency. In this comprehensive guide, we delve into various micrometer categories, their applications, reasons to use them, FAQs, and product recommendations. Let's embark on a journey through the world of micrometers!

- Micrometers: Precision Measuring Essentials

- Bench Micrometers: Benchtop Precision

- Depth Micrometers: Delving into Depth Measurement

- Inside Micrometers & Sets: Internal Precision

- Micrometer Calibration Standards & Sets: Ensuring Measurement Accuracy

- Micrometer Heads: Precision Measuring Accessories

- Outside Micrometers & Sets: Precise Measurements for External Features

- Specialty Micrometers: Tailored Solutions for Unique Measurement Needs

- Micrometer Torque Wrenches: Precise Torque Measurement Solutions

1. Micrometers: Precise Measurements at Your Fingertips

Micrometers are precision measuring tools used for accurately determining small distances or thicknesses. They provide measurements with high accuracy and are indispensable in industries requiring precision engineering.

Typical Applications:

- Quality Control: Micrometers ensure precise measurements in manufacturing processes, maintaining product quality standards.

- Engineering: Engineers use micrometers for dimensional analysis, ensuring parts fit together accurately in assemblies.

- Automotive Industry: Micrometers are vital for measuring engine components and ensuring precise fits for optimal performance.

- Aerospace: Micrometers play a crucial role in aerospace manufacturing, where precision is paramount for safety and performance.

- Metalworking: Machinists rely on micrometers for precise metal cutting and shaping operations.

Top 5 Reasons to Use Micrometers:

- Accuracy: Micrometers offer high precision, allowing measurements to be made to within thousandths of an inch or micron.

- Versatility: With various types available, micrometers can measure outer dimensions, depths, and even internal features.

- Durability: Constructed from sturdy materials, micrometers are built to withstand rigorous industrial environments.

- Efficiency: Micrometers enable quick and repeatable measurements, improving productivity and reducing errors.

- Standardization: Micrometers adhere to strict calibration standards, ensuring consistency and reliability in measurements.

Top 10 FAQs about Micrometers:

- What is a micrometer used for?

- Micrometers are used to measure small distances or thicknesses with high precision.

- How accurate are micrometers?

- Micrometers typically offer accuracy within microns or thousandths of an inch, depending on the model.

- What are the different types of micrometers?

- Common types include outside micrometers, inside micrometers, depth micrometers, and specialty micrometers.

- How do you read a micrometer?

- Reading a micrometer involves interpreting the main scale and the rotating thimble scale to obtain the measurement.

- What is the difference between digital and analog micrometers?

- Digital micrometers display measurements digitally, while analog micrometers use a vernier scale for reading.

- How do you calibrate a micrometer?

- Micrometers can be calibrated using precision calibration standards or by professional calibration services.

- What is the price range for micrometers?

- Micrometers vary widely in price depending on type, brand, and accuracy, ranging from affordable to high-end models.

- Can micrometers measure depth?

- Yes, depth micrometers are specifically designed to measure the depth of holes, slots, or recesses.

- Are there micrometers for specialized applications?

- Yes, specialty micrometers exist for unique measurement requirements, such as ball micrometers for spherical objects.

- How do you maintain micrometers?

- Proper maintenance involves keeping micrometers clean, storing them in protective cases, and regular calibration checks.

Product Recommendations: Micrometers

2. Bench Micrometers: Precision on the Workbench

Bench micrometers are designed for measuring large or heavy workpieces that cannot be accommodated by handheld micrometers. They provide stability and accuracy for benchtop operations.

Typical Applications:

- Machine Shops: Bench micrometers are commonly used in machine shops for measuring large machined parts.

- Tool and Die Making: Toolmakers rely on bench micrometers for precise measurements during tool fabrication.

- Metal Fabrication: Bench micrometers ensure accuracy in metal fabrication processes, such as cutting and bending.

- Woodworking: Woodworkers use bench micrometers for measuring lumber thickness and machining tolerances.

- Manufacturing Plants: Bench micrometers find applications in various manufacturing processes requiring high precision.

Top 5 Reasons to Use Bench Micrometers:

- Stability: Bench micrometers offer a stable platform for measuring heavy or bulky workpieces.

- Accuracy: With large anvils and precise mechanics, bench micrometers deliver accurate measurements consistently.

- Versatility: They can accommodate a wide range of workpiece sizes, from small components to large assemblies.

- Ease of Use: Bench micrometers are user-friendly, with intuitive controls and clear measurement readouts.

- Efficiency: They expedite measurement tasks by providing a stable setup and reducing the need for repositioning.

Top 10 FAQs about Bench Micrometers:

- How do bench micrometers differ from handheld micrometers?

- Bench micrometers are stationary devices designed for measuring larger workpieces, while handheld micrometers are portable and used for smaller components.

- Can bench micrometers measure internal dimensions?

- Some bench micrometers come with interchangeable anvils or attachments for measuring internal dimensions.

- What types of materials can be measured with bench micrometers?

- Bench micrometers can measure various materials, including metals, plastics, and wood.

- Are bench micrometers suitable for fieldwork?

- Due to their size and weight, bench micrometers are primarily used in workshop settings rather than for fieldwork.

- How are bench micrometers calibrated?

- Calibration of bench micrometers is typically performed using precision gauge blocks or calibration standards.

- What is the maximum measurement range of bench micrometers?

- The measurement range varies depending on the model, with some bench micrometers capable of measuring several inches or centimeters.

- Are bench micrometers suitable for non-contact measurements?

- Bench micrometers are contact instruments and require physical contact with the workpiece for measurement.

- Can bench micrometers measure thickness variations?

- Yes, bench micrometers can detect thickness variations within their measurement range.

- Do bench micrometers require regular maintenance?

- Routine maintenance includes cleaning, lubrication, and periodic calibration checks to ensure accuracy.

- Are there accessories available for bench micrometers?

- Yes, accessories such as different-sized anvils, extension rods, and calibration standards are available for bench micrometers.

Product Recommendations: Bench Micrometers

3. Depth Micrometers: Precision in Depth Measurement

Depth micrometers are specialized instruments used for measuring the depth of holes, slots, or recesses. They provide accurate depth measurements essential for various machining and engineering applications.

Typical Applications:

- Metalworking: Depth micrometers are indispensable in metalworking processes for measuring hole depths and machined features.

- Woodworking: Woodworkers use depth micrometers to measure the depth of drill holes, mortises, and other woodworking joints.

- Automotive Industry: Depth micrometers play a vital role in automotive manufacturing for measuring cylinder bores and engine components.

- Aerospace: Aerospace engineers rely on depth micrometers for measuring critical dimensions in aircraft components.

- Maintenance and Repair: Depth micrometers are used in maintenance workshops for measuring wear depths and part dimensions.

Top 5 Reasons to Use Depth Micrometers:

- Accuracy: Depth micrometers provide precise depth measurements, ensuring dimensional accuracy in machined parts.

- Versatility: They can measure various depths and feature sizes, making them suitable for diverse applications.

- Ease of Use: Depth micrometers feature clear scale markings and simple operation, facilitating accurate measurements.

- Durability: Constructed from robust materials, depth micrometers withstand harsh industrial environments.

- Efficiency: Depth micrometers expedite depth measurement tasks, reducing setup time and improving workflow efficiency.

Top 10 FAQs about Depth Micrometers:

- What is the measuring range of depth micrometers?

- Depth micrometers typically have a measuring range of several inches or centimeters, depending on the model.

- Can depth micrometers measure blind holes?

- Yes, depth micrometers are designed to measure the depth of blind holes accurately.

- Are there digital depth micrometer models available?

- Yes, digital depth micrometers feature electronic displays for easy reading of measurements.

- Can depth micrometers measure step heights?

- Some depth micrometer models come with step measuring capabilities for measuring height differences.

- How do you zero a depth micrometer?

- Zeroing a depth micrometer involves ensuring the measuring faces are clean and free from debris before taking measurements.

- What is the resolution of depth micrometers?

- The resolution varies depending on the model but is typically within microns or thousandths of an inch.

- Are depth micrometers suitable for measuring curved surfaces?

- Depth micrometers are primarily designed for flat surface measurements and may not be suitable for curved surfaces.

- Can depth micrometers measure internal dimensions?

- Yes, depth micrometers can measure internal dimensions such as hole depths accurately.

- Are depth micrometers compatible with different units of measurement?

- Yes, depth micrometers may offer measurement readings in both metric and imperial units.

- Do depth micrometers require calibration?

- Yes, regular calibration ensures the accuracy of depth micrometer measurements and should be performed as per manufacturer guidelines.

Product Recommendations: Depth Micrometers

4. Inside Micrometers & Sets: Precision Measuring for Internal Features

Inside micrometers, also known as bore micrometers, are specialized tools for measuring internal dimensions such as bore diameters, groove widths, and hole depths. They are indispensable in industries requiring precise internal measurements.

Typical Applications:

- Machining: Inside micrometers are extensively used in machining operations for measuring bore sizes and depths.

- Engine Building: Automotive technicians use inside micrometers for measuring cylinder bores and engine components.

- Toolmaking: Tool and die makers rely on inside micrometers for precision measurements during tool fabrication.

- Maintenance and Repair: Inside micrometers find applications in maintenance workshops for measuring worn or damaged internal components.

- Quality Control: Inside micrometers ensure the dimensional accuracy of internal features in manufactured parts.

Top 5 Reasons to Use Inside Micrometers:

- Accuracy: Inside micrometers provide precise measurements of internal dimensions, ensuring proper fits and clearances.

- Versatility: They can measure various internal features such as bores, grooves, and recesses, making them versatile tools.

- Ease of Use: Inside micrometers feature simple designs with intuitive controls, facilitating easy and accurate measurements.

- Durability: Constructed from durable materials, inside micrometers withstand harsh industrial environments and frequent use.

- Interchangeable Heads: Some inside micrometer sets come with interchangeable heads for measuring a wide range of bore sizes.

Top 10 FAQs about Inside Micrometers & Sets:

- What is the measuring range of inside micrometers?

- Inside micrometers typically have a measuring range of several inches or centimeters, depending on the model.

- Can inside micrometers measure blind holes?

- Yes, inside micrometers are designed to measure the depth of blind holes accurately.

- What types of internal features can inside micrometers measure?

- Inside micrometers can measure bore diameters, groove widths, hole depths, and other internal features.

- Are there digital inside micrometer models available?

- Yes, digital inside micrometers feature electronic displays for easy reading of measurements.

- How do you use inside micrometers to measure bores?

- Inside micrometers are inserted into the bore and expanded until they contact the bore walls, providing an accurate measurement.

- Can inside micrometers measure irregularly shaped bores?

- Inside micrometers are suitable for measuring round and cylindrical bores but may not be ideal for irregular shapes.

- Do inside micrometers require calibration?

- Yes, regular calibration ensures the accuracy of inside micrometer measurements and should be performed as per manufacturer guidelines.

- What is the resolution of inside micrometers?

- The resolution varies depending on the model but is typically within microns or thousandths of an inch.

- Are inside micrometers compatible with different units of measurement?

- Yes, inside micrometers may offer measurement readings in both metric and imperial units.

- Do inside micrometers come with interchangeable heads?

- Some inside micrometer sets include interchangeable heads for measuring different bore sizes, providing versatility in applications.

Product Recommendations: Inside Micrometers & Sets

5. Micrometer Calibration Standards & Sets: Ensuring Measurement Accuracy

Micrometer calibration standards and sets are essential for verifying and maintaining the accuracy of micrometer measurements. They provide reference standards for calibration and ensure consistent measurement results.

Typical Applications:

- Quality Assurance: Calibration standards are used in quality control processes to ensure the accuracy of measurement instruments.

- Laboratories: Calibration laboratories use micrometer calibration sets for verifying the accuracy of micrometers and other measuring tools.

- Manufacturing Facilities: Micrometer calibration sets are employed in manufacturing facilities to calibrate micrometers used in production processes.

- Maintenance Workshops: Maintenance technicians use calibration standards to verify the accuracy of micrometers before use in repair and maintenance tasks.

- Research and Development: Calibration sets play a crucial role in research and development environments where precise measurements are essential.

Top 5 Reasons to Use Micrometer Calibration Standards & Sets:

- Accuracy Verification: Calibration standards ensure the accuracy of micrometer measurements, maintaining quality standards.

- Traceability: Calibration sets provide traceability to national or international measurement standards, ensuring measurement consistency.

- Compliance: Calibration standards help organizations comply with quality management system requirements and industry standards.

- Preventive Maintenance: Regular calibration prevents measurement errors and ensures reliable measurement results.

- Quality Assurance: Calibration sets support quality assurance efforts by verifying the accuracy of measurement instruments used in critical processes.

Top 10 FAQs about Micrometer Calibration Standards & Sets:

- What is included in a micrometer calibration set?

- A micrometer calibration set typically includes precision gauge blocks or reference standards for calibration.

- How often should micrometers be calibrated?

- Micrometers should be calibrated regularly as per manufacturer recommendations or industry standards.

- Can calibration standards be used for other measuring instruments?

- Some calibration standards may be suitable for calibrating other measuring instruments besides micrometers.

- Are there different calibration standards for digital and analog micrometers?

- Calibration standards are available for both digital and analog micrometers, tailored to specific measurement requirements.

- Can micrometer calibration be performed in-house?

- In-house calibration is possible with the right equipment and expertise, but many organizations prefer external calibration services for accuracy and traceability.

- What is the accuracy of micrometer calibration standards?

- Micrometer calibration standards typically have accuracies within microns or thousandths of an inch, depending on the grade.

- Are there international standards for micrometer calibration?

- Yes, organizations such as ISO and ASTM publish standards for micrometer calibration procedures and requirements.

- How do you verify the accuracy of micrometer calibration standards?

- Calibration standards are verified using traceable measurement instruments or reference standards with known accuracies.

- Do micrometer calibration sets come with certificates of calibration?

- Yes, reputable calibration sets come with certificates of calibration documenting traceability to national or international standards.

- Can micrometer calibration be performed without specialized equipment?

- While basic calibration checks can be performed using precision gauge blocks, accurate calibration typically requires specialized calibration equipment and expertise.

Product Recommendations: Micrometer Calibration Standards & Sets

6. Micrometer Heads: Precision Measuring Accessories

Micrometer heads, also known as micrometer screw heads, are precision measuring accessories used in conjunction with micrometer anvils or spindles. They provide fine adjustments for achieving accurate measurements in various applications.

Typical Applications:

- Machine Tools: Micrometer heads are commonly used in machine tools for precise positioning and measurement adjustments.

- Metrology: Metrologists use micrometer heads for building custom measurement setups and specialized measurement applications.

- Calibration Laboratories: Micrometer heads find applications in calibration laboratories for building calibration fixtures and setups.

- Precision Engineering: Engineers use micrometer heads for fine adjustments and precise measurements in precision engineering applications.

- Tool and Die Making: Toolmakers rely on micrometer heads for setting tooling and making precise adjustments in tool and die making processes.

Top 5 Reasons to Use Micrometer Heads:

- Fine Adjustment: Micrometer heads offer precise fine adjustment capabilities, allowing for accurate measurements in tight tolerance applications.

- Compatibility: They are compatible with various micrometer types, including outside, inside, and depth micrometers.

- Versatility: Micrometer heads can be used in custom measurement setups and fixtures for specialized measurement applications.

- Durability: Constructed from high-quality materials, micrometer heads are durable and withstand frequent use in industrial environments.

- Ease of Use: Micrometer heads feature user-friendly controls and clear markings, making them easy to operate and adjust.

Top 10 FAQs about Micrometer Heads:

- What is the purpose of micrometer heads?

- Micrometer heads provide fine adjustment capabilities for achieving precise measurements with micrometers.

- How do you install micrometer heads?

- Micrometer heads are typically attached to the micrometer spindle or anvil using set screws or mounting adapters.

- Can micrometer heads be used with digital micrometers?

- Yes, micrometer heads are compatible with both analog and digital micrometers, providing fine adjustment capabilities.

- Do micrometer heads come with different thread sizes?

- Yes, micrometer heads are available in various thread sizes to accommodate different micrometer spindle or anvil threads.

- Are there micrometer heads with digital readouts?

- Some micrometer heads feature digital readouts for precise adjustment and measurement readouts.

- What is the resolution of micrometer heads?

- The resolution varies depending on the model but is typically within microns or thousandths of an inch.

- Are micrometer heads suitable for non-contact measurements?

- Micrometer heads are contact instruments and require physical contact with the workpiece for measurement.

- Can micrometer heads be used for depth measurements?

- Micrometer heads are primarily designed for linear measurements and may not be suitable for depth measurements.

- Do micrometer heads require calibration?

- While micrometer heads themselves may not require calibration, they are often used in conjunction with calibrated micrometers for accurate measurements.

- Are there accessories available for micrometer heads?

- Yes, accessories such as mounting adapters, extension rods, and calibration standards are available for micrometer heads to enhance their versatility.

Product Recommendations: Micrometer Heads

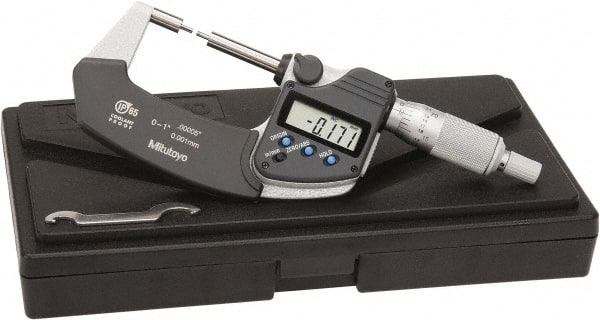

7. Outside Micrometers & Sets: Precise Measurements for External Features

Outside micrometers, also known as micrometer calipers, are precision measuring tools used for measuring the external dimensions of objects with high accuracy. They are versatile instruments suitable for a wide range of applications.

Typical Applications:

- Machining: Outside micrometers are extensively used in machining operations for measuring workpiece diameters and thicknesses.

- Quality Control: They play a vital role in quality control processes for verifying the dimensional accuracy of manufactured parts.

- Engineering: Engineers use outside micrometers for dimensional analysis and tolerance verification in various engineering applications.

- Metalworking: Metalworkers rely on outside micrometers for precise measurements during metal cutting and shaping operations.

- Automotive Industry: Outside micrometers find applications in the automotive industry for measuring engine components and body parts.

Top 5 Reasons to Use Outside Micrometers:

- Accuracy: Outside micrometers offer high precision, allowing for accurate measurements of external dimensions with repeatability.

- Versatility: They can measure various external features such as diameters, thicknesses, and lengths, making them versatile tools.

- Ease of Use: Outside micrometers feature simple designs with easy-to-read scales and intuitive operation, facilitating quick measurements.

- Durability: Constructed from sturdy materials, outside micrometers withstand rugged industrial environments and frequent use.

- Efficiency: They expedite measurement tasks by providing quick and accurate readings, improving workflow efficiency.

Top 10 FAQs about Outside Micrometers & Sets:

- How do you read an outside micrometer?

- Reading an outside micrometer involves interpreting the main scale and the rotating thimble scale to obtain the measurement.

- What is the accuracy of outside micrometers?

- Outside micrometers typically offer accuracy within microns or thousandths of an inch, depending on the model.

- Can outside micrometers measure thicknesses?

- Yes, outside micrometers can measure the thickness of flat or cylindrical objects accurately.

- Are there digital outside micrometer models available?

- Yes, digital outside micrometers feature electronic displays for easy reading of measurements.

- Can outside micrometers measure curved surfaces?

- Outside micrometers are suitable for measuring curved surfaces with consistent diameters, such as shafts and cylinders.

- What is the maximum measurement range of outside micrometers?

- The measurement range varies depending on the model, with some outside micrometers capable of measuring several inches or centimeters.

- Do outside micrometers require regular calibration?

- Yes, regular calibration ensures the accuracy of outside micrometer measurements and should be performed as per manufacturer guidelines.

- Are outside micrometers compatible with different units of measurement?

- Yes, outside micrometers may offer measurement readings in both metric and imperial units.

- Can outside micrometers measure non-cylindrical objects?

- Outside micrometers are primarily designed for cylindrical objects but can measure flat surfaces with consistent thickness.

- Do outside micrometers come with accessories?

- Yes, accessories such as calibration standards, extension rods, and protective cases are available for outside micrometers to enhance their functionality.

Product Recommendations: Outside Micrometers & Sets

8. Specialty Micrometers: Tailored Solutions for Unique Measurement Needs

Specialty micrometers encompass a wide range of specialized measurement tools designed for unique measurement applications. From spherical measurements to thread pitch micrometers, they cater to diverse measurement requirements across industries.

Typical Applications:

- Ball Micrometers: Used for measuring spherical objects such as ball bearings and lenses in precision engineering.

- Thread Pitch Micrometers: Designed for measuring the pitch diameter of screw threads in manufacturing and machining.

- Tube Micrometers: Tailored for measuring the wall thickness of tubes and pipes in plumbing and metalworking.

- Blade Micrometers: Used for measuring the thickness of cutting blades and knives in metal fabrication and woodworking.

- Gear Tooth Micrometers: Specifically designed for measuring gear tooth thicknesses and profiles in gear manufacturing.

Top 5 Reasons to Use Specialty Micrometers:

- Precision: Specialty micrometers offer precise measurements tailored to specific applications, ensuring accuracy and reliability.

- Customization: They are designed to meet unique measurement needs, with specialized features and configurations for various applications.

- Efficiency: Specialty micrometers expedite measurement tasks by providing dedicated solutions for specific measurement requirements.

- Accuracy: With calibrated scales and precision mechanisms, specialty micrometers deliver accurate measurements consistently.

- Versatility: Despite their specialized nature, specialty micrometers offer versatility in addressing diverse measurement challenges across industries.

Top 10 FAQs about Specialty Micrometers:

- What are ball micrometers used for?

- Ball micrometers are used for measuring spherical objects such as ball bearings and lenses with high precision.

- Can thread pitch micrometers measure thread angles?

- Thread pitch micrometers are specifically designed for measuring the pitch diameter of screw threads and do not measure thread angles.

- Are there digital specialty micrometer models available?

- Yes, some specialty micrometers come with digital readouts for precise measurements and ease of use.

- How do tube micrometers differ from outside micrometers?

- Tube micrometers feature rounded anvils for measuring the thickness of tubes and pipes, whereas outside micrometers have flat anvils for measuring external diameters.

- Can blade micrometers measure serrated edges?

- Blade micrometers can measure the thickness of straight-edged blades but may not be suitable for measuring serrated edges.

- Do specialty micrometers require calibration?

- Yes, regular calibration ensures the accuracy of specialty micrometer measurements and should be performed as per manufacturer guidelines.

- Are specialty micrometers suitable for non-industrial applications?

- While designed for industrial applications, specialty micrometers can be used in various fields requiring precise measurements, including hobbyist and educational settings.

- What is the measurement range of specialty micrometers?

- The measurement range varies depending on the type of specialty micrometer, with some models capable of measuring small dimensions in microns or larger dimensions in inches.

- Can specialty micrometers measure irregularly shaped objects?

- Specialty micrometers are designed for specific measurement tasks and may not be suitable for irregularly shaped objects unless tailored for such applications.

- Do specialty micrometers come with warranties?

- Yes, reputable specialty micrometers often come with warranties covering defects in materials and workmanship, providing peace of mind to users.

Product Recommendations: Specialty Micrometers

9. Micrometer Torque Wrenches: Precise Torque Measurement Solutions

Micrometer torque wrenches combine the functionality of torque wrenches with micrometer precision for accurate torque measurement in mechanical applications. They are essential tools in industries requiring precise torque control for assembly and maintenance tasks.

Typical Applications:

- Automotive Repair: Micrometer torque wrenches are used in automotive repair shops for tightening bolts and fasteners to precise torque specifications.

- Aerospace Industry: Aerospace engineers rely on micrometer torque wrenches for assembling aircraft components with exact torque values.

- Manufacturing: Micrometer torque wrenches find applications in manufacturing facilities for ensuring consistent torque levels in production processes.

- Equipment Maintenance: Maintenance technicians use micrometer torque wrenches for tightening critical fasteners in machinery and equipment.

- Construction: Builders and contractors use micrometer torque wrenches for assembling structural components with specified torque requirements.

Top 5 Reasons to Use Micrometer Torque Wrenches:

- Precision: Micrometer torque wrenches provide precise torque measurements, ensuring proper tightening of fasteners to prevent under or over-tightening.

- Accuracy: With calibrated scales and micrometer adjustments, they offer accurate torque readings within tight tolerances.

- Versatility: Micrometer torque wrenches are suitable for various applications, from automotive repair to aerospace assembly, providing versatility in torque control.

- Ease of Use: They feature intuitive controls and clear torque scales, making them easy to operate and adjust for different torque requirements.

- Durability: Constructed from robust materials, micrometer torque wrenches withstand rugged industrial environments and frequent use, ensuring long-term reliability.

Top 10 FAQs about Micrometer Torque Wrenches:

- What is the measuring range of micrometer torque wrenches?

- Micrometer torque wrenches typically have a torque measuring range spanning from a few foot-pounds to several hundred foot-pounds, depending on the model.

- Can micrometer torque wrenches measure both clockwise and counterclockwise torque?

- Yes, most micrometer torque wrenches are bi-directional and can measure torque in both clockwise and counterclockwise directions.

- Do micrometer torque wrenches require calibration?

- Yes, regular calibration ensures the accuracy of micrometer torque wrench measurements and should be performed as per manufacturer guidelines.

- Are there digital micrometer torque wrench models available?

- Yes, some micrometer torque wrenches feature digital displays for precise torque readouts and ease of use.

- Can micrometer torque wrenches be used for precision assembly tasks?

- Yes, micrometer torque wrenches are ideal for precision assembly tasks requiring accurate torque control, such as engine assembly and equipment installation.

- What is the accuracy of micrometer torque wrenches?

- The accuracy of micrometer torque wrenches varies depending on the model but is typically within a few percentage points of the indicated torque value.

- Can micrometer torque wrenches be used for dynamic torque measurements?

- While primarily designed for static torque measurements, some micrometer torque wrench models may be suitable for dynamic torque applications within specified limits.

- How do you adjust the torque setting on micrometer torque wrenches?

- Micrometer torque wrenches feature micrometer adjustments or torque setting knobs that allow users to set the desired torque value accurately.

- Are micrometer torque wrenches suitable for high-torque applications?

- Yes, there are micrometer torque wrench models designed for high-torque applications, providing precise torque control in demanding environments.

- Do micrometer torque wrenches come with calibration certificates?

- Yes, reputable micrometer torque wrenches often come with calibration certificates documenting traceability to national or international standards, ensuring measurement accuracy.

Product Recommendations: Micrometer Torque Wrenches

Wrapping it up

In conclusion, micrometers and their various types play indispensable roles in precision measurement across industries. From the simple but essential outside micrometers to the specialized tools like micrometer torque wrenches, these instruments ensure accuracy, reliability, and efficiency in dimensional measurement tasks. Whether in manufacturing, engineering, maintenance, or research, the right micrometer tool can make all the difference in achieving precise results and maintaining quality standards. Explore the diverse range of micrometer options available to find the perfect fit for your specific measurement needs.